|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-20-2

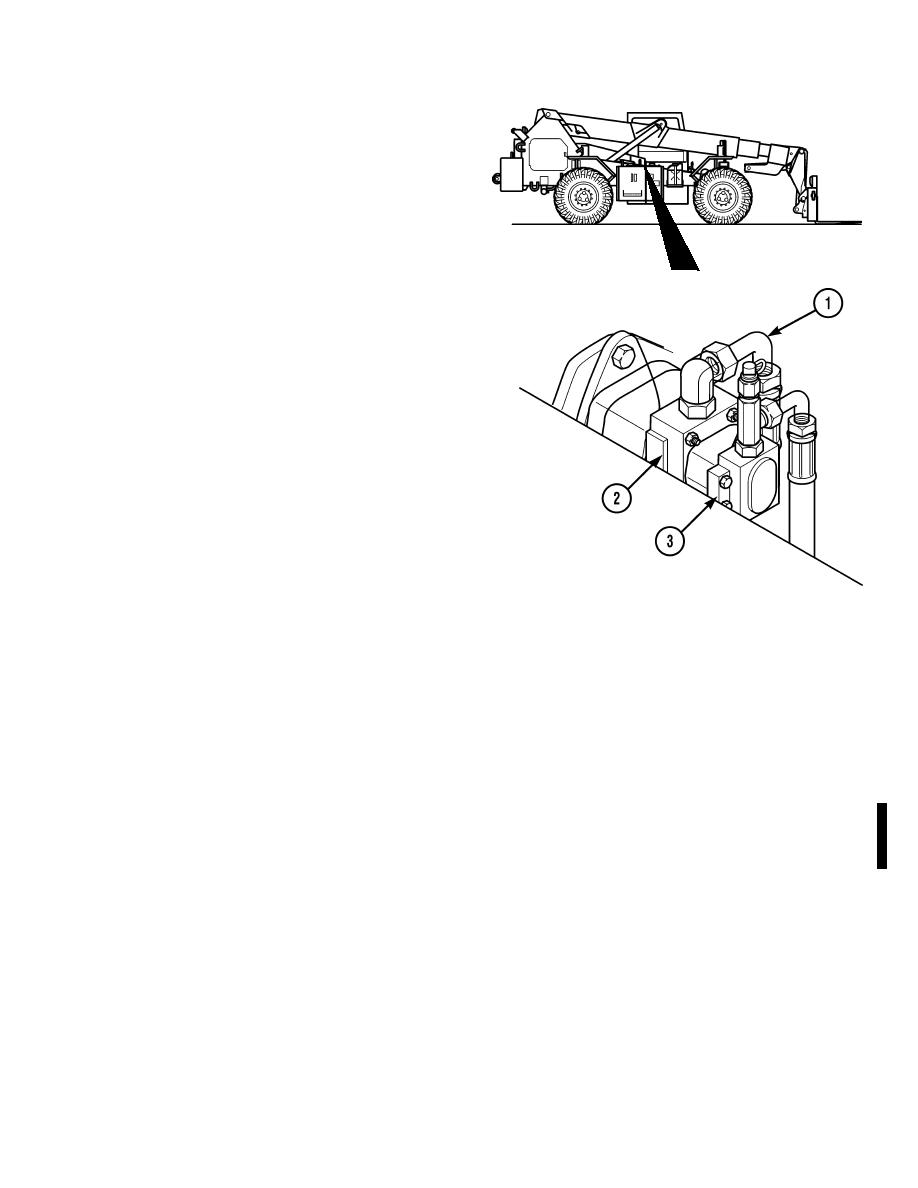

(1)

Prepare and set up in-line flowmeter for

testing.

(2)

Make hydraulic connections to flowmeter.

(a)

Tag, mark, and disconnect pump outlet

hose (1) from pump section being

TR00003

tested.

(b)

Connect test hose from outlet side of

section being tested to inlet port of

flowmeter.

(c)

Connect hydraulic hose (1) removed in

Step (2)(a) above to outlet port of

flowmeter.

NOTE

Hydraulic pumps are tested at specific

engine RPMs. STE/ICE kit may be used

to monitor engine speed.

(3)

Start engine (TM 10-3930-673-10).

(4)

If large pump section (2) is being tested,

adjust engine speed to 2500 RPM and

pressure to 2500 PSI (17237.5 kPa). Read

TR00877

flow in GPM.

(5)

If small pump section (3) is being tested, adjust engine speed to 1800 RPM and pressure to 2500 PSI

(17237.5 kPa). Read flow in GPM.

NOTE

Hydraulic pump sections must meet following specifications:

Large pump section - 47.0-55.0 GPM @ 2500 RPM.

Small pump section - 14.6-16.9 GPM @ 2500 RPM.

If either section fails to meet or exceed specifications, replace pump. Refer to b. Removal and

(6)

c. Installation for pump replacement instructions.

(7)

Turn engine off (TM 10-3930-673-10) and allow hydraulic system to cool down before proceeding.

(8)

Disconnect test hose from outlet side of section tested and inlet port of flowmeter.

(9)

Disconnect hydraulic hose (1) from outlet port of flowmeter and connect hose to outlet side of section

tested.

Change 1

18-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |