|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CARRIAGE TILT CYLINDER REPAIR - CONTINUED

0307 00

DISASSEMBLY - CONTINUED

9.

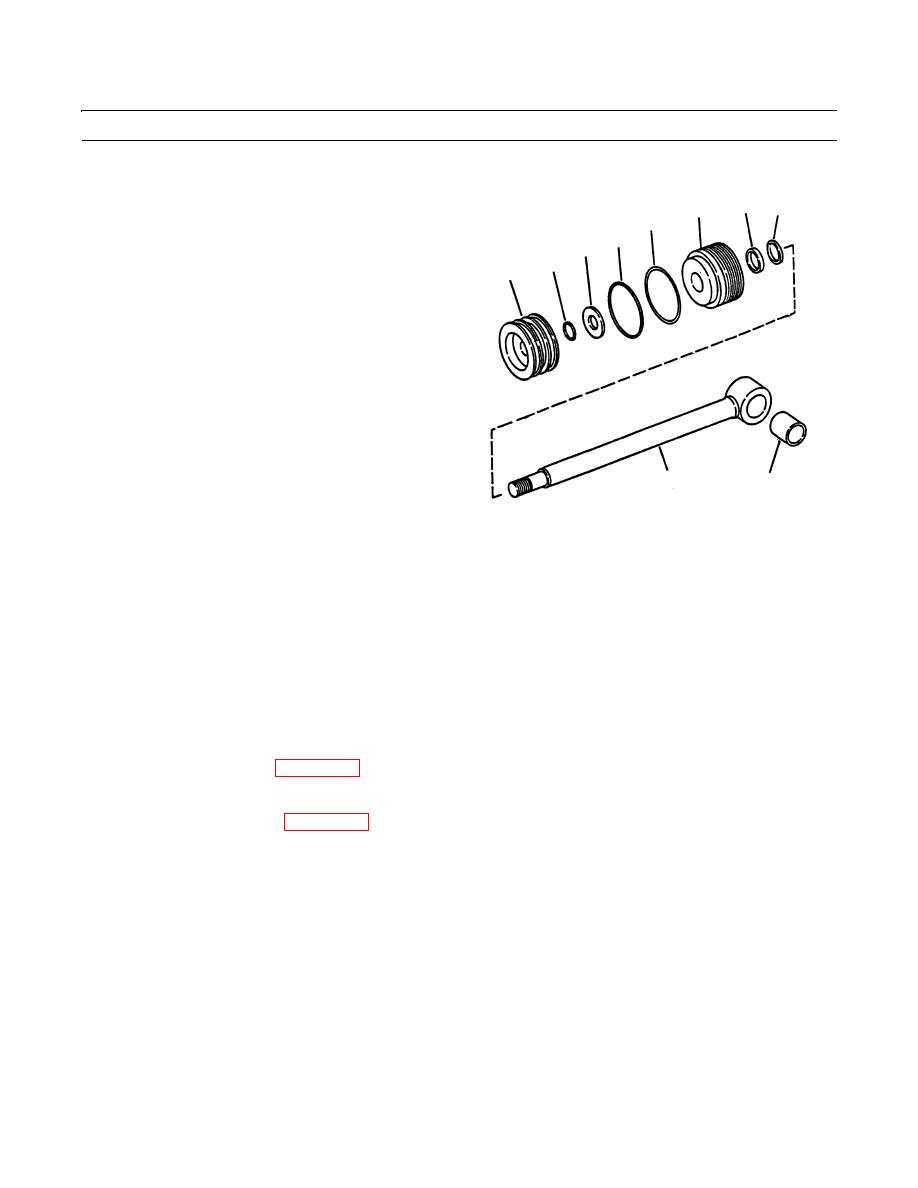

Remove piston (10) and O-ring (11). Discard O-ring.

14

15

3

10.

Remove washer (12) and slide gland (3) off rod (2).

13

5

11.

Remove O-ring (5) and back-up ring (13) from gland

12

11

(3). Discard O-ring and back-up ring.

10

2

16

409-1392

CAUTION

Do not nick or scratch seal groove during removal of seal and rod wiper. Failure to follow this precaution

will cause part damage.

NOTE

Note direction that lip of seal is facing before removal.

12.

Remove seal (14) and rod wiper (15) from inside of gland (3). Discard seal.

13.

Remove bushing (16).

CLEANING

See Cleaning instructions (WP 0316 00).

INSPECTION

See Inspection instructions (WP 0317 00).

ASSEMBLY

NOTE

Wipe all sealing surfaces on cylinder clean and dry. Apply film of clean hydraulic oil to all seals as they are

installed.

1.

Install bushing (16).

2.

Install new seal (14) and rod wiper (15) inside gland (3). Ensure that seal (14) lip is positioned the same way as it was

before disassembly.

3.

Install new back-up ring (13) and new O-ring (5) on outside diameter of gland (3).

4.

Slide gland (3) and washer (12) onto rod (2).

5.

Lubricate piston (10) inner diameter with clean lubricating oil. Install new O-ring (11) inside bore of piston (10).

0307 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |