|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

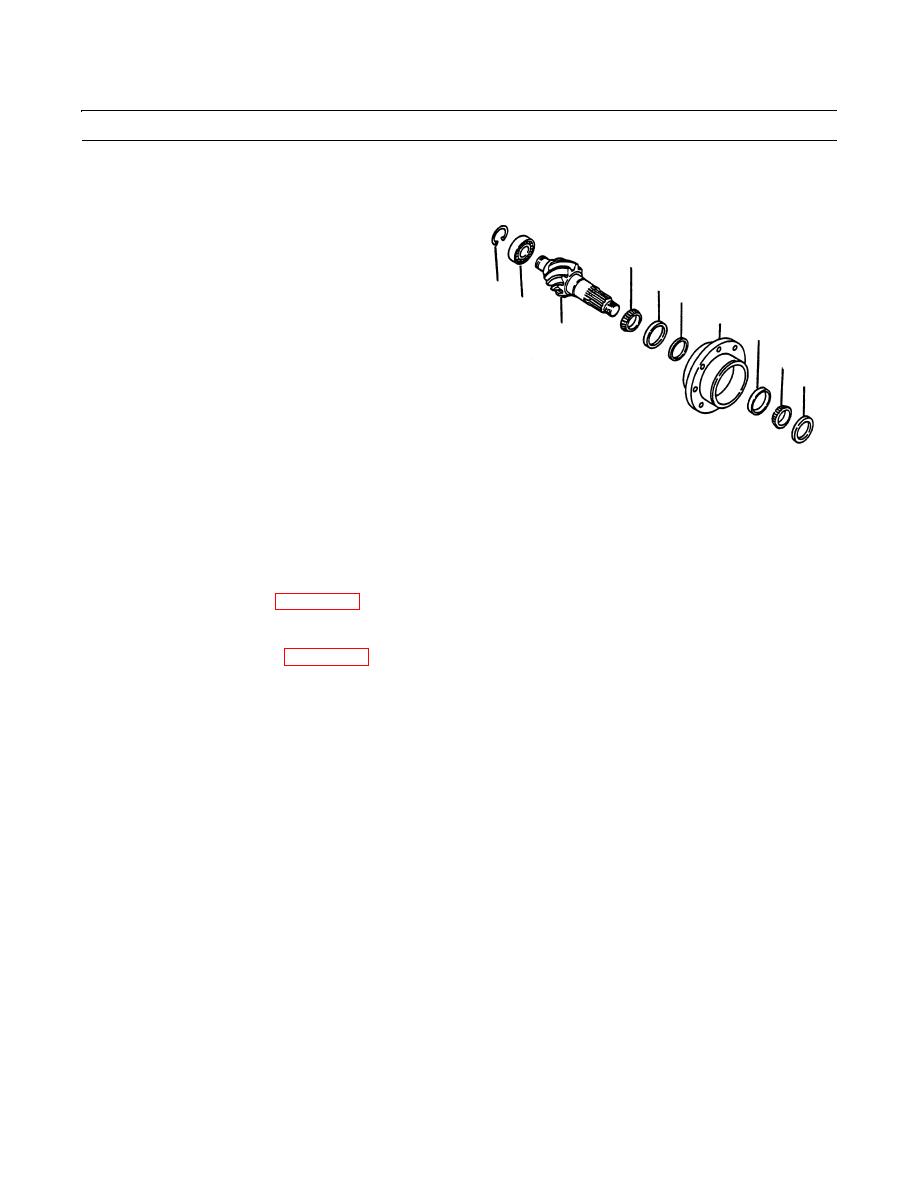

REAR DIFFERENTIAL CARRIER ASSEMBLY MAINTENANCE - CONTINUED

0298 00

DISASSEMBLY - CONTINUED

19.

Remove pinion bearing cage thrust washer (30).

20.

Place bevel pinion (26) and bearing cage (27) in a

press with splined end of pinion at the top of assembly.

32

21.

Support bearing cage (27) under flange area with

34

blocks.

33

36

37

27

22.

Use a press to remove bevel pinion (26) from bearing

35

cage (27).

26

31

23.

Remove outer bearing cone (31) from bearing cage

30

(27).

24.

Use puller and remove inner bearing cone (32) and

bearing spacer (33) from bevel pinion (26).

25.

Use puller to remove inner bearing cup (34) and outer

409-1287

bearing cup (35) from bearing cage (27).

26.

Install a soft metal cover over vise jaws to protect bevel pinion (26). Place bevel pinion in a vise.

27.

Remove snap ring (36) from end of bevel pinion (26).

28.

Remove bearing (37) from spigot end of bevel pinion (26).

CLEANING

See Cleaning instructions (WP 0316 00).

INSPECTION

See Inspection instructions (WP 0317 00).

ASSEMBLY

NOTE

Pinion and ring gears are a matched set. If replacement of ring gear or pinion gear is necessary, replace both

gears as a set.

1.

Use a press and suitable driver to install inner bearing cup (34) and outer bearing cup (35) into bearing cage (27). Be

sure bearing cups are tight against bottom of cage bore.

2.

Use a press and suitable sleeve driver to install inner bearing cone (34) on bevel pinion (26).

3.

If necessary, use a press and suitable sleeve driver to install spigot bearing (37) onto spigot end of bevel pinion (26).

4.

Install snap ring (36) into groove on end of bevel pinion (26).

5.

Apply a thin film of clean lubricating oil to inner and outer bearing cups (34 and 35) and bearing cones (31 and 32).

6.

Install bearing spacer (33) on bevel pinion against inner bearing cone (32).

7.

Install bevel pinion (29) and bearing assembly into bearing cage.

8.

Use a press and suitable sleeve driver and install outer bearing cone (31) on bevel pinion tight against bearing spacer

(27).

9.

Install pinion bearing thrust washer (30).

10.

Install companion yoke (23), nut (21) and washer (22) on bevel pinion (26). If necessary, use a press to push yoke on

pinion. Companion yoke (23) must be against thrust washer (30).

0298 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |