|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

TURBOCHARGER ASSEMBLY REPAIR (152 HP) - CONTINUED

0281 00

ASSEMBLY - CONTINUED

CAUTION

Do not allow impeller to turn when installing locknut. Failure to prevent impeller from turning will result in

improper balance and premature component failure.

NOTE

Locknut has left-hand treads, be sure to turn locknut counterclockwise when installing.

21.

Install new locknut (9) onto shaft. Torque locknut to 120 lb-in (163 Nm).

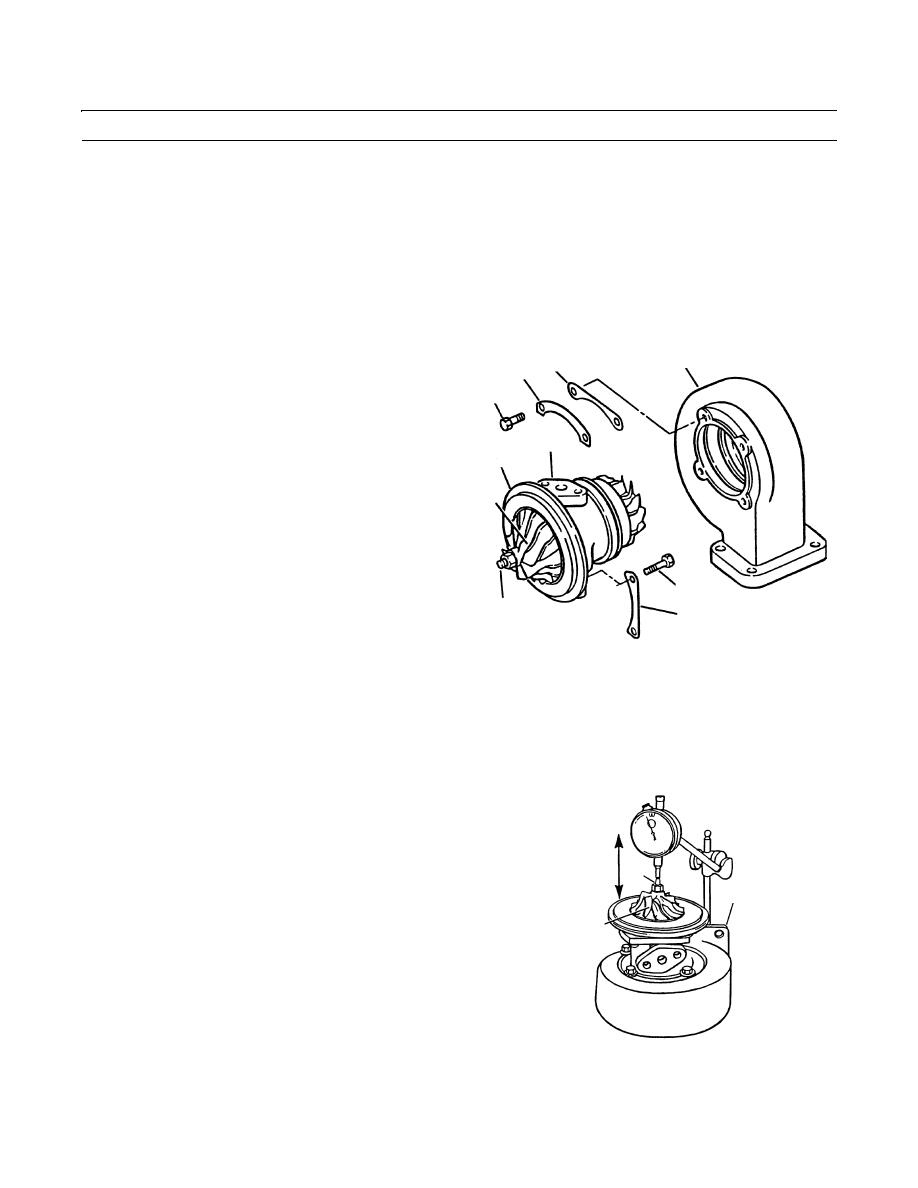

22.

Install bearing housing (2), impeller (10) and shaft

3

23

22

(24) into turbine housing (3) as an assembly.

21

23.

Align match marks on bearing housing (2) and turbine

housing (3) that were made at disassembly.

24.

Apply Loctite 767-64 to new capscrew (21) threads.

2

13

25.

Install two new lock plates (22), one clamping plate

(23), and four new capscrews (21) into turbine hous-

10

ing.

26.

Torque capscrews (21) to 100 lb-in. (136 Nm).

27.

Bend lock plate (22) tabs up to secure capscrews (21).

11

24

12

409-1081

28.

Install two new lock plates (12) and four capscrews (11) through bearing housing (2) and into diffuser (13).

29.

Torque capscrews (11) to 50 lb-in. (68 Nm).

CAUTION

Ensure scribe marks on diffuser, bearing housing and turbine housing are properly aligned during assembly.

Failure to properly align components could result in premature component failure.

30.

Bend lock plate (12) tabs up to secure capscrews (11).

31.

Attach a dial indicator to the turbine housing (3).

Adjust dial indicator so that plunger is against shaft

(24) end.

24

32.

Set dial indicator to zero.

3

33.

Move shaft (24) and impeller (10) assembly back and

10

forth and read end play on dial indicator. If end play is

less than 0.001 in. (.0254 mm), or greater than 0.003

in. (.0762 mm), disassemble turbocharger and check

for problem. Replace defective parts and assemble.

34.

To measure radial clearance of shaft (24), attach a dial

indicator to turbine housing. Adjust dial indicator

409-1082

plunger so that plunger is against end of impeller (13)

between fins and jamnut (9).

0281 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |