|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

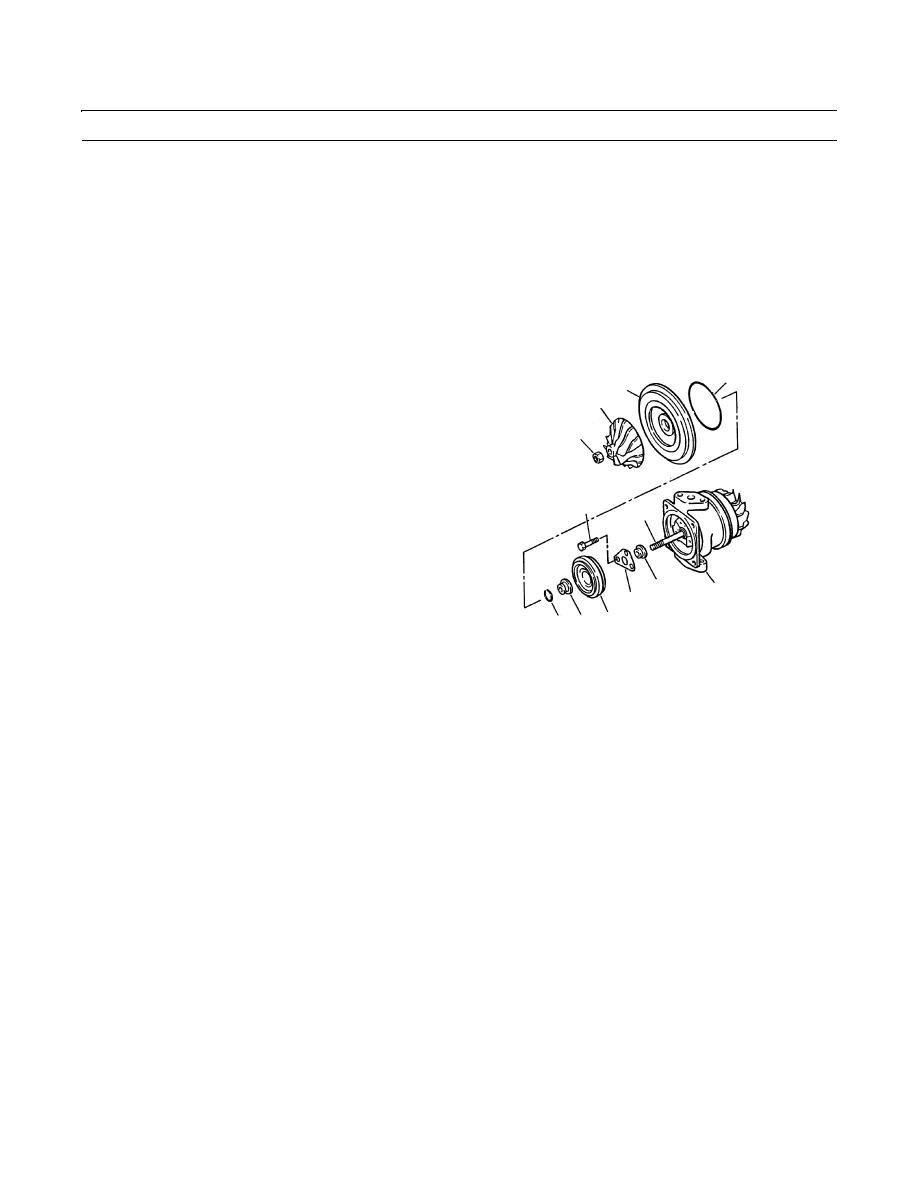

TURBOCHARGER ASSEMBLY REPAIR (152 HP) - CONTINUED

0281 00

ASSEMBLY - CONTINUED

CAUTION

When installing thrust collar, be sure balance mark on collar is aligned with shaft balance mark. Mark top

surface of thrust collar so alignment can be verified after installing thrust bearing. Failure to align balance

marks could cause premature component failure.

10.

Install thrust collar (20) onto shaft and wheel (24).

11.

Apply clean lubrication oil to new thrust bearing (19).

12.

Install new thrust bearing (19) and secure with three new capscrews (18). Torque capscrews to 40 lb-in. (54 Nm).

13.

Install oil baffle (17) onto shaft (24).

14

13

14.

Install new split ring oil seal (16) onto oil slinger (15).

10

15.

Mark top surface of oil slinger (15) in line with bal-

9

ance mark.

16.

Apply clean lubrication oil to outside of oil slinger

(15).

17.

Install oil slinger (15) and new split ring oil seal (16)

18

24

into diffuser (13). Install new ring seal (14) into dif-

fuser (13).

18.

Align balance marks on shaft (24) and oil slinger (15).

20

2

19

409-1079

16 15 17

19.

Install oil slinger (15) and diffuser (13), as an assembly, onto shaft (24).

CAUTION

When installing impeller, be sure to align balance marks on shaft and impeller. Failure to do so could

cause premature component failure.

Do not move bearing housing when installing impeller. Moving bearing housing during impeller instal-

lation will cause improper balance and premature component failure.

20.

Install impeller (10) onto shaft (24).

0281 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |