|

|||

|

|

|||

|

Page Title:

EPA ENGINE HARNESS RETROFIT REPLACEMENT (new engine) |

|

||

| ||||||||||

|

|

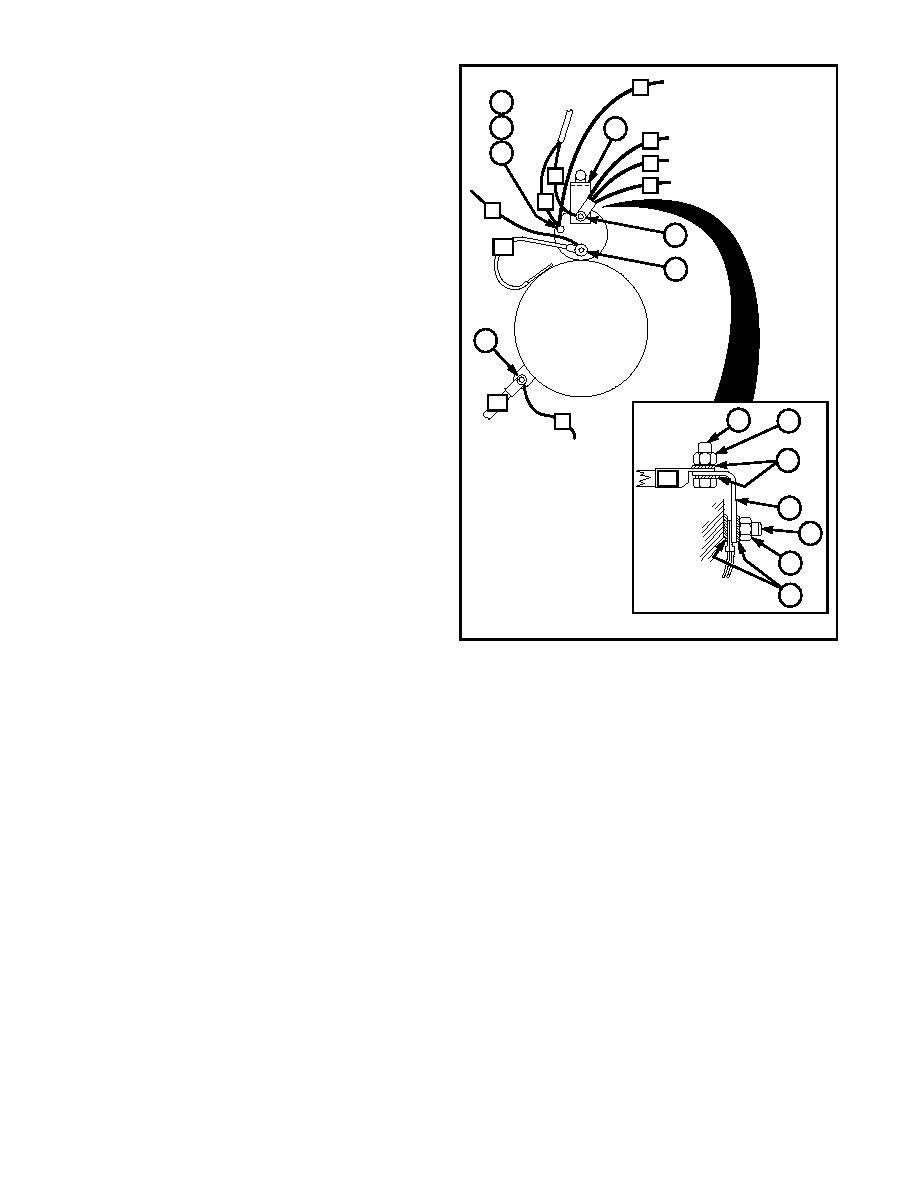

11. EPA ENGINE HARNESS RETROFIT

REPLACEMENT (new engine) (cont)

38

16

d. (From the kit) install lockwasher #8310016 (6),

terminal strap #6621412 (7), wires "9," "9," "T" &

15

7

39

"39" to the starter solenoid (+) stud (8) with

14

lockwasher #8310046 (6) and nut #8305438

9

(10). Tighten to 12 lb-ft. (Figure 21).

T

9

e. Attach positive battery cable "POS" with (from the

S

9A

kit) screw #8303620 (11), lockwashers #8307026

(12), on terminal strap (7) and nut #8305008 (13).

8

(Figure 21).

WHT

17

f. Attach wires "38" and "S" onto the starter

solenoid stud (14) with (from the kit) lockwasher

#8307052 (15) and nut #8310077 (16). Tighten to

25 lb-in. (Figure 21).

18

g. Attach wire "9A'" and white ground cable "WHT,"

from the starter case housing, to the starter

solenoid ground (-) stud (17). Tighten to 6 lb-ft.

(Figure 21).

GND

AFTER INSTALLATION OF ENGINE

11

13

M

a. Connect new harness fuel shut off electrical wire

"7" to original fuel shut off electrical wire "7," that

12

was connected to the old engines fuel shut off

POS

solenoid (Not shown).

7

b. Attach wire "M" along with the frame ground

cable "GND" to the lower left starter mount

8

capscrew (18). (Figure 21). Torque the lower left

10

capscrew to 32 lb-ft (43,4 Nm).

c. Connect new electrical wire "2" to any frame

6

engine mount capscrew; for grounding the new

EPA wire harness (Not shown).

SM1720

Figure 21

0326 00-14

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |