|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

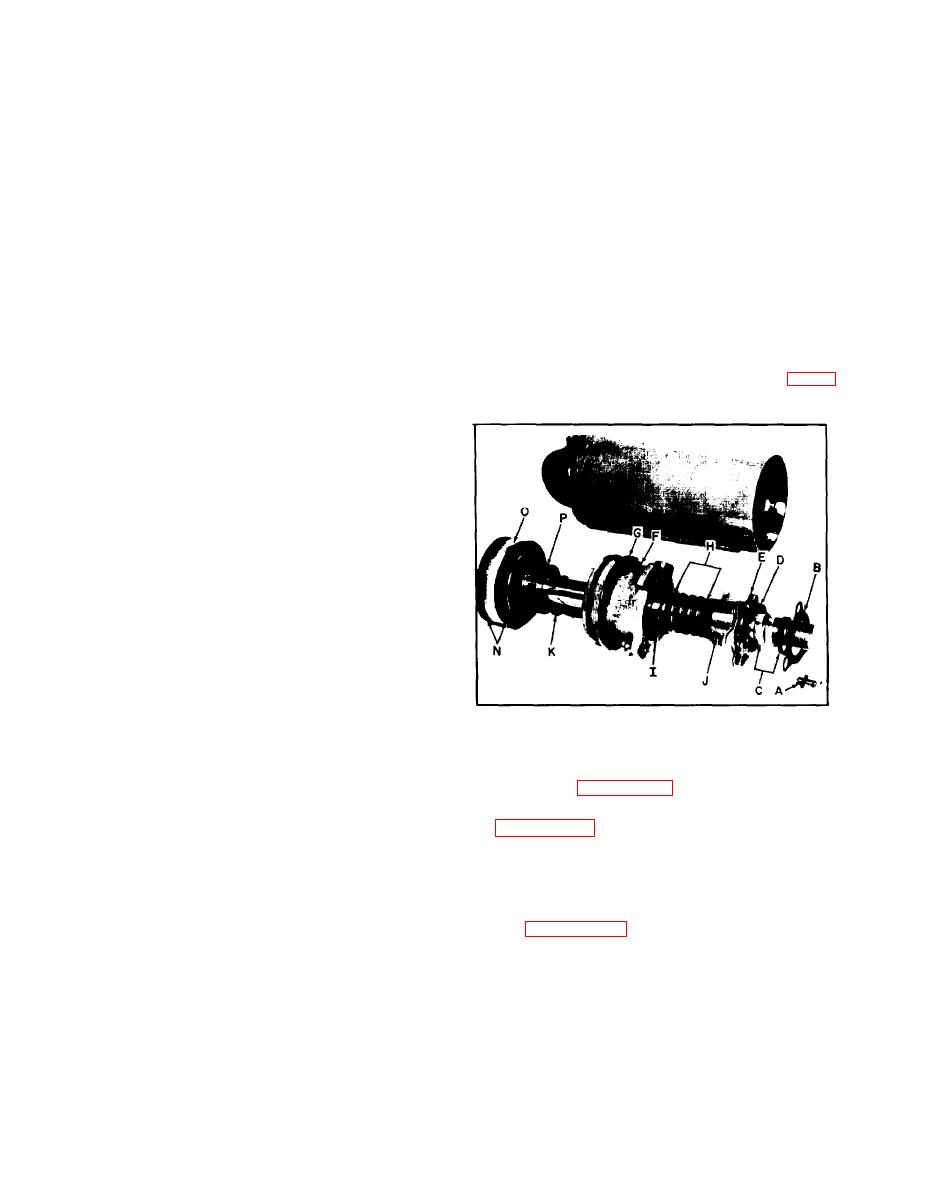

Legend for Figure 5-160

Ring Segment

17.

Plate

25.

Bushing

Tilt Cyl. Assy.

9.

1.

Boot

18.

Lockwasher

26.

Packing Set

10.

Barrel

2.

Retainer

19.

Capscrew

27.

Shim

11.

u-cup

3.

Bushing

20.

Lub-Fitting

28.

Retainer

12.

W e a r Ring

4.

Adaptor

21.

Gland

29.

Lockwasher

13.

Spacer

5.

22.

Spacer

30.

Retainer

14.

Capscrew

O-Ring

6.

Spring

23.

Retainer

31.

15.

Wiper

Back-up Ring

7.

Packing Kit.

24.

Capscrew

32.

Pin

16.

Gland Assy.

8.

b. Remove tilt cylinder pivot pins at rear

b. Install a new back-up ring and O-ring on

mounting and at upright. Remove tilt cylinder

the check valve plug with the O-ring toward

from machine.

the spring and bail. Place the bail and spring

c . An exploded view of the tilt cylinder is

in the body and install the plug. Be sure the

shown on the preceding page to aid in dis-

hole in the plug lines up with the stud hole

assembly and reassembly of the unit. See figure

in the body.

5-160.

C. Install lower spool seal and back-up ring

on valve spool, making sure that scarfed ends

of back-up ring are closed up and correctly

seated.

d. Install one "C" washer at each end of the

centering spring. The fiat side of the "C"

washer faces away from the spring when installed.

e . Install the upper spool quad ring on the

s p o o l , and install the O-ring on the spring

cover sleeve face.

f . Carefully position spring cover and sleeve

over the spool and against valve body. Install

spring cover screws and tighten to IO foot/

pounds torque.

g. After installation of valve and connection

to operating lever linkage, check valve opera-

t i o n . Spools should return to neutral auto-

matically when the control lever is released.

Figure 5-161.

Tilt Cylinder Components.

The centering spring force is approximately 40

pounds. If more force is necessary, check

5-135 DISASSEMBLY.

linkage for binds.

a. Refer to figure 5-160 for detailed parts

5-133 TILT CYLINDERS.

identification and proceed as outlined below:

5-134 REMOVAL. Should it be found that the

b. Figure 5-161 shows components of the tilt

tilt cylinders will not hold upright at desired

cylinder and body. Refer to this figure and

a n g l e o f t i l t , it will be necessary to remove

remove three retainer bolts (A) securing the

and disassemble cylinder to determine the

cover (6). seal guard kit (C), retainer (D) and

faulty condition.

shims (E). Pull these components from end of

cylinder and piston rod.

a . Tilt upright to full forward position,

disconnect hose lines at front and rear of

c. See figure 5-162 for gland details and

cylinder.

loosen gland bolts (F), using suitable wrench.

Then, using a screwdriver, rotate each bolt

x

xxxxxxxxxxxxxxxxxxxxxxx

until head is against gland assembly.

X

X

X

WARNING

X

d. Now tap gland assembly inward into cylinder,

X

X

being careful not to mar, nick, scratch, etc.,

X

X

SECURE UPRIGHT WITH A CHAIN TO PREVENT

X

the piston rod. Use a wooden or plastic mallet

X

X

that does not have a metal frame that might

X

FALLING.

contact piston rod when tapping gland.

X

X

x

xxxxxxxxxxxxxxxxxxxxxxx

5-96

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |