|

|||

|

|

|||

|

Page Title:

BEARING REPLACEMENT AND LUBRICATION |

|

||

| ||||||||||

|

|

Slip rings which are rough or out of round

to re-lubricate and reuse the bearing.

should be trued in a lathe to .002 inch maximum

To remove the bearing from the slip ring

indicator reading. Remove only enough material

end frame, press out with a tube or col-

to make the rings smooth and round. Finish with

lar that just fits inside the end frame

400-grain or finer polishing cloth and blow away

Press from the outside of the

housing.

a l l dust.

housing towards the inside.

BEARING REPLACEMENT AND LUBRICATION:

d. To install a new bearing, place a fiat

plate over the bearing and press in from

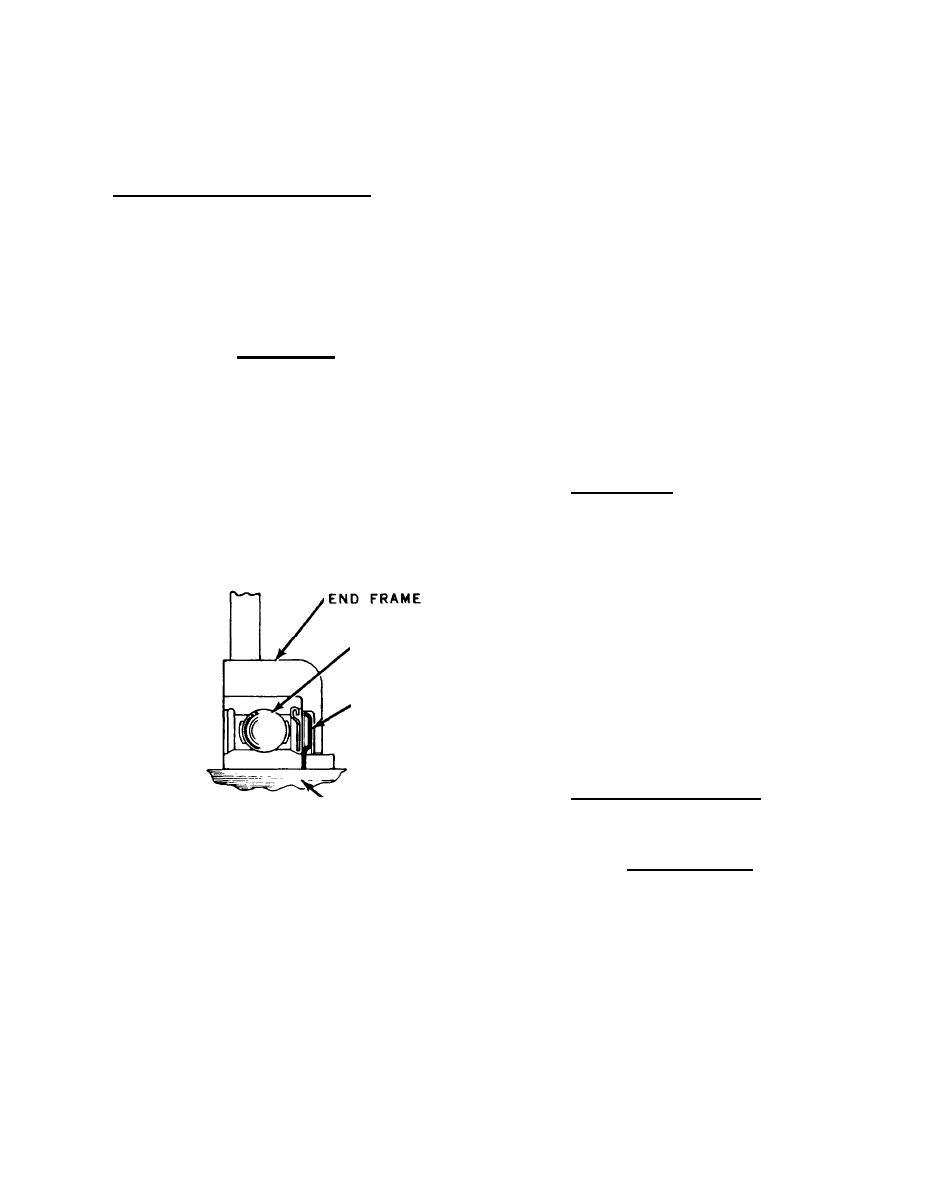

a. The bearing in the drive end frame can be

the outside toward the inside of the

removed by detaching the retainer plate

frame until the bearing is flush with

screws and then pressing the bearing from

the outside of the end frame. Support

the end frame. If the bearing is in satis-

the inside of the frame with a hollow

factory condition and is to be reused, it

cylinder to prevent breakage of the end

should be filled one-quarter full with

frame. Use extreme care to avoid mis-

s p e c i a l grease (Part number 1800574)

alignment or otherwise placing undue

stress on the bearing.

CAUTION

e.

If the seal is separate from the bearing,

it is recommended that a new seal be in-

DO NOT OVERFILL, AS THIS MAY CAUSE THE

stalled whenever the bearing is replaced

Press the seal in with the lip of the

BEARING TO OVERHEAT.

USE ONLY THE REC-

seal toward the rotor when assembled;

t h a t is, away from the bearing. Lightly

COMMENDED LUBRICANT (PER 01M00 LUBRICA-

c o a t the seal lip with oil to facilitate

assembly of the shaft into the bearing.

TION SPECIFICATIONS AND RECOMMENDATIONS).

5-67. REASSEMBLY:

b. To install a new bearing, press in with

Reassembly is the reverse of disassembly.

a tube or collar that just fits over the

Remember when assembling the pulley to secure

outer race, with the bearing and slinger

assembled into the end frame (as shown in

the rotor in a vise only tight enough to permit

tightening the shaft nut to 40-60 pound feet

plate 12343).

It is recommended that a

If excessive pressure is applied ag-

a i n s t the rotor, the assembly may become dis-

t o r t e d . To install the slip ring and frame as-

sembly to the rotor and drive end frame assembly,

remove the tape over the bearing and shaft, and

BEARING

make sure the shaft is perfectly clean after re-

moving the tape. Insert a rod through the hole

to hold up the brushes. Carefully

install the

shaft into the slip ring end frame assembly to

`SLINGER

avoid damage to the seal. After tightening the

t h r u - b o l t s , remove the brush retaining rod to

allow the brushes to fail down onto the slip

rings.

5-68. GENERATOR BENCH CHECK

\

ARMATURE

To check the generator in a test stand, proceed

SHAFT

a s follows:

Plate 12343. Drive End Bearing Assembly with

Slinger (some models use flat

IMPORTANT

washer instead of slinger)

GROUND POLARITY OF ENERGIZER AND GENE-

new retainer plate be installed if the

felt seal in the retainer plate is hard-

RATOR MUST BE THE SAME. USE A FULLY

ened or excessively worn. Fill the cavity

between the retainer plate and bearing with

CHARGED ENERGIZER OR BATTERY.

special lubricant called for in Step I.

c. The bearing in the slip ring end frame

should be replaced if its grease supply

is exhausted. No attempt should be made

5-50G

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |