|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b. Then reverse the lead connections to the

grounded heat sink and same terminal (or

If both readings are the same,

connector).

r e p l a c e the rectifier bridge. A good rec-

tifier bridge will give one high and one

low reading. Repeat this same test be-

tween the grounded heat sink and the other

two terminals, and between the insulated

heat sink and each of the three terminals.

This makes a total of six checks, with two

readings taken for each check.

c. The ohmmeter check of the rectifier bridge,

and of the diode trio as previously covered,

is a valid and accurate check. DO NOT re-

place either unit unless at least one pair

of readings is the same.

OHMMETER

OHMMETER

CAUTION

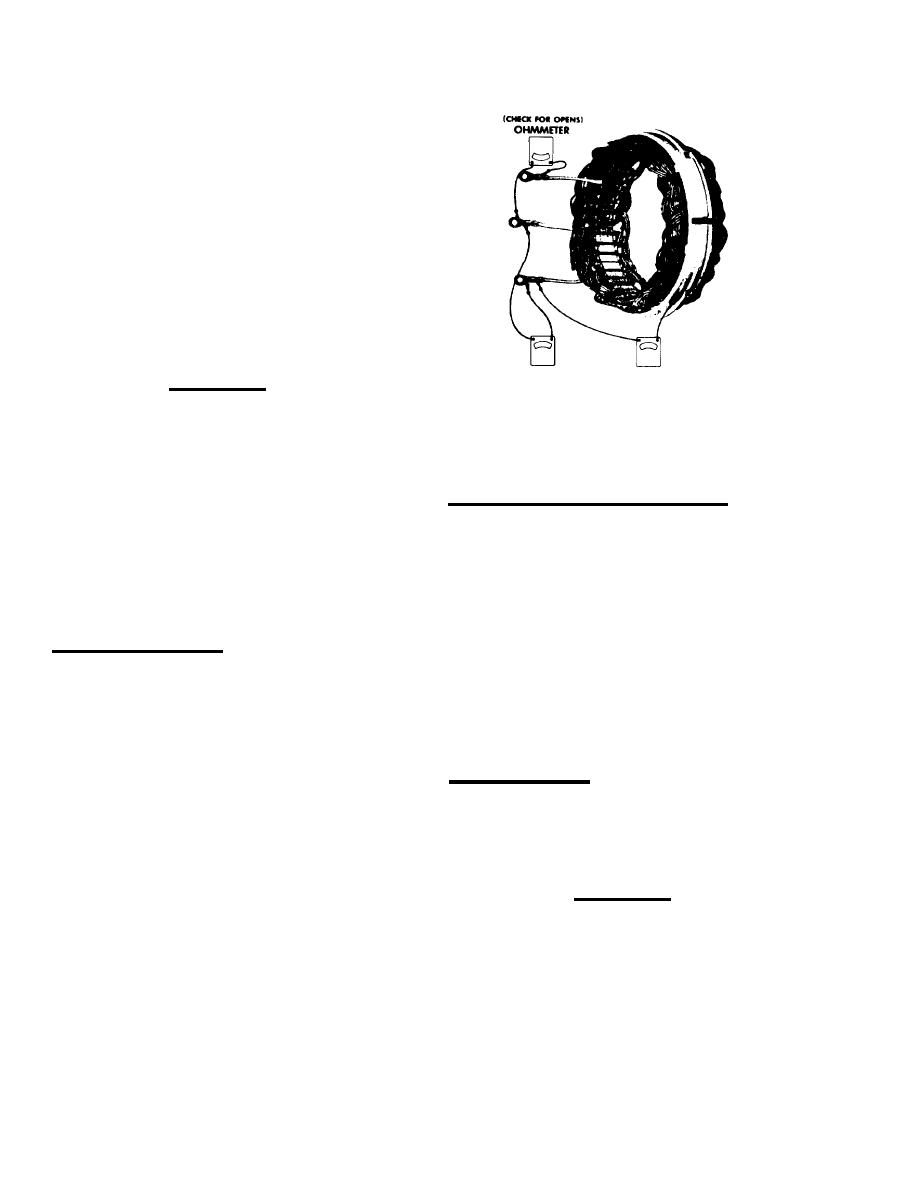

(CHECK FOR OPENS)

(CHECK FOR GROUNDS)

Plate 12342. Checking Stator Windings

DO NOT USE HIGH VOLTAGE TO CHECK THESE

shorted stator can cause the indicator

UNITS, SUCH AS A 110-VOLT TEST LAMP.

lamp to be on with the engine at low

speed.

d. To replace the rectifier bridge, remove

the attaching screws, and disconnect the

BRUSH HOLDER AND REGULATOR REPLACEMENT:

capacitor lead.

After removing the three attaching nuts,

NOTE

the stator and diode trio screw (plates 12340

and 12341). the brush holder and regulator may

There is an insulator between the insu-

be replaced by removing the two remaining screws.

lated heat sink and end frame (plate

12340). Rectifier bridges may vary in

Notice the two insulators located over the

appearance but are completely inter-

top of the brush clips in plate 12338, and that

changeable in these generators.

these two screws have special insulating sleeves

above the threads. The third mounting screw may

CHECKING STATOR WINDINGS:

If not,

or may not have an insulating sleeve.

this screw must not be interchanged with either

a. The stator windings may be checked with

one of the other two screws, as a ground may

a 110-volt test lamp or an ohmmeter.

result, causing no output or uncontrolled gener-

ator output. Requlators may vary in appearance

b. If the lamp lights, or if the meter rea-

but are completely interchangeable in these

ding is low when connected from any stator

lead to the frame, the windings are groun-

ded.

SLIP RING SERVICING:

c . If the lamp fails to light, or if the

I f the slip rings are dirty, they may be

meter reading is high when successively

cleaned and finished with 400-grain or finer

connected between each pair of stator

p o l i s h i n g cloth. Spin the rotor and hold the

leads on 10-S1 Series, the windings are

polishing cloth against the slip rings until

open (plate 12342).

they are clean.

CAUTION

THE ROTOR MUST BE ROTATED IN ORDER TO

CLEAN THE SLIP RINGS EVENLY; CLEANING

d. A short circuit in the stator windings

i s difficult to locate without laboratory

SLIP RINGS BY HAND WITHOUT SPINNING

test equipment due to the low resistance

of the windings. However, i f all other

ROTOR MAY RESULT IN FLAT SPOTS ON

electrical checks are normal and the gen-

erator fails to supply rated output, shor-

SLIP RINGS, CAUSING BRUSH NOISE.

Also, a

ted windings are indicated.

5-50F

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |