|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

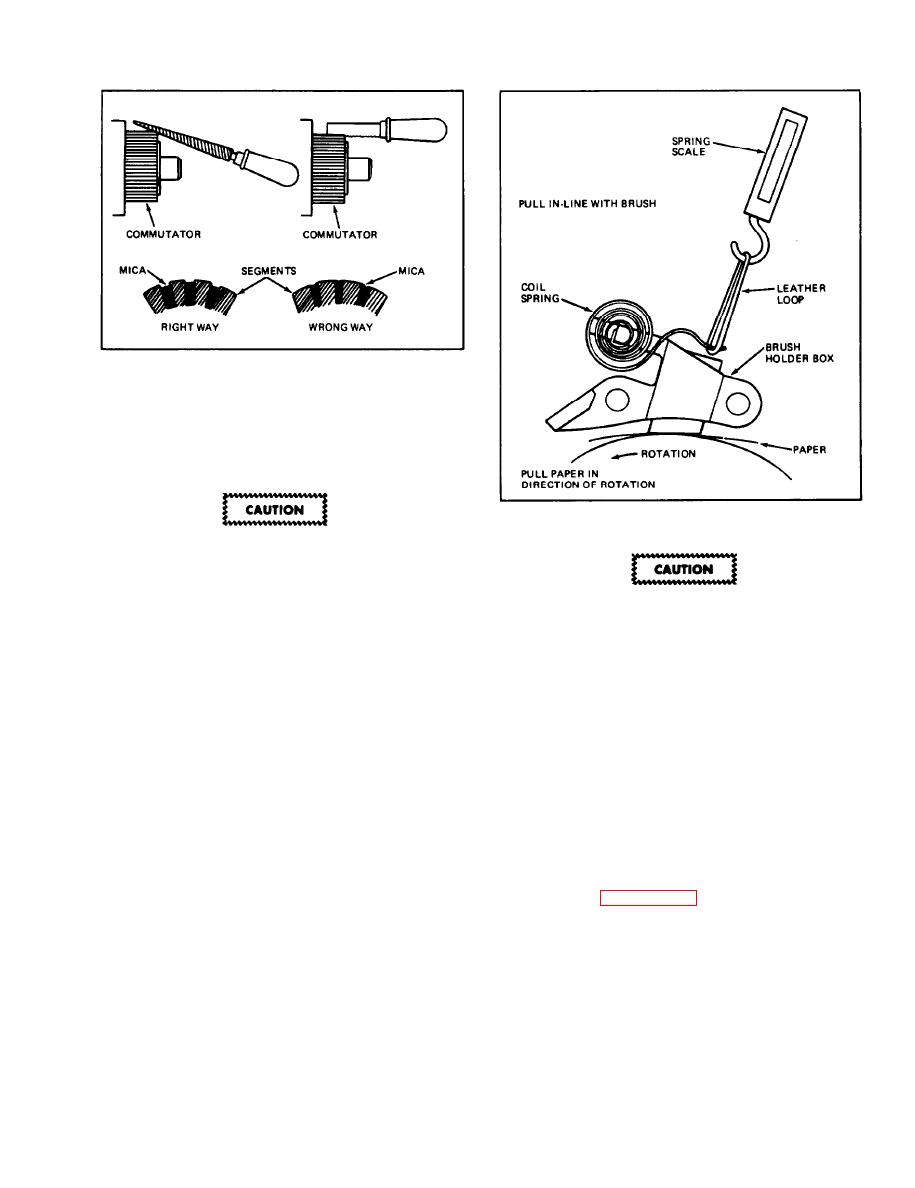

Figure 6-73. Undercutting Mica

Figure 5-74. Brush Spring Pressure Check

Meter needle will jump wildly; precautions

should be taken to avoid damage to

instrument.

Do not use silicone base varnishes.

STEP 4. To test armature for grounds, place one

R E P A I R . Carefully

5-58. COMMUTATOR

probe of test lamp on armature core or shaft and

inspect the commutator. If burned, rough or

p l a c e other probe on commutator bars. If lamp

out-of-round, it must be turned and the mica

lights, armature is grounded and must be repaired

undercut.

or replaced.

a. Place armature in a lathe and turn down

5-67. FIELD COILS TEST.

c o m m u t a t o r until true. Make certain cut is not

made on commutator riser bars as solder will be

a. To test for gounded fields, place one probe of

removed and weaken coil connections. Remain

test lamp on field frame and other probe on field

terminal. If lamp lights, field coils are grounded

approximately 3/16 inch from riser bars when

and must be replaced if ground cannot be located

cutting.

and repaired.

b. Undercut mica to a depth not exceeding 0.030

b. Paint or spray field coils and inside of motor

inch. Undercut must be full width of mica and flat

f r a m e with Class " F " a i r d r y i n g v a r n i s h . T h e

at bottom. See figure 5-73.

armature coils, core, and end of commutator bars,

and mica cone ring can be sprayed or painted with

c. Sand commutator lightly with No. 00

class " F " b a k i n g v a r n i s h . ( B a k e p e r v a r n i s h

sandpaper to remove any burrs left from

manufacturer's instructions.)

undercutting. Clean slots.

5-47

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |