|

|||

|

|

|||

|

Page Title:

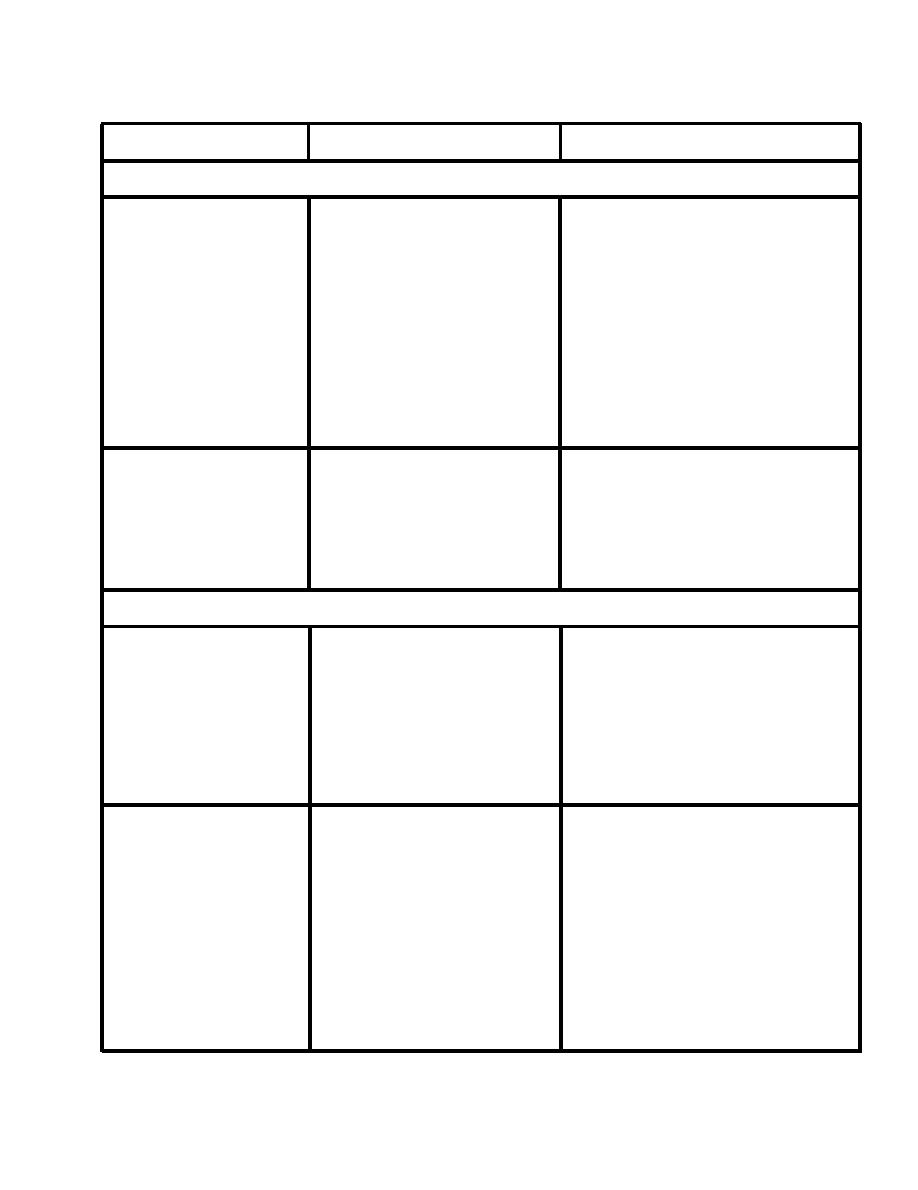

TABLE 4. TROUBLESHOOTING GUIDE - continued |

|

||

| ||||||||||

|

|

TABLE 4. TROUBLESHOOTING GUIDE (Continued)

REMEDY

PROBABLE CAUSE

TROUBLE

6. TRANSMISSION, CONVERTER & AXLE ADAPTER (Hydratork Drive) (Continued)

Clean screen.

Clogged sump screen

Transmission overheating

(continued)

Report to designated authority.

Insufficient oil to torque

converter and cooler

`Clean cooler.

Cooler clogged internally

stopping flow of oil

Report to designated authority.

Bushing in torque converter

impeller hub worn, allowing

oil to leak out

Refer to transmission pressure checks.

Slipping stator

Check capacity loads. Never overload.

Overloading machine

Machine has full power

and overheats

Clean core.

Radiator core clogged

externally

Report to designated authority.

Pressure regulator valve

sticking, giving low pressure

7. DRIVE AXLE

Replace worn parts with new.

Badly worn parts

Continuous axle noise

Replace tires.

Unevenly worn tires

Adjust correctly.

Improperly adjusted wheel

bearing

Add sufficient lubricant of correct

Lack of lubricant

grade.

Adjust, repair or replace entire unit

Differential pinion gear and

Axle noise on drive or

if conditions warrant.

ring gear out of adjustment

on coast only

or worn excessively

Tighten cap screws.

Loose axle shaft drive flange

Excessive backlash in

cap screws

axle driving

Reweld flange to shaft.

Flange loose on axle shaft

Replace drive flange and shaft

Worn splines on axle shaft

assembly.

at differential end

4-83

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |