|

|||

|

|

|||

|

Page Title:

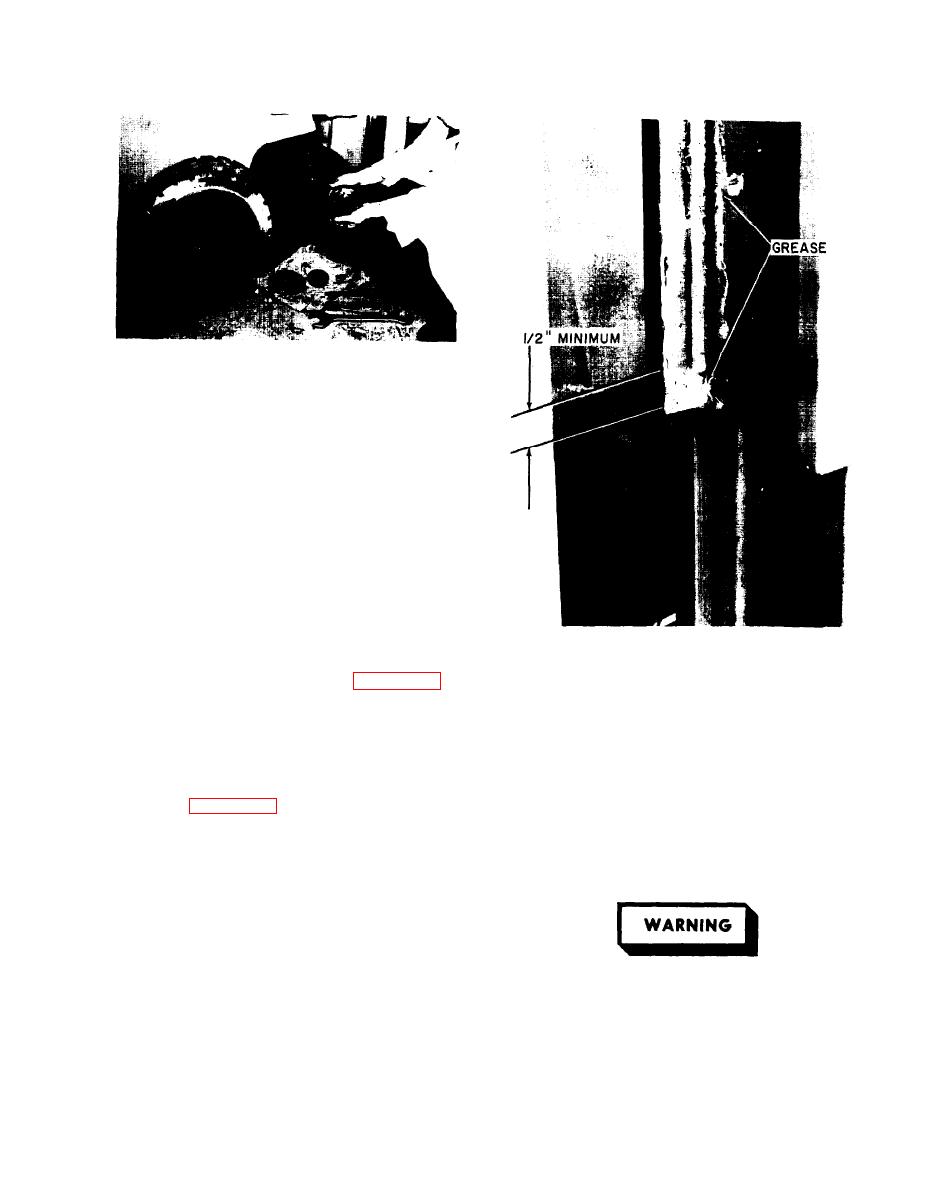

Figure 4-80. Repack Axle End Bearings |

|

||

| ||||||||||

|

|

Figure 4-80. Repack Axle End Bearings

d. Remove bearings and clean in a Stoddard type

cleaning solvent. Slosh bearings up and down in

s o l v e n t . Remove and tap large side of bearing

against a block of wood to dislodge solidified

particles of lubricant. Repeat operation until

bearings are thoroughly clean. Blow bearings dry

with compressed air. Direct air stream across

bearing to avoid spinning. Slowly rotate bearing by

hand to facilitate drying. Dip bearings in gear oil

and wrap them in clean paper until time of

installation.

e. Clean ring gear, pinion drive shaft, hub

Figure 4-81. Carriage Roller Travel Check

assembly, s p i n d l e a n d s p i n d l e s u p p o r t i n a

Stoddard type cleaning solvent. See figure 4-79 for

parts identification.

drift, leakage at packings, damage and security of

mountings. (Anchor pivot pins, flanges and

f. Inspect seal for cuts, scratches and nicks. It is

mounting rings.)

n e c e s s a r y to replace seal if such a condition is

found.

4-78. LIFT CHAINS. The lift chains are mounted

to the chain anchors on the lift carriage and at the

g. Refer to figure 4-80 and repack each axle end

c h a i n anchor rods near the lift cylinder piston

with specified lubricant. Each- axle end holds

head.

approximately 1 pound of grease. Check axle end

vent for obstruction, vent must be open.

a. If it becomes necessary to adjust the lift

chains, proceed as follows:

h. Install bearings, seal, hub, washer, spindle nut,

cotter pin and hub cap. Tilt upright back and

remove blocking.

4-76. UPRIGHT AND LIFT MECHANISM

Keep clear of load and carriage when

MAINTENANCE AND ADJUSTMENTS.

making adjustments to avoid injury if any

malfunction should occur and cause load or

4-77. LIFT AND TILT CYLINDERS. Check for

carriage to fall.

4-57

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |