|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

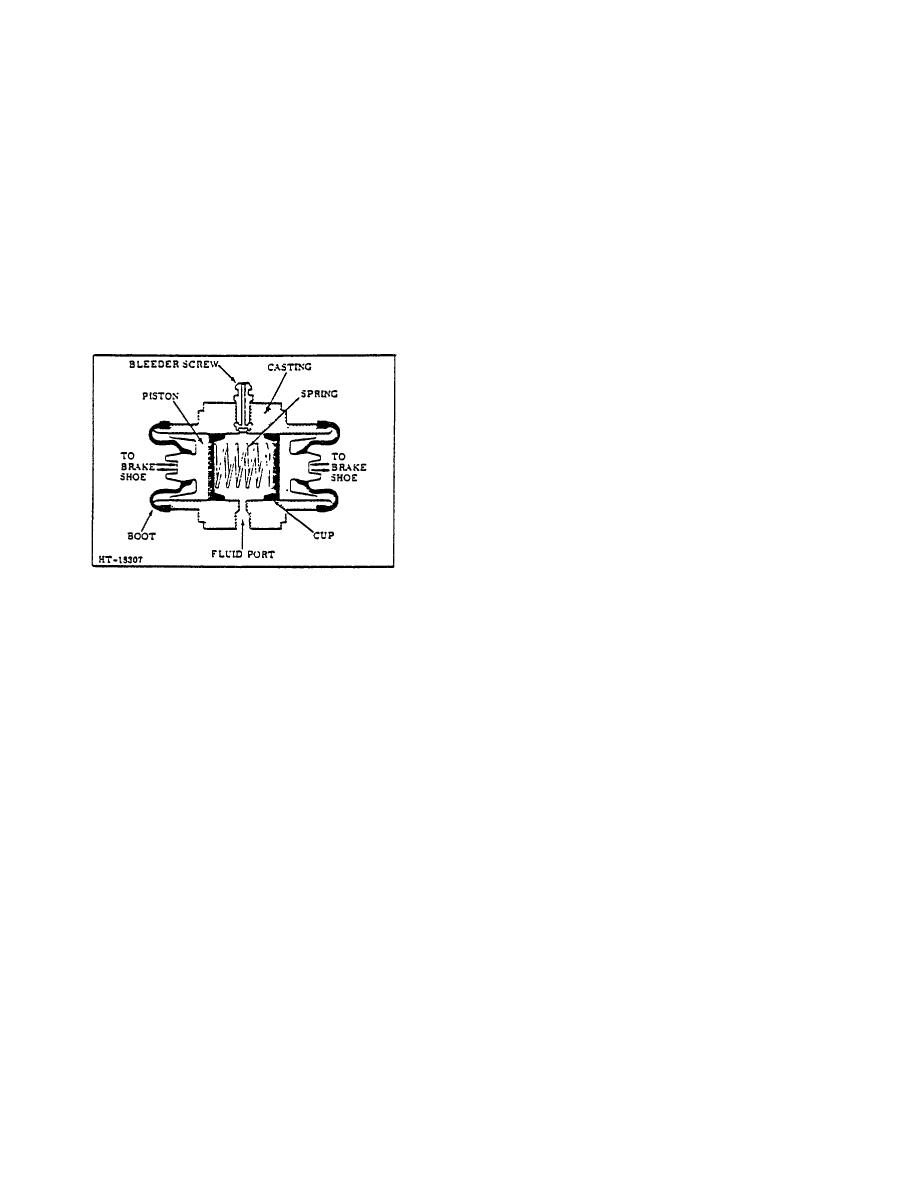

TOPIC 3. WHEEL CYLINDERS

2. Remove hydraulic line attached to wheel

A. DESCRIPTION

cylinder.

Remove wheel cylinder mounting

capscrews and remove cylinder.

The hydraulic wheel cylinder houses two opposed

pistons which actuate the opposed brake shoes. (See

3. Pull boots from cylinder and push out internal

Figure 9.) The pistons, rubber cups, and springs are held

parts. Low pressure air at fluid inlet can be used

in place, in the cylinders, by the brake shoe mechanical

to remove cylinder components.

pressure.

The opened ends of the cylinders are

4. Clean all parts thoroughly and keep them clean

protected with rubber boots. Since the wheel cylinders

until unit is ready for assembly. Use lint-free

of a hydraulic brake system are a very important part of

cloth for cleaning.

the whole system, It is necessary that the following

reconditioning instructions are carefully followed:

CAUTION

Wash parts thoroughly in denatured

alcohol or clean brake fluid. Never

use gasoline, kerosene, pant thinner

or other mineral base solvents as

they will damage rubber components.

5. Thoroughly inspect all parts for wear, corrosion

or other conditions which might impair cylinder

action.

6. if wheel cylinder is to be honed, follow specific

instructions furnished with honing equipment, as

these instructions may vary.

NOTE

Cylinder honed oversize will leak and

must be discarded.

Figure 9. Wheel Cylinder

7. Lubricate all parts and cylinder walls with clean

brake fluid. laser each piston in its respective

B. SERVICE

end. Never try to push piston through length of

cylinder After cylinder is assembled, install

1. Remove wheel assembly, bearings and brake

cylinder boots.

Be sure they are properly

shoes.

(Refer to DRIVE UNIT REMOVAL,

located in grooves provided.

.MAINTENANCE MANUAL.)

8. Reassemble cylinder to backing plate.

Install

brake unit and wheel assembly.

TOPIC 4. PARKING BRAKE

A. DESCRIPTION

B. HAND BRAKE ADJUSTMENT

A dual shoe mechanical brake, mounted at the drive

To compensate for brake lining wear the hand brake

shaft, is used as a parking brake. The brake shoes are

lever must be adjusted. Refer to HAND BRAKE LEVER

actuated through a cable by an adjustable over-center

ADJUSTMENT La BRAKE SYSTEM MAINTENANCE

type lever mounted on the left hand cowl panel.

MANUAL.

The brake mechanism requires no lubrication except at

C. BRAKE SHOE ADJUSTMENT

time of reassembly. Brake actuating mechanism, such

as hand lever and linkage, should be lubricated

If the adjusting knob on the parking brake handle will no

periodically.

longer provide correct brake adjustment and sufficient

brake lining is still available, further adjustment is made

at the lower brake-cable yoke.

3-153

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |