|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

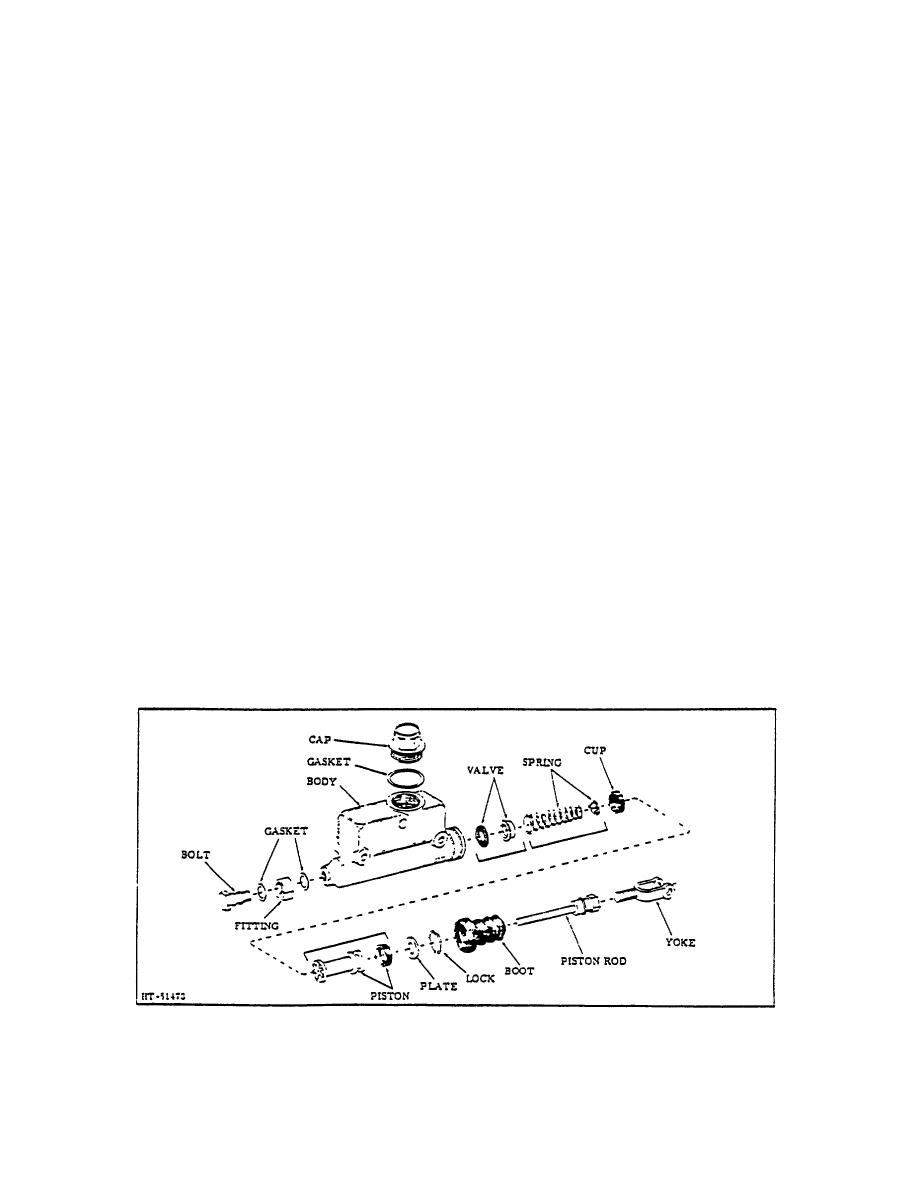

TOPIC 2. MASTER CYLINDER

A. DESCRIPTION

CAUTION

When lock ring is removed, entire

Brake cylinder and fluid reservoir are combined in one

piston assembly will spring out if not

casting and are joined by intake and by-pass ports

held in place.

located in the cylinder wall. Internal parts are removed

or installed at push rod end. Stop plate holding Internal

8. Carefully remove copper washer, piston, rubber,

parts is retained by a lockwire clipped into cylinder bore.

spring and seat.

Cylinder piston is operated through a push rod

connected to the brake pedal. The push rod and

9. Working from other end of cylinder, remove

cylinder opening Ls enclosed with a rubber boot.

outlet fitting bolt, copper washers, and brake line

fitting.

It is considered impractical to thoroughly clean the

cylinder and fluid reservoir mounted La the truck. For

10. Remove filler cap and all other washers and

this reason follow instructions below.

fittings.

B. REMOVAL

11. Clean hydraulic parts and keep clean so that

there is co trace of dirt, metal filings, sludge, or

1. Remove floor plate.

other deposits when unit is ready for assembly

Do not use cotton waste. Use lint-free cloth in

2. Disconnect brake hydraulic line attached to

cleaning. Internal parts must be cleaned in

master cylinder.

clean denatured alcohol or hydraulic brake fluid.

3. Remove clevis pin securing push rod to brake

CAUTION

pedal assembly.

Mineral base cleaning solvents

(gasoline,

kerosene,

distillates,

4. Remove capscrews holding master cylinder to

carbon tetrachloride, acetone, paint

inside of frame and remove cylinder.

thinners, etc.) deteriorate rubber

parts, causing them to

5. Secure cylinder in vise exercising care so as not

become soft, tacky and swollen.

to distort cylinder or crack the casting.

6. Remove boot and push rod.

Cylinder castings may be cleaned with

usual cleaning methods but must be finish

7. Pry out lock ring holding piston assembly in

cleaned with denatured alcohol or brake

position.

fluid to remove all traces of solvent.

Figure 7. Master Cylinder Assembly

3-151

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |