|

|||

|

|

|||

|

Page Title:

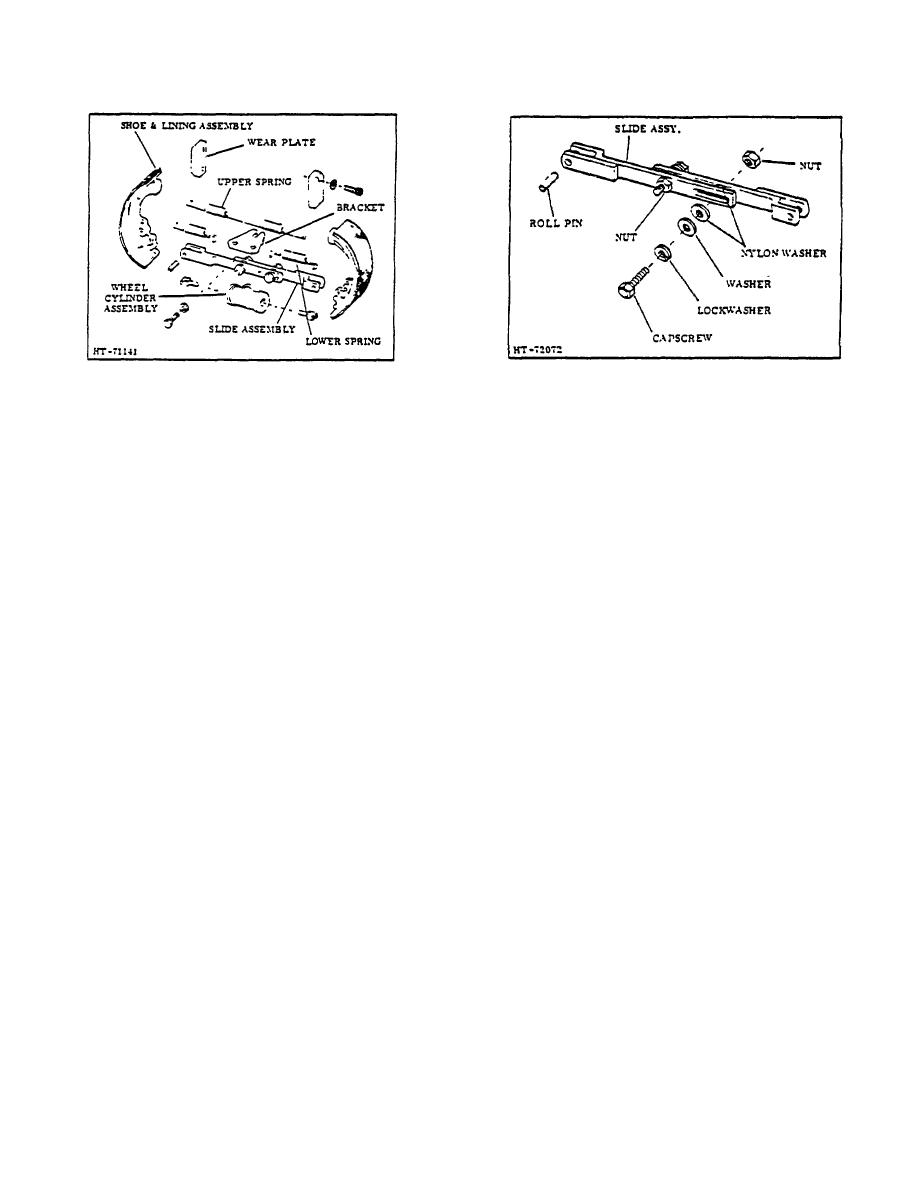

Figure 5. Self-Adjusting Brakes (Exploded View) |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Figure 5. Self-Adjusting Brakes (Exploded View)

Figure 6. Brake Self-Adjuster

1. Remove upper and lower shoe return springs.

4. Clean inside of backing plate, brake drum and

other parts to be assembled.

2. Remove brake shoes and adjuster Link as an

assembly.

5. Check wheel cylinders for leakage, even if

cylinder appears to be in good condition. The

3. Drive out roll pins which attach adjuster link to

best practice is to overhaul wheel cylinders

brake shoes. Compress adjuster link by placing

when new brake shoes are installed.

one end on a solid surface and tapping other

end with a wooden mallet or a block of wood

6. Place shoe and link assembly in a place and

until fully compressed.

install springs. Install wheel assembly in direct

reversal of removal procedure. While turning

F. INSTALLATION

wheel SLX times in each direction, torque

retaining out to a maximum of 50 ft. lbs., then

To install shoes with new ling, proceed as follows:

back nut off 30' minimum -60 maximum to allow

cotter pin installation.

1. If

self-adjusted

link

is

inadvertently

disassembled, it must be reassembled exactly

7. The first time brake pedal is depressed after

as originally constructed (Figure 6). Torque

installing new shoes automatically sets the

capscrews to 14 16 inch lbs., and lock outs to 29

adjustment.

inch lbs. Slip resistance must be from 250 to

300 lbs. and link should be fully retracted when

Drive wheels should be removed periodically

assembly is completed.

until approximate wear period for brake lining

can be determined. No further adjustment is

2. Attach adjuster link to brake shoes with roll pins.

required after shoes are replaced.

3. Make certain backing plate is secured tightly to

CAUTION

axle, also that it is nor sprung or damaged.

NEVER apply pressure to brake pedal

until drive wheel brakes and wheels

are completely assembled.

3-150

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |