|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

i. Ensure that bearings have been properly

packed with grease, then tighten locknut

so there is a slight drag on the bearings.

Lock the nut m position by bending prongs

of lockwasher over.

j. To reinstall the jackshaft. place in position

in the drive housing. Then, using a soft

mallet, drive the shaft in place, and at the

same time align the holes in the retaining

cap with the holes in housing. Install and

tighten capscrews.

k. Replace wheel.

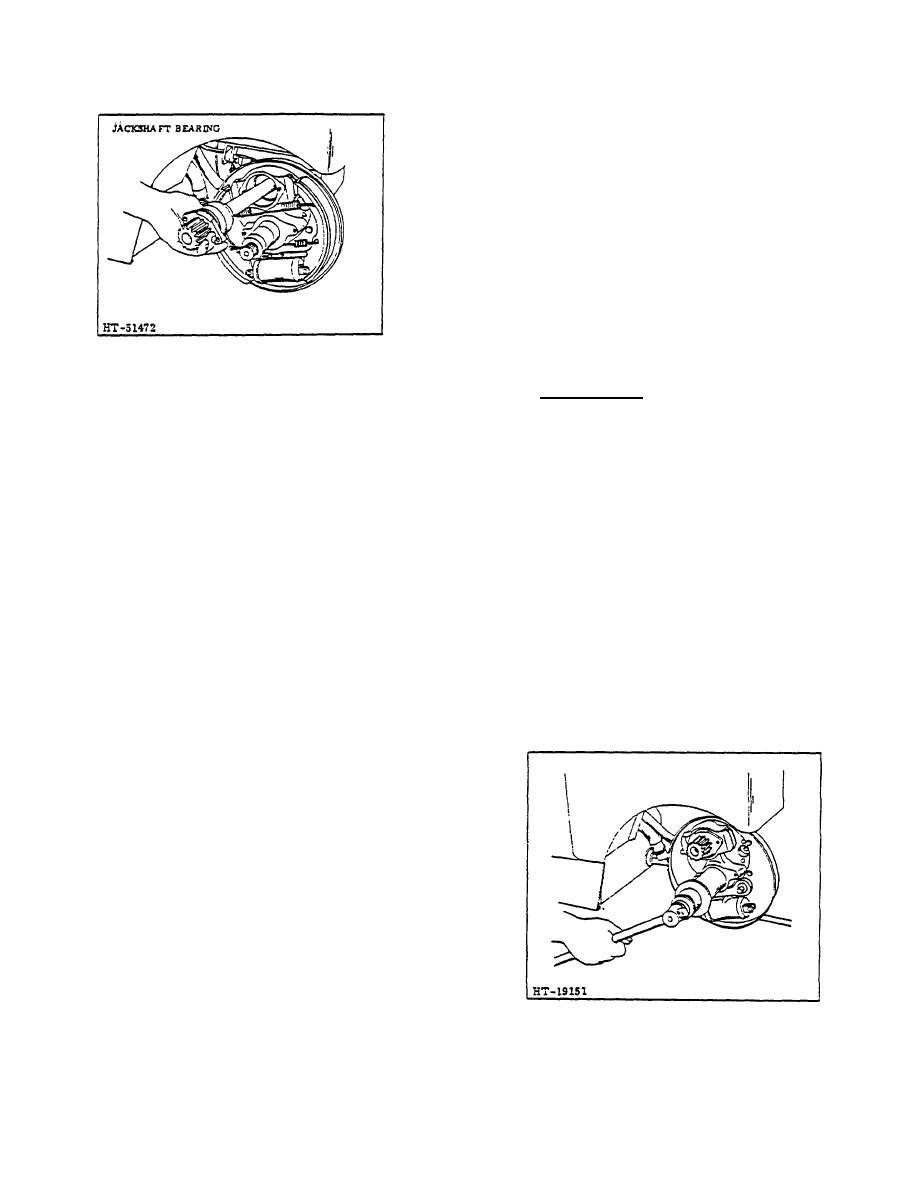

Figure 12. Jackshaft Removed

4. Spindle Service

c. Install a weight puller in the threaded end

of the jackshaft and exercising care,

To remove the drive wheel spindle, proceed

remove the shaft.

as follows:

NOTE

a. Remove

wheel.

(See

WHEEL

The

bearing

assembly

will-be

REMOVAL).

removed with the jackshaft.

Figure

12.

b. Remove dust cover.

d. Straighten the locking prongs of the

c. Remove the cotter pin.

Locknut and

lockwasher (Figure 10) and remove

washer from the spindle at the back side

locknut lockwasher.

of the drive housing.

e. Place the shaft in a suitable press and

d. Install a spindle puller as shown in Figure

force the bearings from the shaft.

13 and remove the spindle.

CAUTION

e. Carefully inspect the spindle for any

Exercise care to prevent damaging

evidence of uneven wear or damage.

the axle shaft cap.

Replace If worn. chipped or bent.

f. After bearings and bearing cup are

removed, slide the retainer cap from the

shaft.

NOTE

Whenever the jackshaft is removed, It

is recommended that the oil seals be

replaced.

g. Clean and inspect all parts and replace

where necessary.

h. To reassemble the jackshaft components.

slide the retainer ring and new seal on

shaft. Next, replace the bearings and

bearing cup, washer, lockwasher and

locknut.

Figure 13. Removing Spindle

3-140

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |