|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

The following procedure is recommended to

(8) Release press and remove tires. Inspect

replace cushion tires.

new tire and wheel assembly.

(1) Remove wheel and tire assembly from lift

(9) Install wheel and tire assembly on lift

truck.

truck.

(2) Check Inside diameter of new tire.

Remove any signs of scale or rust with

3. Jackshaft Service

sandpaper. Lubricate inside of new tire

with bearing grease.

(3) Place a circular ram on the press table.

The length of the ram must be greater

than the width of the tire to allow complete

removal of the old tire.

The outside

diameter of the ram must be large enough

to rest squarely on the bull gear's flat

surface .

(4) If the outside edge of the wheel is not

flush with the edge of the metal insert in

the old tire, measure how far wheel is

recessed Inside the tire. New tires must

be replaced to the same position as the

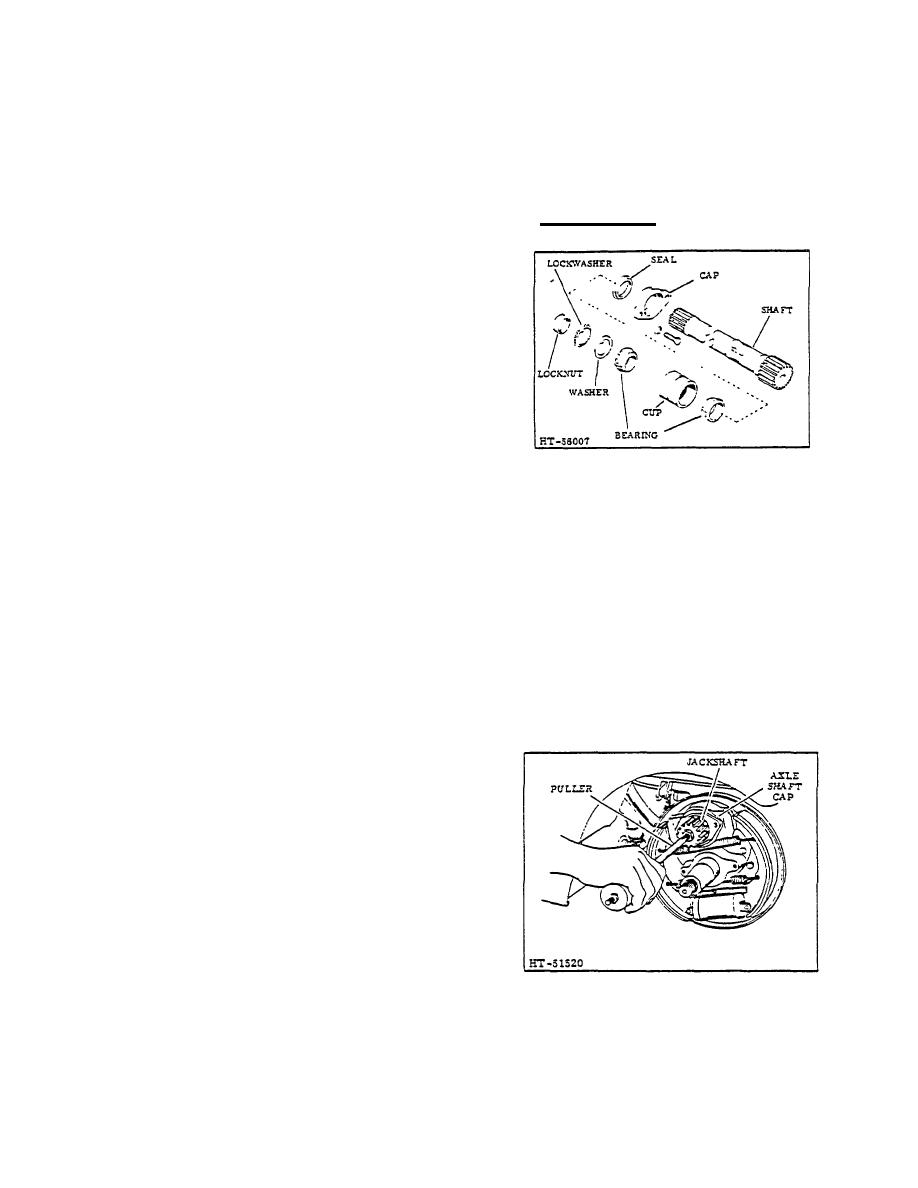

Figure 10. Jackshaft Assembly

worn tire was installed on the wheel. A

spacer, slightly smaller in diameter than

The jackshaft is the connection between the

the inside diameter of the tire and the

differential assembly (first reduction) and the bull

same thickness as the depth of the

recess, can be used to obtain the proper

gear in the drive wheel (second reduction). The

amount of recess.

jackshaft is supported by two opposed, tapered

roller bearings; its splined end fits into the differential

(5) Center worn tire and wheel assembly over

and the opposite pinion end drives the wheel

ram. be sure ram and wheel "mate-up"

through the bull gear. To remove the Jackshaft,

squarely.

proceed as follows:

(6) Position new tire on top of wheel and tire

assembly. Align new tire and wheel and

a. Remove wheel. (See WHEEL REMOVAL.)

tire assembly to be concentric with each

other. Make certain the outside of the

b. Remove capscrews which secure the jackshaft

wheel is positioned upwards, because the

dust shield.

outside edge of the wheel has a slight

chamfer to help guide the wheel into the

new tire.

NOTE

The tire can only be installed in one

direction without risking damage to

the wheel.

(7) Start pressing new tire onto wheel and

worn tire off the wheel. Run press slowly

for the first Inches of travel because this is

the critical stage of pressing wheel into

tire. If tire begins co cock, stop press and

realign wheel and tires, a sharp jar with a

mallet will normally realign wheel and tire.

If the wheel is to be recessed in the tire.

stop hydraulic press after the wheel has

been started into the new tire and position

Figure 11. Pulling Jackshaft

the spacer on the inside diameter of the

new tire. The spacer must rest squarely

on the outer edge of the wheel. Continue

pressing new tire onto wheel until tire is

correctly positioned on wheel.

3-139

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |