|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

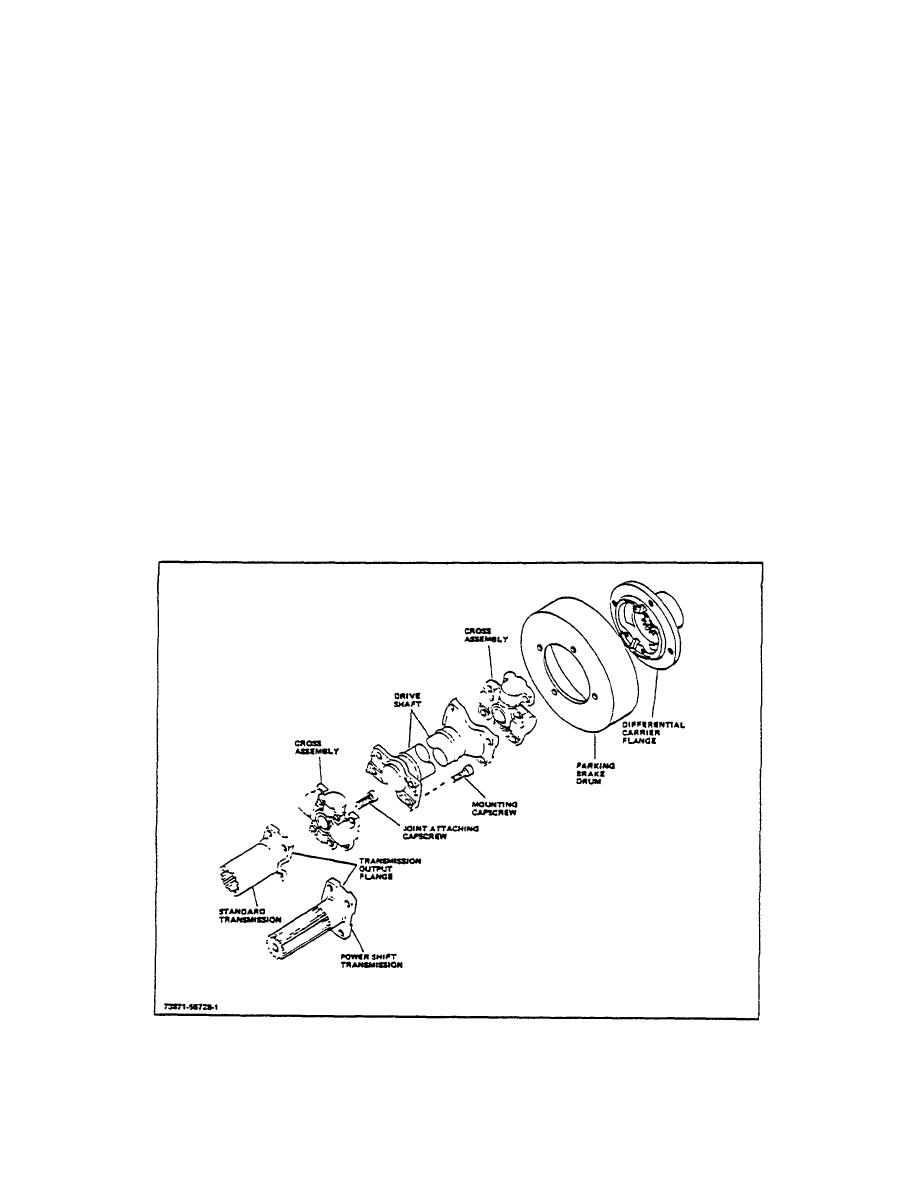

TOPIC 1. UNIVERSAL JOINT

A. GENERAL

to gain access to the universal Joint assembly.

The purpose of the universal joint assembly is to transfer

2. At the transmission end of the assembly,

the transmission output power to the drive wheels of the

remove the capscrews that attach the cross

truck. The universal joint assembly is the heavy duty

assembly to the output flange.

industrial type which consists of a drive shaft or center

plate, too cross assemblies, a transmission output

3. At the differential end of the assembly, remove

flange, and the necessary hardware.

the capscrews that attach the cross assembly to

the differential carrier flange.

Very little service is required for the universal joint

assembly, other than periodic lubrication of the cross

4. Remove the entire universal Joint assembly

assembly bearings. Also, it is recommended that the

from the lift truck.

torque of capscrews be checked every 100 hours of

operation. The mounting capscrews that secure the

5. Remove the output flange from the transmission.

cross assemblies to the drive shaft or center plate, and

the joint attaching capscrews must be tightened to

C. DISASSEMBLY - INSPECTION

specified torque of 25-30 lb-ft CRY THREADS, or 20-24

lb-ft LUBRICATED THREADS.

1. Remove the mounting capscrews and remove

the cross assemblies from the drive shaft or the

B. REMOVAL

center plate (depending upon the length of the

universal joint assembly).

1. Raise and securely block the lift truck

Figure 1-1. Universal Joint Assembly (Typical)

3-131

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |