|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

cracking, external damage or damage from

2. Install a new seal in the pump body. When

pressing, or other defects which might impair

installing the seal make certain it is square with

efficient operation.

the seal bore and is firmly seated.

2. Check the bearing and shaft assembly by

3. Place the pump housing in an arbor press on a

rotating the bearing. If movement is rough or

suitable support and press the shaft and bearing

the bearing is binding or running dry from lack of

assembly into the bearing bore until the bearing

lubricant, the shaft and bearing assembly must

is firmly seated against the inside housing

be replaced.

shoulder.

CAUTION

NOTE

Do not wash the bearing assembly as

Care must be taken during this

it is permanently lubricated at the

operation to prevent damage to the

factory.

seal.

3. Inspect the face of the impeller hub, where it

4. Install the retainer rings in the front and rear of

contacts the seal, for any scoring or pitting. The

the bearing.

face must be smooth so as not to damage the

seal.

5. Using an arbor press, install the impeller on the

pump shaft until the impeller is flush with the end

4. Check the impeller seal for a smooth, flat

of the shaft. Revolve the impeller to make

surface. A light film of lubricant applied to the

certain that it is free to turn and firmly seated on

face of the seal facilitates seating and sealing.

the seal.

5. Always use a

new

pump

gasket

when

NOTE

reassembling.

If the impeller is properly seated on

the seal, a slight drag caused by the

mating faces of the seal assembly

and the impeller will be felt.

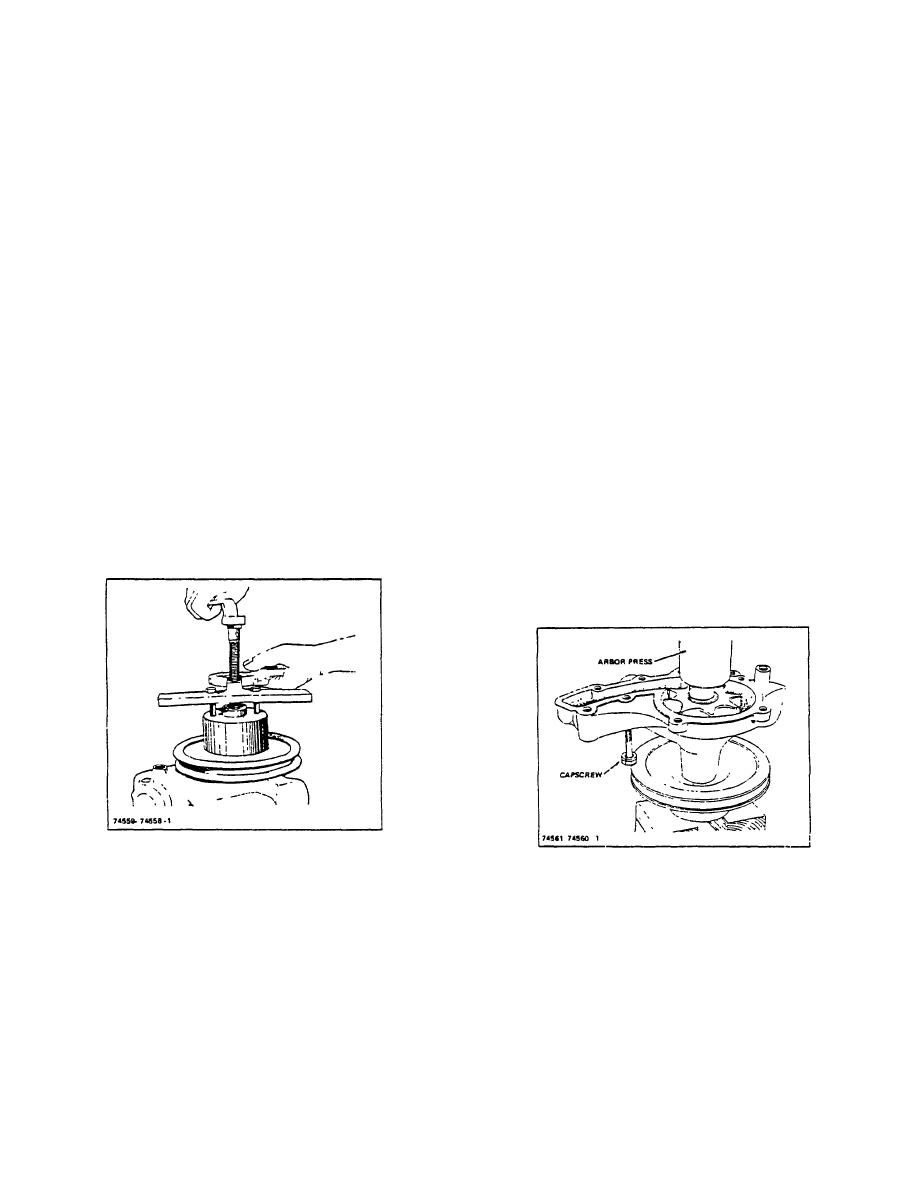

Figure 2-3. Removing Water Pump Pulley

Figure 2-4. Water Pump Assembly Showing Inserted

F. ASSEMBLY

Capscrew, Prior to Pulley Press Fit.

Reassemble the water pump by referring to Figure 2-1

G. INSTALLATION

for the relative location of the parts, and reversing the

sequence of the disassembly procedure as follows.

1. Measure pulley and shaft.

Recommended

minimum press fit is .001".

(Pulley must fit

1. When the bearing and shaft assembly is

snugly on shaft).

installed, use thick soap suds on the assembly

and the impeller seal to prevent damage to the

2. Insert capscrew in pump body BEFORE cross-

seal.

ing pulley on to shaft (Figure 2-4). Coat

R-155-1

3-107

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |