|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

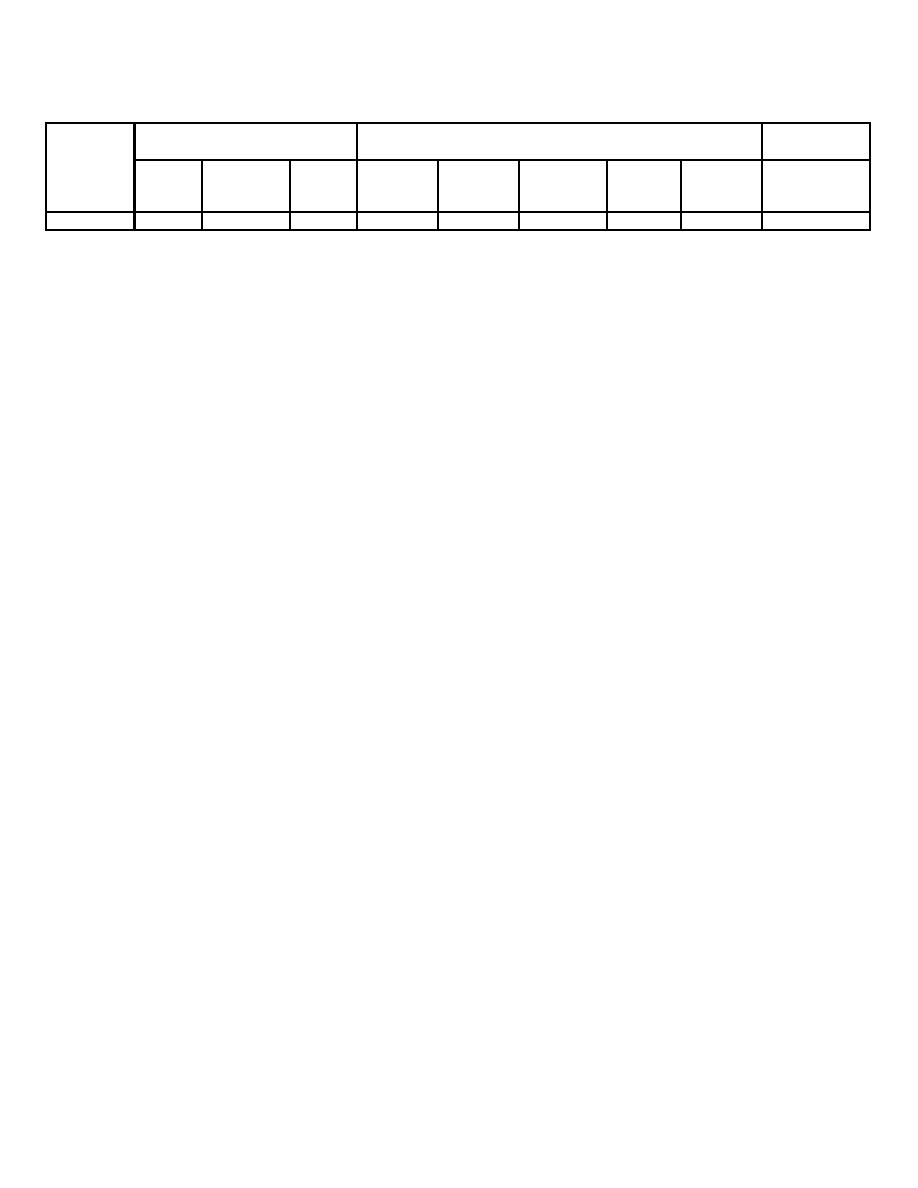

TM 10-3930-644-14 & P

ALTERNATOR SPECIFICATIONS

Field Current

Cold Output

at Specified Voltage

(80F.)

Rotation

Rated

Viewing

Spec.

Approx.

Approx.

Hot Output

D.E.

Grd.

Amps.

Volts

Volts

Amps.

RPM

Amps.

RPM

(Amps.)

CW

Neg.

4.0 - 4.5

12

*

22

2000

33

5000

37

*Voltmeter not needed for cold output check. Load battery with carbon pile to obtain maximum output.

the voltage by the current given in alternator

specifications. Remember that the wind

CAUTION

ing resistance and ammeter readings will vary

Use pressure sensitive tape, and not

slightly with winding temperature changes. If the

friction tape which would leave a

rotor is not defective, but the generator fails to

gunny deposit on the shaft.

supply rated output, the defect is in the diode

To remove the drive end frame from the rotor,

trio, rectifier bridge, or stator.

Place the rotor in a vise and tighten only enough

3. Diode Trio Check The diode trio is identified in

to permit removal of the shaft nut.

Figure 2-6. First, connect an ohmmeter, using

lowest range scale, from diode trio long

connector to end frame as shown in Step 2,

CAUTION:

Figure 2-6; then, reverse lead connections. If

Avoid excessive vise tightening as

both readings are the same, check for grounded

this may cause distortion of the rotor.

brush lead clip caused by omission of insulating

1. Remove the shaft nut, washer, Pulley, fan, and

washer (Fig. 2-6), omission of insulating sleeve

the collar, and then separate the drive end frame

over screw, or damaged insulating sleeve.

from the rotor shaft.

Remove screw to inspect sleeve.

If screw

2. Rotor Field Winding Checks

assembly is correct, and both ohmmeter

readings are the same, replace regulator.

To check for opens, connect the test lamp or

ohmmeter to each slip ring.

To check the diode trio, remove it from the end

frame assembly by detaching the three nuts, the

If the lamp fails to light, or if the ohmmeter

attaching screw, and removing the stator

reading is high (infinite), the winding is open

assembly. Note that the insulating washer on

(Fig. 2-5).

the screw is assembled over the top of the diode

trio connector. Use the lowest range of an

Connect test lamp or ohmmeter from one slip

ohmmeter having a 1-1/2 volt cell. Connect the

ring to shaft. If lamp lights, or if reading is low,

ohmmeter to the single connector and to one of

the rotor winding is grounded (not illustrated).

the three connectors (Figure 2-8). Observe the

reading. Then, reverse the ohmmeter leads to

The winding is checked for short-circuits or

the same two connectors. If both readings are

excessive resistance by connecting a battery

the same, replace the diode trio. A good diode

and ammeter in series with the edges of the two

trio will give one high and one low reading.

slip rings. Note the ammeter reading and refer

Repeat this Same test between the single

to alternator specifications. As ammeter reading

connector and each of the other two connectors.

above the specified value indicates shorted

Also, connect the ohmmeter to each pair of the

windings; a reading below the specified value

three connectors (not illustrated). If any reading

indicates excessive resistance.

is zero, replace the diode trio.

An alternate method is to check the resistance

NOTE

of the field by connecting an ohmmeter to the

Figures 2-6 and 2-8 illustrate two

two slip rings (Fig. 2-5).

If the resistance

diode trios differing in appearance.

reading is below the specified value, the winding

Either one of these diode trios may

is shorted; if above the specified value the

be used in the alternator, since the

winding has excessive resistance. The specified

two are completely interchangeable.

resistance value can be determined by dividing

R-146-1

3-86

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |