|

|||

|

|

|||

|

Page Title:

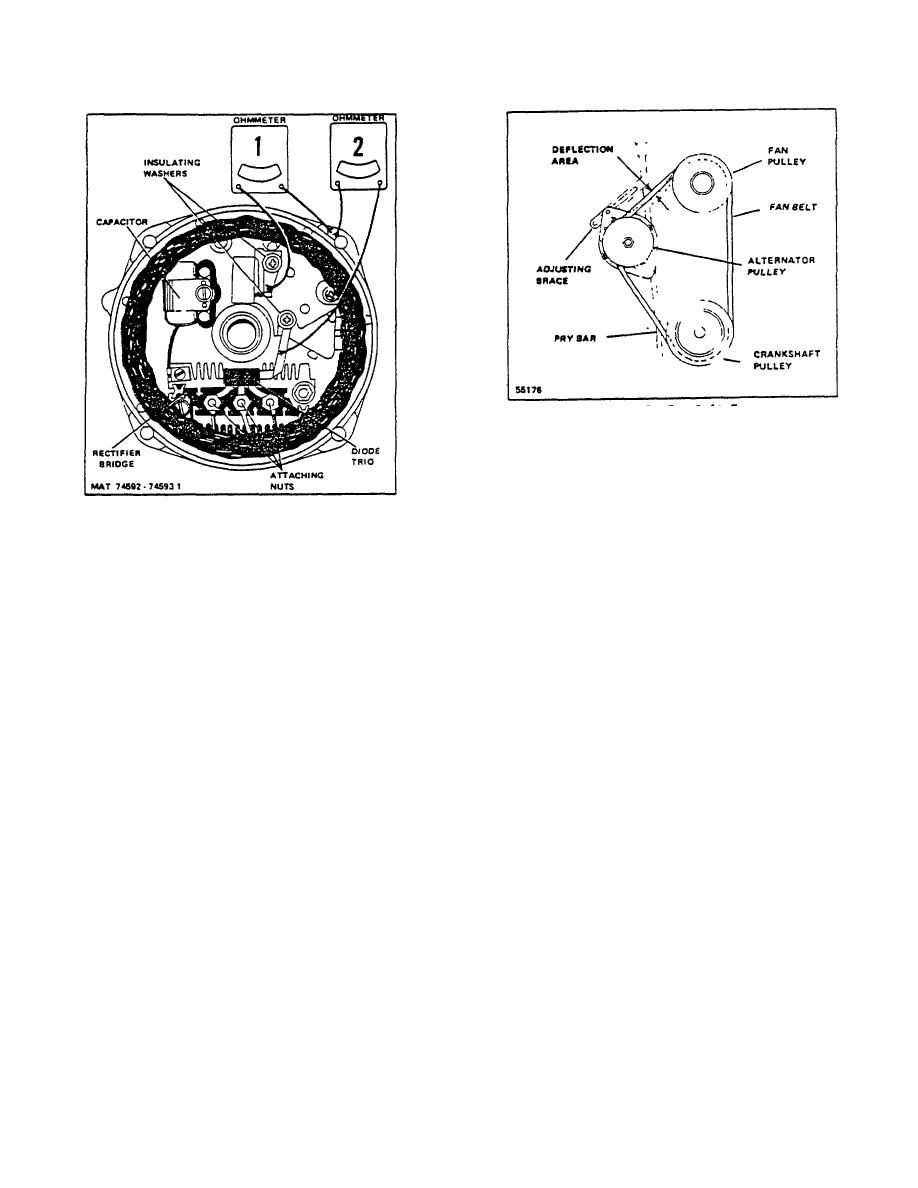

Figure 2-6. End Frame Assembly, Inside View |

|

||

| ||||||||||

|

|

TM 10-3930-644-14 & P

Figure 2-7. Fan Belt Tension

1. Disconnect the battery from the electrical circuit

prior to alternator removal/installation.

2. Disconnect and properly label the "BAT"

Figure 2-6. End Frame Assembly, Inside View

(Battery), No. I and No. 2 terminal leads at the

alternator.

D. ADJUSTMENT

3. Loosen the adjusting brace and the pivot

Be sure to check the mounting bolts for tightness and

mounting bolt, then push alternator towards

the belt for alignment, correct tension and wear. Belt

engine until fan belt is disengaged from the

tension should be adjusted to allow approximately .375"

alternator pulley.

inward deflection of the belt between the alternator

pulley and the fan pulley with a force of about 10

4. Carefully remove the alternator from the engine

pounds. (See Figure 2-7)

as the pivot mounting bolt and adjusting brace

capscrew are removed.

When tightening belt tension always apply pressure

against the stator laminations, never against the end

F. SERVICE

frames. Inspect the brush springs and brushes for

evidence of any damage, wear or corrosion. Replace

Proceed according to the following sequence.

any brush springs or brushes in doubtful condition.

1. Disassembly

A noisy alternator can be caused by worn or dirty

bearings, loose mounting bolts, a loose drive pulley, a

To disassemble the alternator, take out the four

defective diode or a defective stator.

thru-bolts, and separate the drive end frame and

rotor assembly from the stator assembly by

E. REMOVAL

prying apart with a screwdriver at the stator slot.

A scribe mark will help locate the parts in the

Alternator: After extensive periods of operation or during

same position during assembly.

major engine overhaul, the alternator should be removed

from the truck for a thorough inspection and cleaning of

After disassembly, place a piece of tape over the

all parts.

The alternator consists of four main

slip ring end frame bearing to prevent entry of

components which includes the two end frames, the

dirt and other foreign material, and also place a

stator and the rotor. The following procedures should be

piece of tape over the shaft on the slip ring end.

used for proper removal:

If brushes are to be reused, clean with a soft dry

cloth.

R-146-1

3-85

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |