|

|||

|

|

|||

|

Page Title:

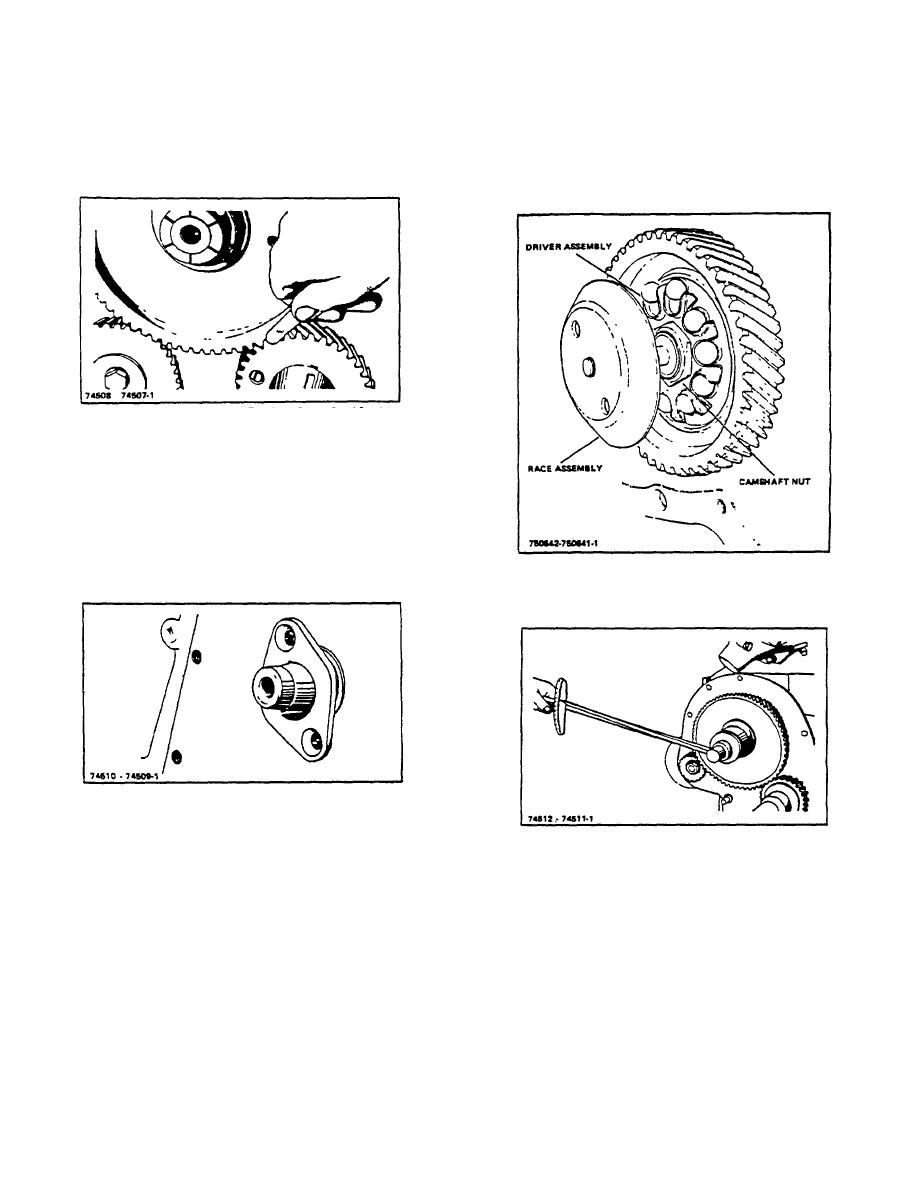

Figure 10-3. Checking Timing Gear Backlash (Typical) |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Gears fitted with excessive backlash usually chatter at

3. On F163 engines, install the driver assembly

idling speeds while gears too tightly fitted will howl or

(Figure 10-5) and camshaft nut.

On F135

whine. It is better for gears to be slightly loose than to

engines install the camshaft gear nut only.

ride hard.

Tighten camshaft gear nut to a torque of 175-

180 lb. ft. (Figure 10-6).

Figure 10-3. Checking Timing Gear Backlash (Typical)

Gears marked same as the original as far as sizes are

concerned should be used as replacements.

Carefully examine the camshaft thrust plate (Figure 10-4)

for scoring and wear and if any indication of either shows,

a new thrust plate should be assembled without question.

Refer to TOPIC 9 to check end play.

Figure 10-5. Camshaft Gear Nut Installation (F163

Engine)

Figure 10-4. Camshaft Thrust Plate

D. INSTALLATION

Figure 10-6. Torquing Cam Gear Nut (Typical)

1. Refer to sections covering crankshaft, camshaft,

4. Check camshaft end play as shown in Figure

governor and engine removal and installation.

10-7.

Refer to TOPIC 1.

FITS AND

TOLERANCES

section

for

the

correct

2. Assemble the cam gear to the camshaft by

dimension.

driving or pressing it on, at the same time

holding the camshaft forward with a suitable bar

CAUTION

through the fuel pump opening in the block so

NEVER USE THE CAMSHAFT NUT TO

there is no possibility of the camshaft bumping

PULL

THE

GEAR

ONTO

THE

the expansion plug at the rear end and forcing it

CAMSHAFT.

This will damage

out of position, thus causing an oil leak.

threads of the steel camshaft.

R-104-1

3-36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |