|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 10. GEAR TRAIN

A. DESCRIPTION

F135 Engine

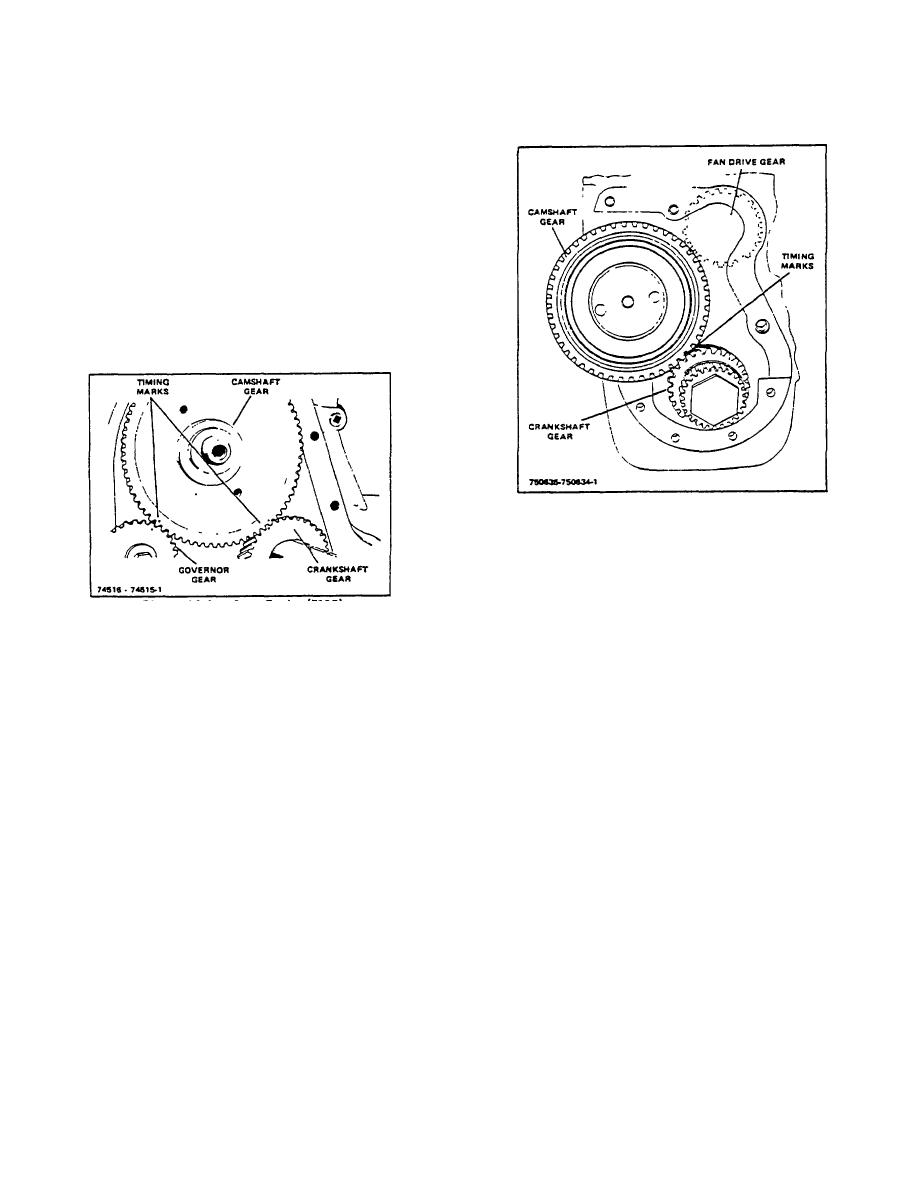

The gear train (Figure 10-1) consists of the crankshaft

gear, camshaft gear, and the governor gear.

The

crankshaft gear drives the camshaft gear, which, in turn,

drives the governor gear.

Correct timing sequence of the gear train is critical to

proper engine operation; it is accomplished by meshing

the camshaft drive gear and governor drive gear timing

marks, with their respective timing marks on the

crankshaft timing gear.

Figure 10-2. Gear Train (F163)

to replace all the gears when one or more are worn

badly enough to require replacement; however, such

drive train replacement is not recommended as a field

procedure because of the need for selecting gears with

Figure 10-1. Gear Train (F135)

the proper running clearance.

F163 Engine

Replacement crankshaft and camshaft gears are

The gear train (Figure 10-2) consists of the crankshaft

furnished in standard size, under size, and over size.

gear, camshaft gear and fan drive gear. The crankshaft

Gears marked "S" are standard; if they are marked "U"

gear drives the camshaft gear, which in turn drives the

with the number 1, 2, or 3, it signifies .001", .002", or

fan drive gear.

.003" under size. Similarly, oversize gears are marked

"0" with the number 1., 2, or 3.

The governor drive assembly is attached to the camshaft

by the camshaft gear nut. A governor race assembly is

NOTE

attached to the camshaft. Correct timing sequence of

A standard crankshaft gear with a

the gear train is critical to proper engine operation. It is

.002" oversize cam gear on the

accomplished by meshing the camshaft drive gear and

engine, could be replaced with a

crankshaft gear timing marks. The fan drive gear has no

.001" crank gear and a .001" oversize

timing marks and has only to be meshed with the

cam gear, or any other combination

camshaft gear when installed.

that

gives

a

.002"

oversize

dimension.

B. REMOVAL

Refer to respective sections for crankshaft, camshaft

C. INSPECTION

and governor removal and installation. Also see TOPIC

Timing gears and timing gear fits must be checked

17. ENGINE REMOVAL/ INSTALLATION.

carefully. To check the fit, use a screw driver to force

the mating teeth as far apart as possible and check this

The crankshaft, camshaft and governor and/or fan drive

clearance with feeler gauge (Figure 10-3).

If this

gears should be thoroughly cleaned and inspected for

clearance is .002" or greater, or if the gear teeth are

cracked or chipped teeth before reassembly. It is

badly scuffed and worn, the gear must be replaced.

generally desirable

Timing gears must be replaced in pairs.

R-104-1

3-35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |