|

|||

|

|

|||

|

Page Title:

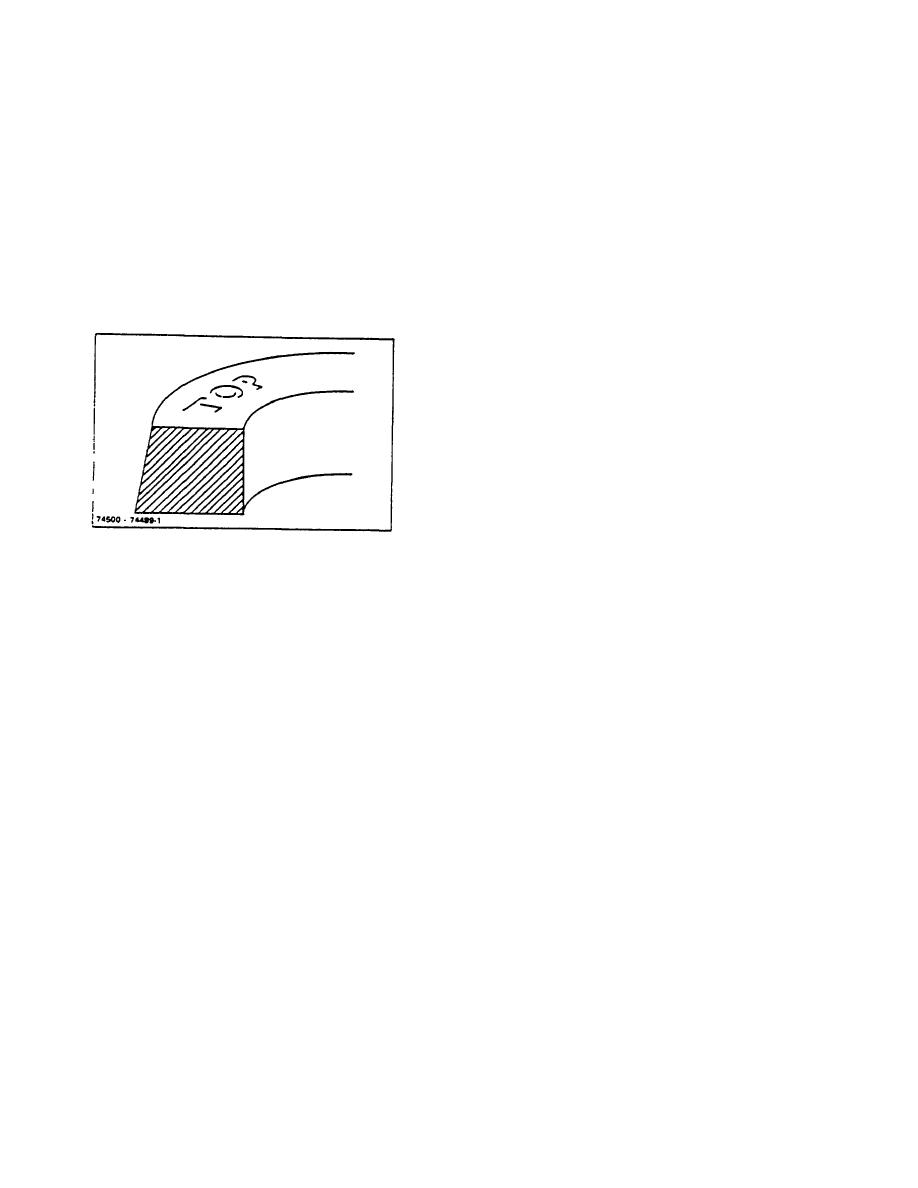

Figure 8-11. Install Tapered Rings with "Too" Side Up |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

5. Pin milled application install gap of expander

Secure connecting rod to crankshaft, replace rod bearing

cap and capscrews and torque to 40-45 lb. ft.

spacer 90 from pin, with hump of expander over

pin and ends butted. Install top segment, then

When pistons are ready for installation in the cylinders,

bottom segment with gaps of segments over pin.

compress rings carefully using a good ring compressor.

A light tap on the head of the piston will allow the

To install the balance of the rings, use a ring tool with

assembly to go into the cylinder very easily. If any

recess side up and place the ring in with the bottom side

difficulty in tapping piston and ring assembly into the

up. Start with the lowest ring first.

cylinder is encountered, the compressor should be

removed and rings checked for correct installation in the

Some piston rings are taper faced. These are clearly

groove.

marked "TOP" on the side to be up when assembled on

piston (Figure 8-11).

Measure the running clearance between piston and

cylinder bore as described in preceding paragraph E.

Piston and Piston Ring Inspection. The clearance is

critical and should be accurate. Pistons are available for

redimensioned cylinder bores in .020", .030", .040" and

.060" oversizes.

Hold the feeler stock along the side of the cylinder bore

at bottom of crankcase. With rod connected insert the

piston into the cylinder bore in running position. With the

correct clearance between the piston and cylinder bore,

the .003" feeler gauge can be with drawn with a slight

pull. The pull should not exceed 5 to 10 pounds. Test

the clearance at the end of the piston pin and at points

90 from the ends of the pin.

Figure 8-11. Install Tapered Rings with "Too" Side Up

When fitting a piston to a new or accurately resized bore,

Position ring in the tool so the expanding fingers will fully

the bore inner diameter should be the same at top and

engage both ends.

bottom. Therefore, the clearance may be taken at either

end. In bores that have been worn, but not resized,

Apply pressure on handles so ring is completely

some taper giving extra clearance at the top of the bore

expanded. Pass the expanded ring and tool recessed

is likely. In such cases, the clearance must be checked

side down over the piston to the proper groove.

at the bottom of the bore where the wear is least and the

fit is closest.

CAUTION

NOTE

If piston is equipped with a steel

Although the connecting rod bearing

groove insert, this insert must be

side clearance is less critical than the

installed on top of the number one

bearing running clearances, no

ring. (The steel groove insert is not

bearing should be assembled without

part of the re-ring kit, and can be re-

checking the side clearance.

used when replacing rings.)

Check the side play of the rods by forcing the connecting

I. INSTALLATION

rod fully to one side or the other. Insert a feeler gauge

between the crankshaft and bearing edge. The desired

Oil all rings and pistons before installing them in the

side play is from .0100" to .0060". If the clearance is

cylinder bore.

excessive, the rod must be replaced. If there is no side

Replace pistons in the same manner as they are

play, the piston and connecting rod must be removed

removed, through the top of the cylinder bore. Care

and checked to determine cause of binding.

should be taken to keep the piston rings properly seated

and staggered during insertion.

Reinstall oil pan gasket and oil pan. (Refer to TOPIC 15.

OIL PAN,)

NOTE

Ensure that pistons, connecting rods

Reinstall engine.

(Refer to TOPIC 17.

ENGINE

and rod caps are all replaced in their

REMOVAL/INSTALLATION.)

respective cylinder locations as

removed.

R-104-1

3-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |