|

|||

|

|

|||

|

Page Title:

TOPIC 9. CAMSHAFT, CAMSHAFT BEARINGS, AND VALVE TAPPETS |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 9. CAMSHAFT, CAMSHAFT BEARINGS, AND VALVE TAPPETS

A. REMOVAL

9. If wear is found to be in the bushings instead,

these must be replaced using precision service

bushings, available for that purpose, which

1. Refer to TOPIC 17 for engine removal. Refer to

require no reaming, only care In assembly, to

TOPIC 18 or 19 for governor removal and

line up oil holes, and not damage the bushings

camshaft access. Remove camshaft gear nut.

as they are being pressed in.

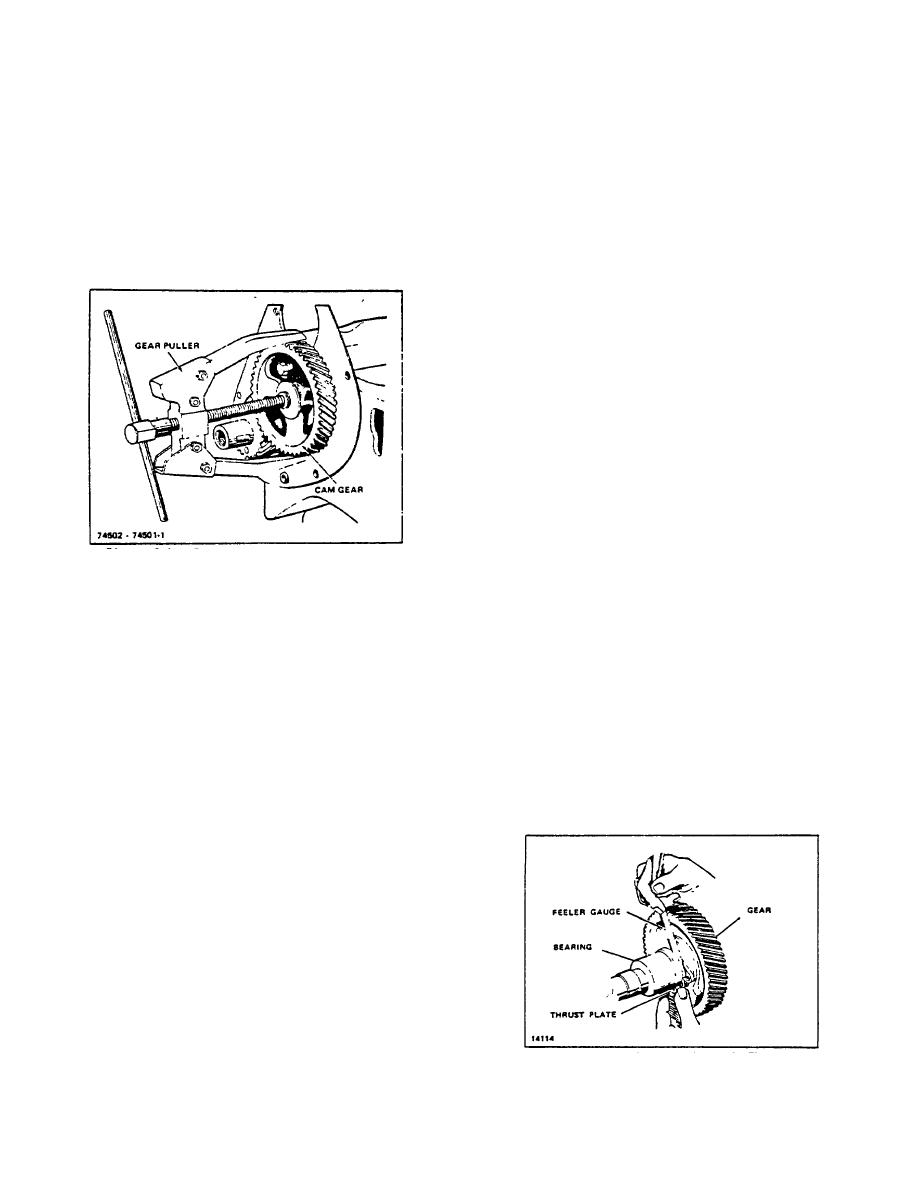

2. Using a Duller, remove the cam and crank gears

(Figure 9-1).

CAUTION

When installing camshaft use special

care to prevent camshaft bumping,

and loosening expansion plug which

cause an oil leak.

B. INSPECTION

1. Checking Camshaft End Play Camshaft end

play is controlled by the thrust plate. The actual

distance which the shaft may move forward or

rearward depends upon the distance between

the rear face of the gear and the front face of the

cam journal, minus the thickness of the thrust

plate. Thus, when a condition of excessive

camshaft end clearance s; found, it may be

corrected by reducing the distance between the

journal and the gear, or by installing a new thrust

Figure 9-1. Removing Cam Gear with Puller (Typical)

plate to replace the one which has been worn

too thin. If both the thrust plate and the thrust

3. Remove the screws holding the camshaft thrust

surfaces of the gear and journal are worn, it will

plate to the front of the cylinder block, which

be necessary to machine a small amount from

makes it possible to pull the camshaft forward

the shoulder against which the rear face of the

out of the bearings.

gear hub seats.

4. Unless engine is lying on its side, tappets must

be removed or lifted before camshaft can be

Remove enough so that a .005" to .009" feeler

pulled.

gauge may be fitted between the front of the

5. Remove tappet chamber cover.

journal and the rear of the thrust plate when the

6. Tappets can then be lifted out and lined up in

gear is assembled (Figure 9-2). If a condition of

sequence, for installation in the same location

insufficient end play is found, use one or two thin

unless inspection shows that they require

shims between the shoulder and the gear.

replacement. Refer to TOPIC 4. VALVES

INTAKE AND EXHAUST.

7. Before pulling the camshaft completely, check

the clearance of the bearing journals in the

bushing (or block in some models). To do this

use strips of feeler stock .25" wide with edges

dressed with a stone to eliminate any burrs or

feathered edges.

8. If clearance is equal to or greater than the wear

limits specified in TOPIC 1.

FITS AND

TOLERANCES, check the diameter of the

camshaft-journals to determine the next step.

Excess wear at these positions require

replacement of the shaft.

Figure 9-2. Checking Camshaft Thrust Clearance

R-104-1

3-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |