|

|||

|

|

|||

|

Page Title:

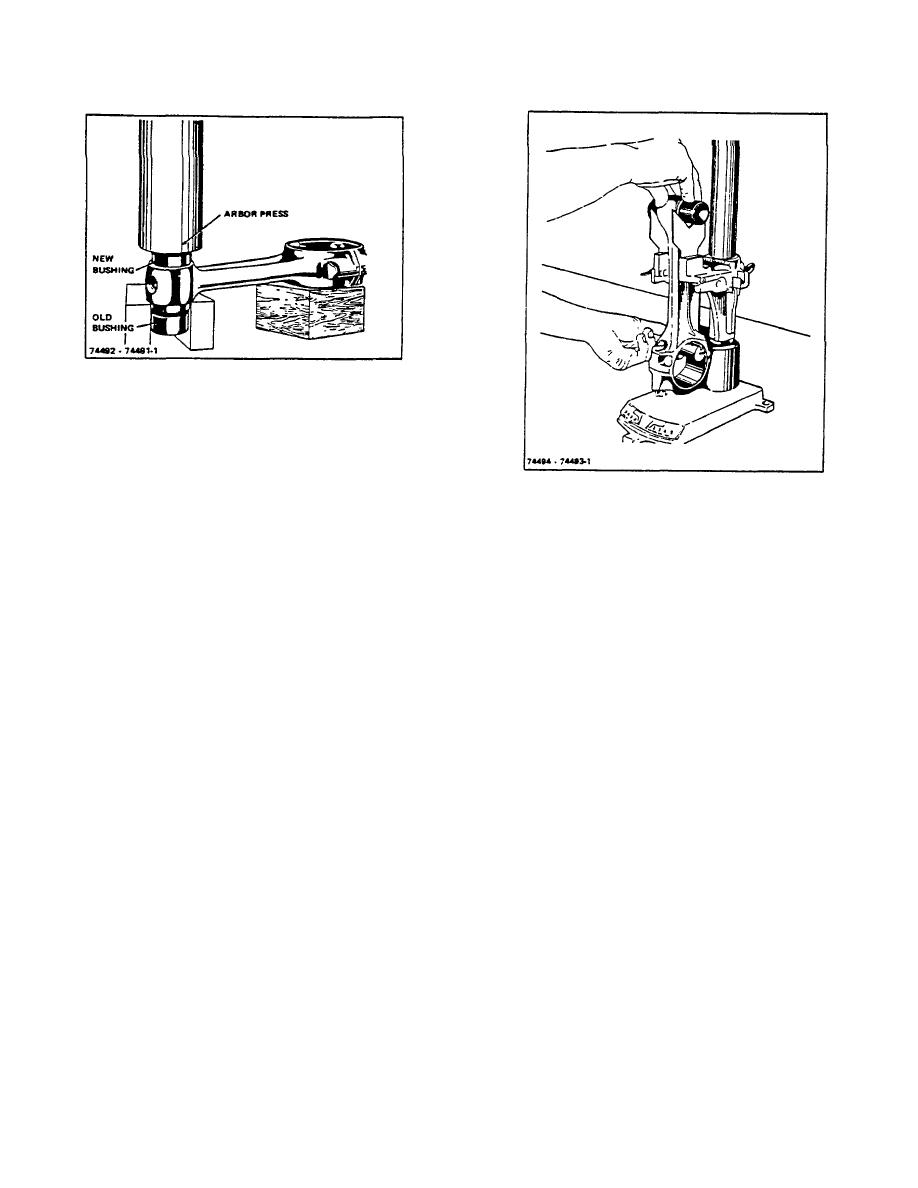

Figure 8-7. Pressing in Piston Pin Bushing |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Figure 8-7. Pressing in Piston Pin Bushing

Inspect connecting rod bearing shells for scoring,

discard bearing shells if any of these conditions are

apparent. Back of bearing shells should be inspected for

bright spots and discarded if any are found, as this

Figure 8-8. Checking Connecting Rod for Twist and

condition indicates they have been moving in their

Alignment

supports.

very easily, and can be tapped through the connecting

Inspect bearing shells for wear.

Specified inside

rod and into place without distorting the piston.

diameter of bearing shells when installed with bearing

cap retaining bolts tightened to specified torque is

For each piston, first install one of the piston pin retainer

2.1870" to 2.1865". This provides a running clearance of

rings, next heat the piston, and then Insert the piston pin

.0006" to .0022", new bearing shells must be installed

and install the other retainer ring.

when this clearance exceeds .0032". Refer to TOPIC 6,

paragraph D.

BEARING INSPECTION AND

Pistons are cam and taper ground, and this must be

INSTALLATION.

and measure the connecting rod

taken into consideration when checking alignment of the

bearings for wear and clearance with the crankshaft in a

assembly, since the diameter in line with the piston pin

similar manner If crankshaft is worn or damaged and

would be less at the top of the skirt than at the bottom.

must be reground, bearing shells of .002", .010", .020"

and .040" undersize, are available.

NOTE

Ring lands at top of piston are

G. PISTON AND ROD ALIGNMENT

smaller than skirt; therefore, check

alignment of rod along full length of

The piston pin hole in the connecting rod must be

skirt only.

parallel to, and in plane with, the large bore in the

bearing end of the connecting rod.

Regardless of the preliminary check made on the

connecting rod, the completed piston and rod assembly

Alignment may be checked on a fixture with the Piston

(Figure 8-9) must be rechecked and there must not be

pin assembled in the rod before assembling the piston

more than .002" twist or out of squareness checked over

(Figure 8-8). The connecting rod may be found twisted

a spread of approximately 4 inches. The connecting rod

or bent out of alignment due to wear on the rod bushings

can be bent or twisted with a bending bar to meet this

or bearings. In this case, the rod may be carefully

specification.

straightened with a bending bar.

The snap rings must be assembled in the grooves,

Assemble the pistons on the connecting rod by first

making sure they are fully seated in place.

heating them in some form of oven or in hot water to a

minimum temperature of 160F. When heated, the

piston pin enters the piston.

R-104-1

3-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |