|

|||

|

|

|||

|

Page Title:

PISTON AND PISTON RING INSPECTION |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Fitting a piston pin is a precision job. Oversize pins of

When the correct fit is obtained, the feeler may be

.005" and .010" are available, if desired. The specified

withdrawn with a pull of 5-10 pounds on the scale, with

pin clearance in the piston bosses will permit a "hand

the feeler inserted between the piston and the cylinder,

push" at ordinary room temperatures.

midway between the piston pin bosses where the

diameter of the piston is the greatest. Check the fit of

E. PISTON AND PISTON RING INSPECTION

the piston when it is approximately 2" down in the

As gummy deposits are not always easily removed with

cylinder bore in an inverted position.

fuel from piston walls and ring grooves, these parts may

be cleaned with a solvent and then blown off with dry

Piston skirt diameter of a new piston is 3.4120" to

compressed air. After cleaning, piston skirt, piston rings,

3.4170", measured at right angles to the piston pin.

and ring grooves should be thoroughly inspected.

New piston rings must always be used with new pistons.

If engine has been in service for some time, even though

CAUTION

same pistons are used again, it is advisable to use new

Do not use solvents containing

rings when the engine is re-assembled.

chemicals injurious to aluminum

alloy.

F. CONNECTING ROD INSPECTION

Piston skirt should be carefully inspected for score

marks or other indications of improper piston clearance.

Wash connecting rod assembly in clean solvent.

Any scored pistons should be replaced. Inspect inside

Measure outside diameter of piston pin to determine

of piston for cracks, any of which make it unfit for further

wear. Specified diameter of a new piston pin is .8591" to

use. Make certain that drilled holes in piston walls are

.8593". Check the bushing in the upper end of the

open and clean.

connecting rod for wear. Specified Inside diameter of

connecting rod bushing is .8595" to .8597". These

Check piston for wear by inserting it into cylinder bore

dimensions of pin and bushing provide a clearance of

and measuring clearance between piston and cylinder

.0002" to .0006". If clearance is close to or beyond this

wall. The cylinder walls and pistons must be perfectly

limit, replace connecting rod bushing.

clean and dry when fitting pistons in the cylinder bores.

Pistons should be fitted with the block and piston at

If bushing is worn, and the original pistons are to be

used with a service set of rings, an oversize piston pin

room temperature (68 - 70F).

may be obtained in .003" or .005" oversize.

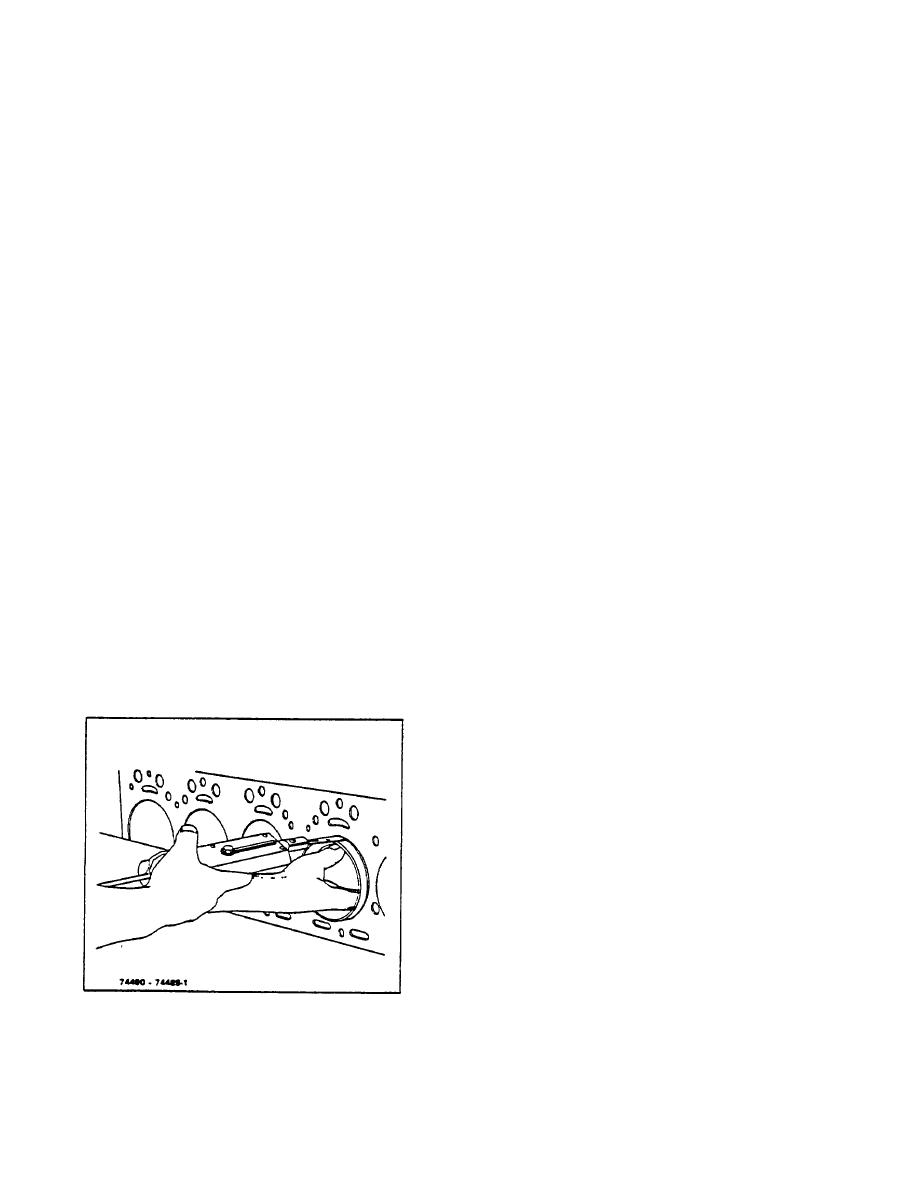

Check the piston fit in the bore using a half-inch wide

The piston pin hole in the piston and the bushing in the

strip of feeler stock, .003" thick, attached to a small scale

connecting rod may be honed to increase their diameter,

of approximately 15 lbs. capacity (Figure 8-6).

and to obtain the desired fit as shown in TOPIC 1. FITS

AND TOLERANCES.

NOTE

While the chart specifies a light push

fit of the pin in the piston, there is a

definite clearance of the piston pin in

the connecting rod.

Replace the bushing in the connecting rod if new pistons

and sleeves are used. Using an arbor press (Figure 8-7)

press out the old bushing and press in the new one after

which the bushing must be honed to obtain the correct fit

of the pin in the bushing as shown in TOPIC 1. FITS

AND TOLERANCES.

If there is an excess of stock in the piston pin bushing, it

may be reamed first, then honed. In any event, the final

operation should be done with a hone to obtain the

Figure 8-6. Checking Piston Fit in Bore

desired fit with better than 75% bearing area on the pin.

R-104-1

3-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |