|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

3-30. HYDRAULIC LIFT SYSTEM MAINTENANCE (cont)

d. Rotation Cylinder Assembly (cont).

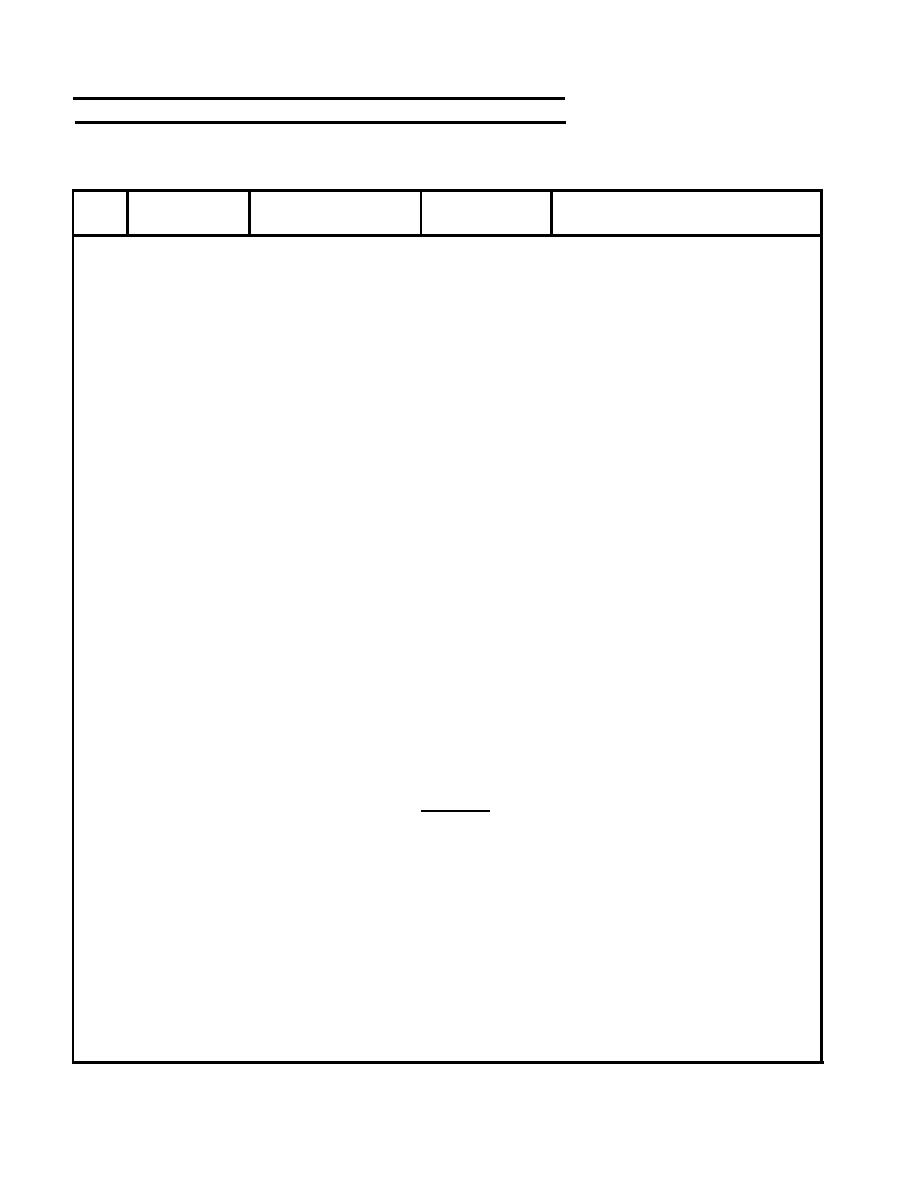

ITEM

REMARKS

ACTION

LOCATION

STEP

INSPECTION/REPAIR (cont)

Replace if deeply grooved, scored or nicked,

Inspect

Cylinder (27)

9

or damaged. Remove nicks or scratches

inside cylinder with medium grit emery

cloth polishing with a rotary motion

Replace if damaged, worn, cracked, or

Inspect

Bushing (26 and 29)

10

split

Replace if damaged, cracked, split, grooved

Inspect

All other parts

11

or scored

REASSEMBLY

Use 1-5/8 inches diameter sleeve; install

Install

a. Bushing (29)

12

Cylinder (27)

until centered

b. Two retaining rings (28) Install

Use 1-5/8 inches diameter sleeve; install

Install

a. Bushing (26)

Rod (24)

13

until centered

b. Two retaining rings (25) Install

Install

Seal lip towards cylinder

a. Seal (22)

14

Gland (23)

Lip towards rod

Install

b. Wiper (21)

Install

Curved side towards O-ring (19)

c. Back-up ring (20)

Install

d. O-ring (19)

e. Plug (18)

Install

Install

Piston (16)

a. O-ring (15)

15

Install

On O-ring (15)

b. Sealing ring (14)

Install

c. Wear ring (13)

CAUTION

Use care when performing following step not to damage parts.

Use clean hydraulic oil (refer to current

Lubricate and

a. Gland assembly (17)

16

Rod (24)

lubrication order)

slide on rod

Small diameter recess towards rod (24)

Slide on rod

b. Piston assembly (12)

Install

Tighten to 90-100 pounds foot torque

c. Washer (11) and cap

screw (10)

Use clean hydraulic oil (refer to current

Lubricate

d. Sealing ring (14)

lubrication order)

3-236

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |