|

|||

|

|

|||

|

Page Title:

ALTERNATOR REPAIR (cont) |

|

||

| ||||||||||

|

|

TM 10-3930-638-24&P

3-12. ALTERNATOR REPAIR (cont)

REMARKS

ACTION

ITEM

LOCATION-

STEP

TESTING (cont)

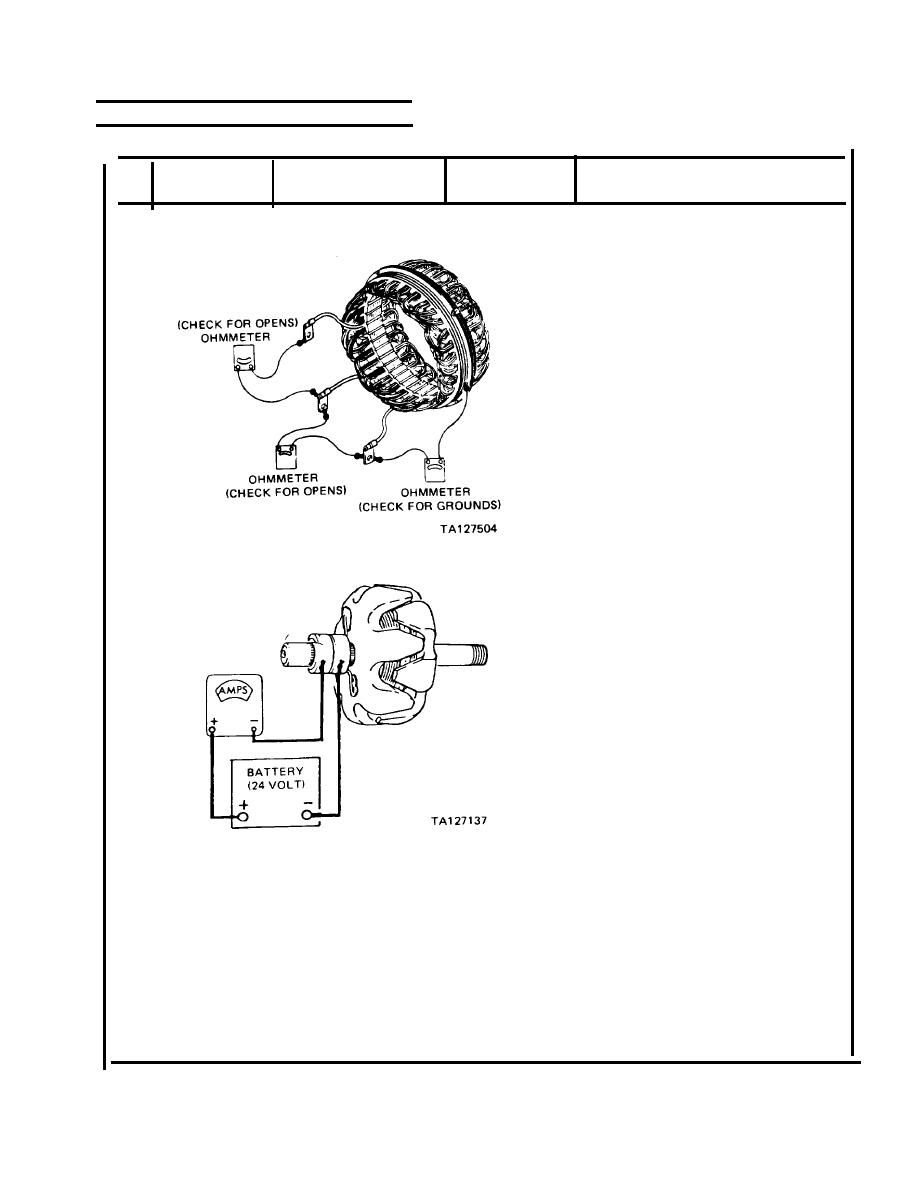

Use an ohmmeter to check. Connect test

Test

Stator (4)

14

prods as shown. If meter reading is

low when connected to any stator

lead and frame, the windings are

grounded. If the meter reading is high

when connected between each pair

of stator leads, the windings are open.

If stator winding is grounded or open

or if evidence of short is observed, re-

place stator

Use 110 volt test lamp. Connect test lamp

Test

Rotor (23)

15

from rotor slip ring to rotor shaft. If lamp

lights, the field windings are grounded.

Connect test lamp leads to each rotor slip

ring. If lamp fails to light, field windings

are open. Connect ammeter and battery

to rotor as shown. If ammeter indicates

more than 4.0 to 4.5 amperes, rotor field

windings are shorted. If field windings are

grounded, open or have shorted, replace

rotor

REASSEMBLY

Install

a. Grease slinger

Drive end

16

washer (30)

frame (1)

Use camshaft gear remover tool

Back up

b. Inside of bearing

area on end

frame (1)

Press on closed end of bearing until flush

Install

c. Ball bearing (29)

with end frame housing

Use valve guide installer tool until retainer

install

d. Ball bearing re-

seats against bearing (29)

tainer plate (28)

Until retainer (28) is securely mounted

Install and

e. Three screws (27)

tighten

3-99

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |