|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

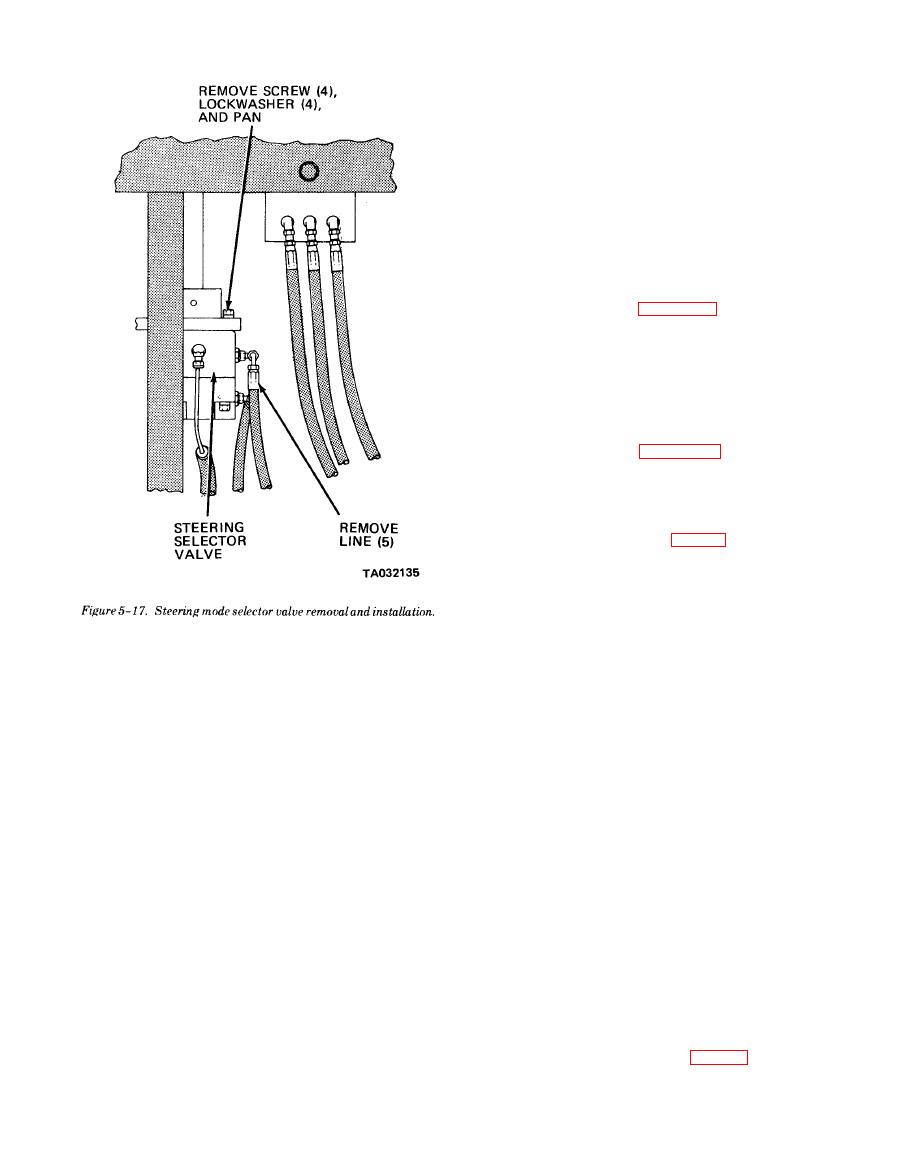

TM 10-3930-634-34

gripping with a downward pressure and turning coun-

terclockwise.

(2) Use a suitable puller and remove the steering

wheel (TM 10-3930-634-12).

(3) Use a suitable puller and remove the steering

pitman arm from the steering gear lever shaft.

(4) Tag and disconnect hydraulic lines as neces-

sary. Place dust caps over openings to prevent foreign

matter from entering the hydraulic system.

(5) Remove column from upper support bracket.

(6) Remove mounting flange bolts and remove

gear from chassis.

ble the steering gear assembly.

d. Cleaning and Inspection.

(1) Clean all parts thoroughly, using solvent

P-D-680, or equal.

(2) Inspect the components for wear, burrs, scored

areas and other damage.

(3) Replace all defective parts.

the steering gear assembly.

f. Installation. Install the steering gear assembly in

the reverse order of removal.

g. Thrust Bearing Adjustment Procedure.

(1) Remove capacrews (36, fig. 5-19) holding up-

per cover (38) and remove cover and jacket tube assem-

bly (8).

(2) Reassemble screws in actuator housing (50),

using 3/8-inch thick spacers under the head of the

screws. This is to hold the actuator (46) and cam as-

sembly (70) in the gear when making the adjustment.

(3) Straighten prong of lockwasher (41). Remove

ahead driving conditions, the centering springs in the

nut (40), tongued washer (42), upper thrust washer

actuator assist in giving the system road feel. The feel

(43) and bearing (44).

and steering effort created by the springs is constant

(4) Insure that the threads of the nut and cam

for any steering condition and is tailored to suit the

shaft are free of interference by running the nut onto

vehicle application by changing the spring load to give

the cam shaft by using only the fingers to turn the nut.

the degree of steering effort desired.

If the nut cannot be tightened in this manner, use of a

(4) Whenever the operator's efforts at the steering

thread file or other means will be necessary to correct

wheel overcome the centering effect of the springs, the

this fault until the nut goes on freely.

valve spool is moved axially, restricting one of the re-

(5) Reassemble thrust washers, bearings, tongued

turn passages to the outlet port. This causes an imme-

washers (with internal lug), pronged washer (with 13

diate increase in pressure at one of the cylinder ports

external prongs), and nut.

and in one end of the cylinder. At the same time, the

(6) Tighten nut to 10 lb-ft torque then back off

other return passage is enlarged, allowing the oil from

nut 10-20 degrees which can be done by moving the

the discharging end of the cylinder free passage to the

nut approximately the width of one and one-half lugs.

outlet port and return to the reservoir. The immediate

Bend the lug, nearest alinement, with a notch in the

effect is increased pressure in one end of the cylinder

nut into a notch root on the nut.

to actuate the piston which applies hydraulic power di-

(7) Reassemble upper cover and jacket tube as-

rectly to the steering gear pitman arm or linkage part

sembly and attaching parts.

to which the cylinder is attached. Full pressure is ob-

tained with a spool travel of about sixty-five one-thou-

5-20. Rear Power Steering Valve

sandths of an inch. The slightest movement results in

a pressure differential.

a. Removal. Tag and disconnect the hydraulic hoses

b. Removal.

from the rear power steering valve (fig. 5-20). Meas-

(1) Remove the cover from the steering wheel by

ure and record the length of the valve link before re-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |