|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-34

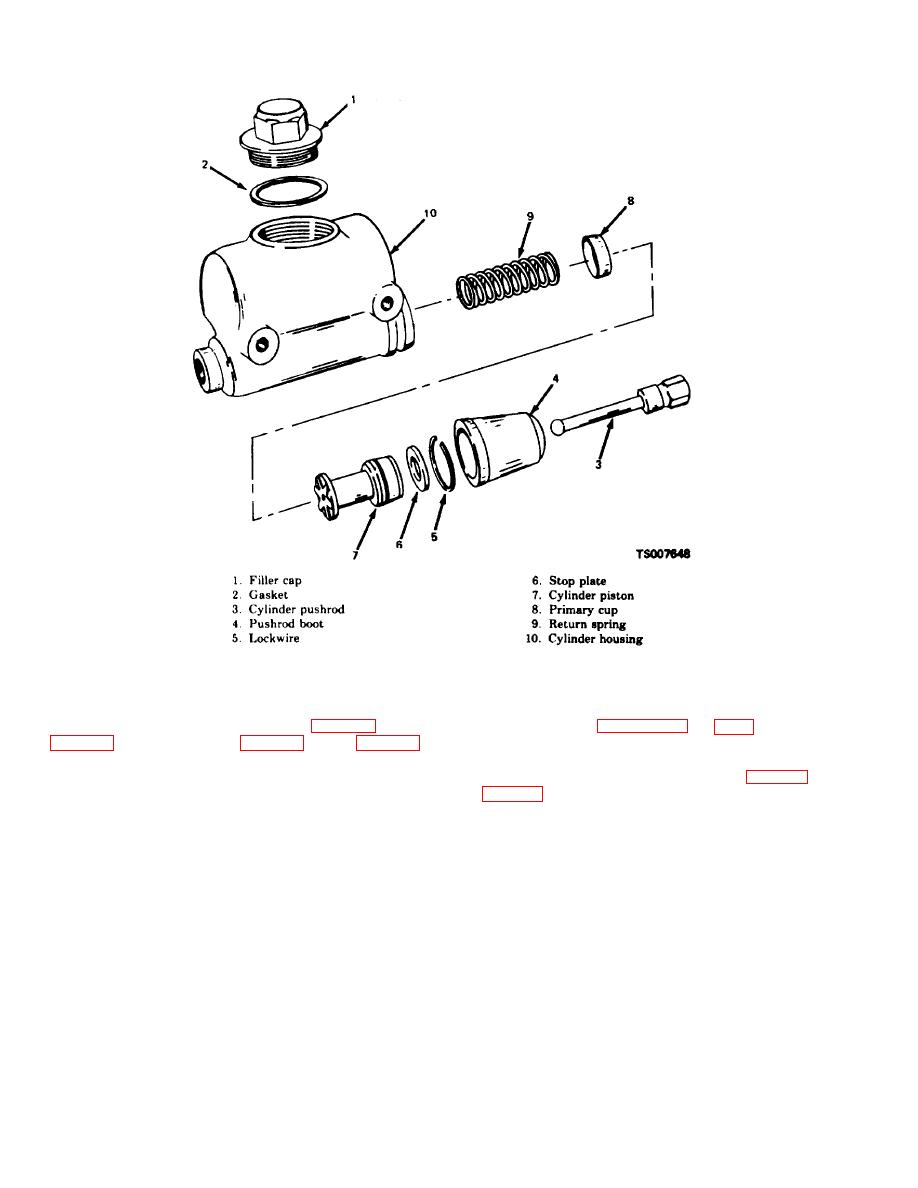

Figure 11-3. Inching Brake Master Cylinder, Exploded View.

11-9.

Cleaning and Inspection

11-10.

Reassembly

a. Discard the primary cups (10, fig. 11-2, and 8,

a. Refer to figures 11-2 and 11-3 and reassemble

the service and inching brake master cylinders.

b. Clean all other metal parts of the brake master

Note the following:

b. After installing the spring (11, fig. 11-2, and 9,

cylinder in denatured alcohol; dry thoroughly with

compressed air.

c. Inspect the tank for cracks, distortion, and

tank, lock them in place with the stop plate and lockwire

retainer.

damaged threads. Check the bore of the tank for pitting

or scoring. Replace if damaged.

d. Inspect all other parts for cracks, damaged

11-11.

Installation

threads, distortion, and other damage; replace damaged

Install the brake master cylinders, bleed the brake

parts.

system and adjust the brake linkage (TM 10-3930-632-

12).

Section IV. WHEEL CYLINDERS

When brake fluid under pressure is applied to the wheel

11-12.

General

cylinder, both pistons are pushed outward in the cylinder,

The wheel cylinders are mounted on the brake

forcing the brake shoes apart. This

backing plate, positioned between the brake shoes.

11-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |