|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-34

broken teeth on the ring gear, distortion, worn or out-of-

one revolution. If the flywheel is eccentric more than

round bolt holes, and other damage. If the ring gear is

0.008 inch, loosen and TM 10-3930432-34 retighten the

damaged, replace as follows:

flywheel mounting bolts and recheck eccentricity. If

(1) Cut the ring gear with a torch or hack saw

eccentricity still exceeds 0.008 inch, replace the flywheel.

and remove the ring gear from the flywheel 127).

CAUTION

When cutting the ring gear, be extremely careful

not to damage the flywheel.

(2) Heat the replacement ring gear in an oven

and cool the flywheel in water or in a refrigerator.

(3) Position the replacement ring gear on the

flywheel. As the ring gear and flywheel approach the

same temperature, the ring gear will contact to a tight fit

on the flywheel.

9-25.

Installation

a.

Position the flywheel housing (35) on the

engine block. Secure with screws (29 and 32, fig. 9-26)

and washers (30 and 33).

b.

Position the flywheel (27, fig. 9-20) on the

crankshaft (26); secure with six bolts (23), lockwashers

(25), and nuts (24). Tighten the nuts to 35 to 40 ft/lbs

c.

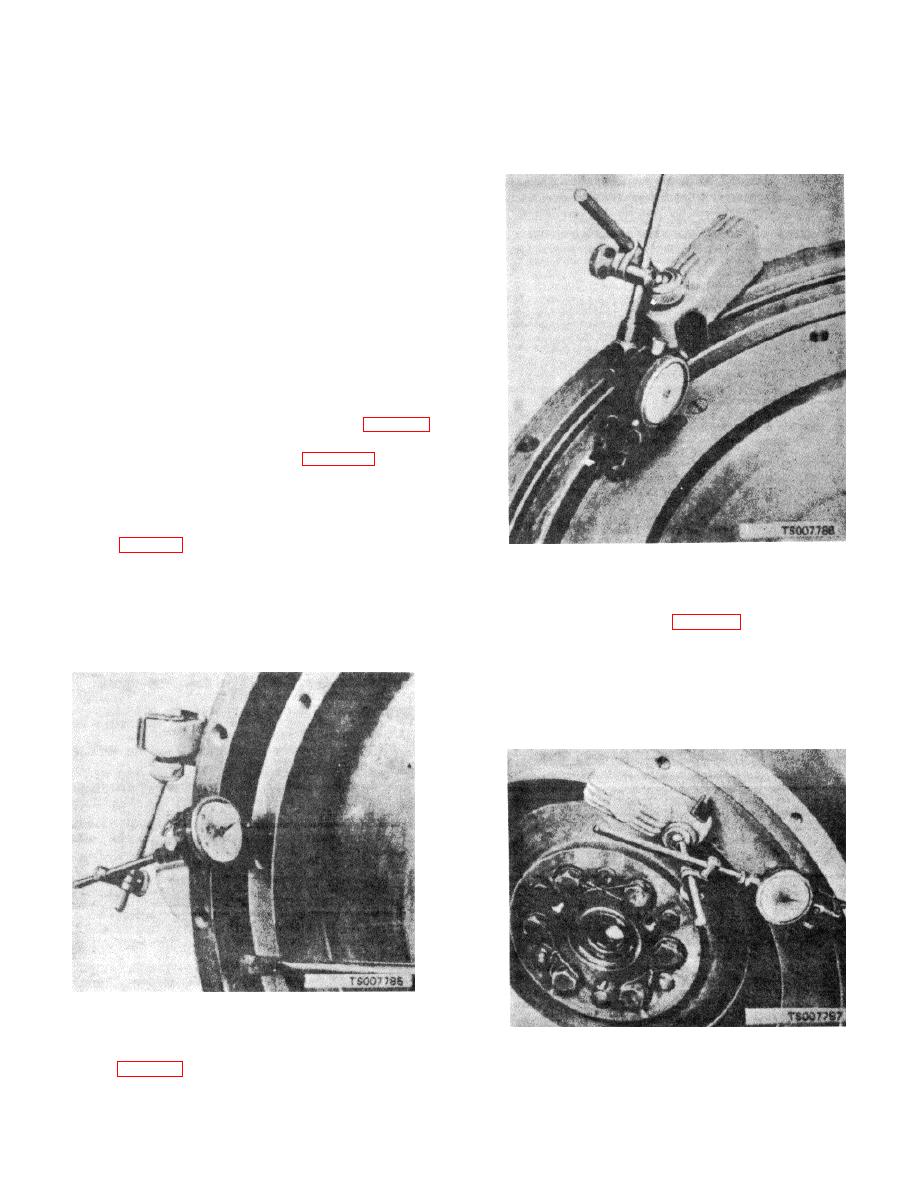

Check flywheel runout by mounting a dial

indicator (fig. 9-21) and rotating the crankshaft through

one full revolution. Hold pressure against the flywheel to

Figure 9-22. Checking Flywheel Eccentricity.

eliminate crankshaft end play. If flywheel runout exceeds

0.008 inch, remove the flywheel and clean the crankshaft

e.

Check runout of the flywheel housing face by

flange and flywheel seat. Install the flywheel and

mounting a dial indicator (fig. 9-23) and rotating the

recheck runout. If runout still exceeds 0.008 inch,

crankshaft through one revolution.

Hold pressure

replace the flywheel.

against the flywheel to eliminate end play. If runout

exceeds 0.008 inch, clean the mounting surfaces of the

flywheel housing and the block. Recheck flywheel

housing runout. If the runout is still not within limits,

replace the flywheel housing.

Figure 9-21. Checking Flywheel Runout.

d.

Check flywheel eccentricity by mounting a dial

Figure 9-23. Checking Flywheel Housing Runout.

indicator (fig. 9-22) and rotating the crankshaft through

9-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |