|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-12

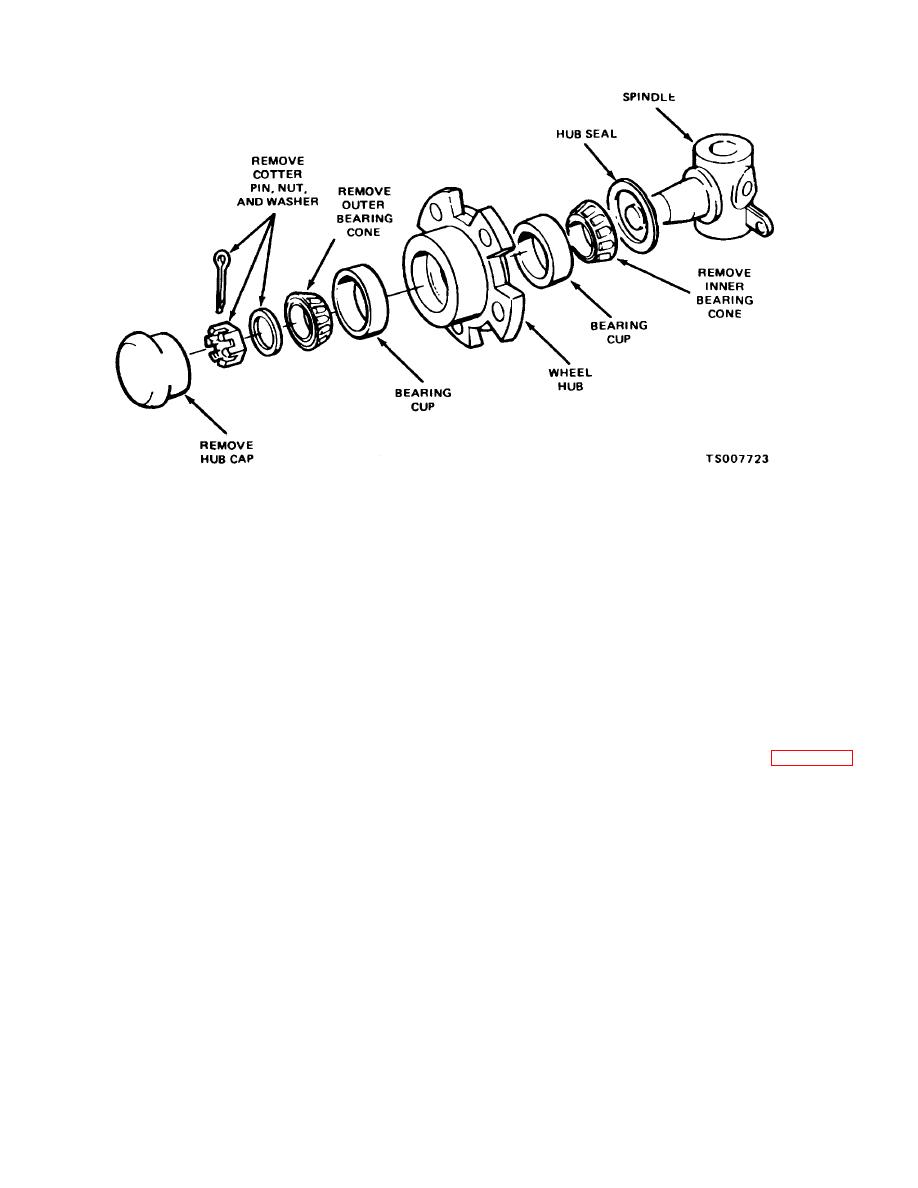

Figure 4-50. Wheel Bearings and Hub, Disassembly and Reassembly

WARNING

(5) Inspect the bearing cups for scoring,

scratches, nicks, and other damage. If damaged, drive

Dry cleaning solvent, P-D-680, used to

the cups from the wheel hub using a soft drift. Press in

clean parts is potentially dangerous to

new bearing cups, taking care not to damage the cups

personnel and property. Avoid repeated

or hub.

and prolonged skin contact. Do not use

c. Packing Bearings. Pack the bearing cones

near open flame or excessive heat. Flash

and the interior of the hub with the lubricant

point of solvent is 100F. -138F. (38C.

recommended by the lubrication order. Take care to

-60C.).

b. Cleaning and Inspection.

prevent dirt or grit from contaminating the grease.

During reassembly, pack the ring gear of the drive

(1) Clean the bearing cones by flushing up

wheels with grease as directed in paragraph 4-79c.

and down in dry cleaning solvent P-D-680. If necessary,

d. Reassembly.

tap the large side of the bearing against a soft wooden

(1) Reassemble the bearings and hub on

block to dislodge solidified grease. Dry bearings with

the spindle or steering knuckle as shown in figure 4-50.

clean, dry compressed air. Direct the stream of air at

(2) When installing the slotted nut, tighten

the bearing so that the rollers and cage will not spin.

the nut while rotating the wheel in both directions until

Dip bearings in light oil immediately after cleaning.

the bearings bind slightly during rotation. Back off the

(2) Clean the hub the spindle with a cloth

nut by 1/6 to 1/4 turn and lock the position of the nut

dampened with dry cleaning solvent P-D-680.

with a cotter pin.

(3) For the drive wheels, clean the ring

(3) Remove the blocking and lower the

gear and pinion as directed in paragraph 4-79.

truck to the ground.

(4) Inspect the bearing cones for pitting,

scoring, wear, and cracked cages, and for rough or

binding operation. Replace damaged bearings.

Section XX. BRAKES

4-72. General

drum assemblies are secured to the spindle supports.

The brakes are hydraulically operated by the brake

The service brakes are mounted on the front axle ends.

master cylinder, which is

The brake drum rotates with the wheels and the brake

4-65

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |