|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-12

c. Installation.

(2) Disconnect the exhaust connector from

the manifold (fig. 4-41).

(1) Install the oil filter and related parts as

(3)

Disconnect the positive crankcase

shown in figure 4-47. Use a new filter element during

ventilation piping from the intake and exhaust manifold

reassembly.

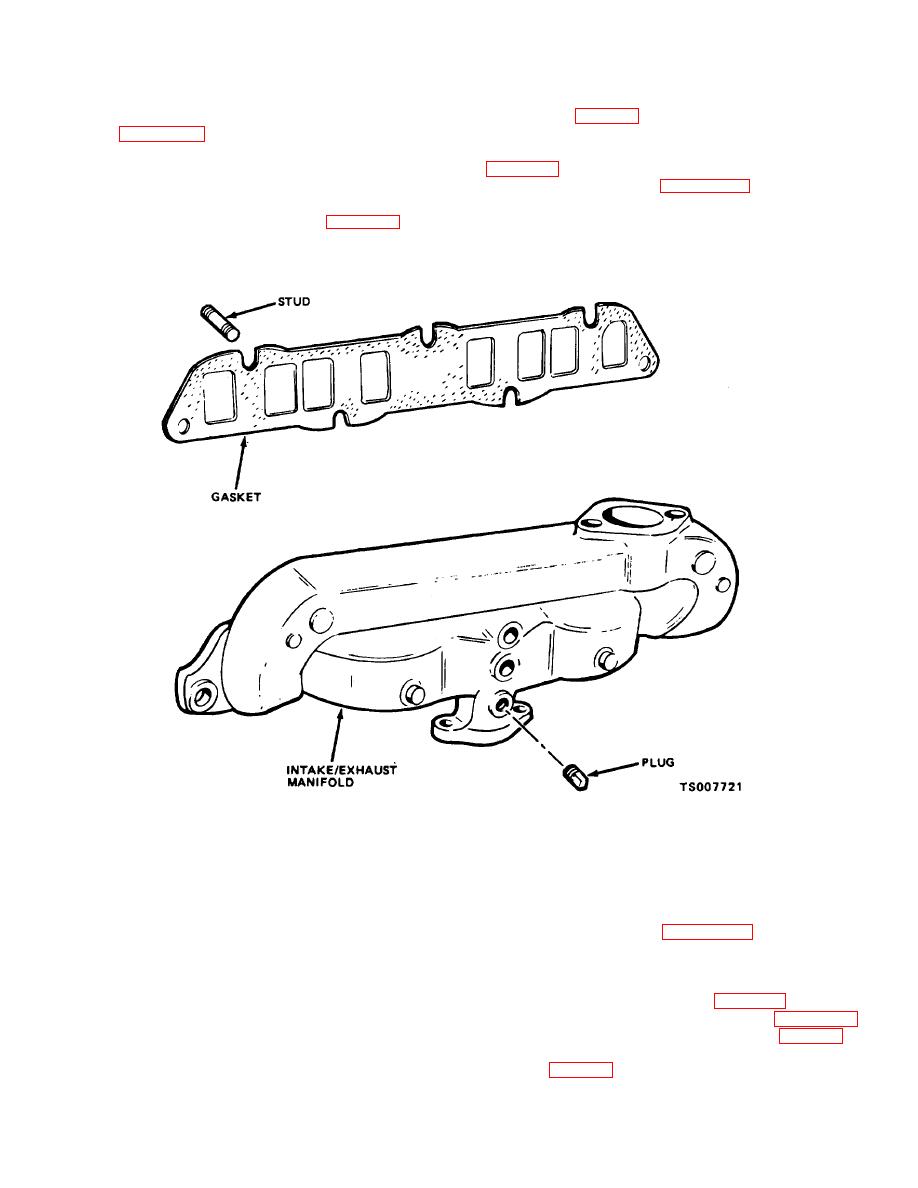

4-68. Intake and Exhaust Manifold

(4) Refer to figure 4-48 and remove the

a. Removal.

intake and exhaust manifold from the engine.

(1) Remove the carburetor (para 4-42) and

disconnect the air inlet hose from the air cleaner (fig. 4-

32).

Figure 4-48. Intake and Exhaust Manifold, Removal and Installation

WARNING

(3) Inspect for loose or damaged studs.

(4) Replace the gasket; replace other parts

Dry cleaning solvent, P-D-680, used to

if defective.

clean parts is potentially dangerous to

c. Installation.

personnel and property. Avoid repeated

(1) Refer to figure 4-48 and install the

and prolonged skin contact. Do not use

intake manifold, using a new gasket. Tighten the stud

near open flame of excessive heat. Flash

nuts to 25 to 30 foot-pounds.

point of solvent is 100F.-138F. (38C.-

(2)

Install the positive crankcase

60C.).

b. Cleaning and Inspection.

ventilation piping on the manifold (para 4-47).

(3)

Install the carburetor (para 4-42).

(1) Clean dirt from the manifold with a wire

Connect the air inlet hose to the air cleaner (fig. 4-32).

brush; then clean with a cloth dampened in dry cleaning

(4) Connect the exhaust connector to the

solvent P-D-680.

manifold (fig. 4-41).

(2)

Inspect the manifold for cracks,

warping, damaged sealing surfaces, corroded areas,

damaged threads, or other defects.

4-63

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |