|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-12

armature shaft for free rotation. Replace if damaged.

c. Testing.

(1) Use a battery known to be in good

condition and an accurate voltmeter. Connect the

positive lead of the voltmeter to the positive terminal of

the battery, and the negative lead to the negative

(grounded) terminal of the battery. Record the voltage

reading.

(2) Pull the high tension lead from the

ignition coil to prevent the engine from starting during

the starting motor test.

(3)

Connect the positive lead of the

voltmeter to ground and the negative lead of the

voltmeter to starter switch terminal. Turn and hold the

ignition switch to the START position and read the

voltmeter.

(4) Compare the voltmeter reading with

the previously recorded voltmeter reading.

If the

voltage drop is more than 4 volts, or if the second

reading is less than 8 volts, the starting motor is

probably faulty.

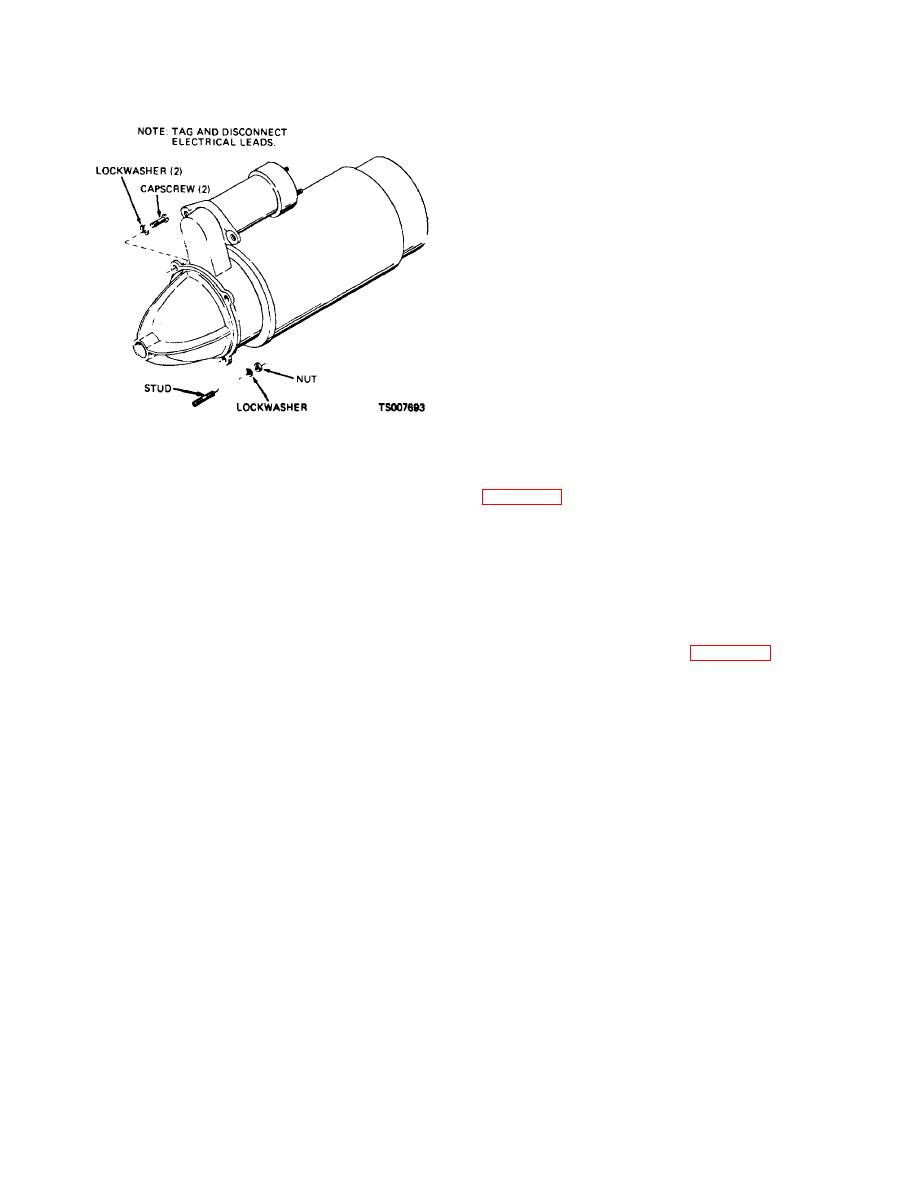

Figure 4-20. Starting Motor, Removal and Installation

d. Installation.

(1) Install the starting motor as shown in

WARNING

Dry cleaning solvent, P-D680, used to clean

(2)

Connect the battery cable to the

parts is potentially dangerous to personnel

battery and to the starting motor.

and property.

Avoid repeated and

(3) Check the operation of the starting

prolonged skin contact. Do not use near

motor. Make sure it cranks the engine as required.

open flame or excessive heat. Flash point

of solvent is 100F. -138F. (38C. -60C.).

4-34. Ignition Distributor

b. Cleaning and Inspection.

a. Distributor Point, Repair and Replacement.

(1) Clean the exterior of the starting motor

(1) To check the distributor points, remove

with a cloth dampened with dry cleaning solvent P.D-

the distributor cap as shown in figure 4-21. Lift the rotor

680; dry thoroughly. Take care to prevent solvent from

from the distributor shaft and remove the housing cover

entering the starting motor.

seal.

(2) Inspect the starting motor for cracks,

bent or damaged terminals, signs of overheating,

damaged pinion teeth, and other damage. Check the

4-35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |