|

|||

|

|

|||

|

Page Title:

Section II. HYDRAULIC PUMP MOTOR |

|

||

| ||||||||||

|

|

TM 10-3930-631-34

(4) If lamp lights, field winding is grounded.

(6) Secure bearing housing with screws (3).

Remove winding and check to locate short. If short

(7) Place motor housing in a vertical position.

cannot be located and repaired replace field windings.

Use a hoist and carefully lower armature assembly with

(5) Pack bearing (6) half full of grease (GA).

housing. Do not damage commutator, core or field

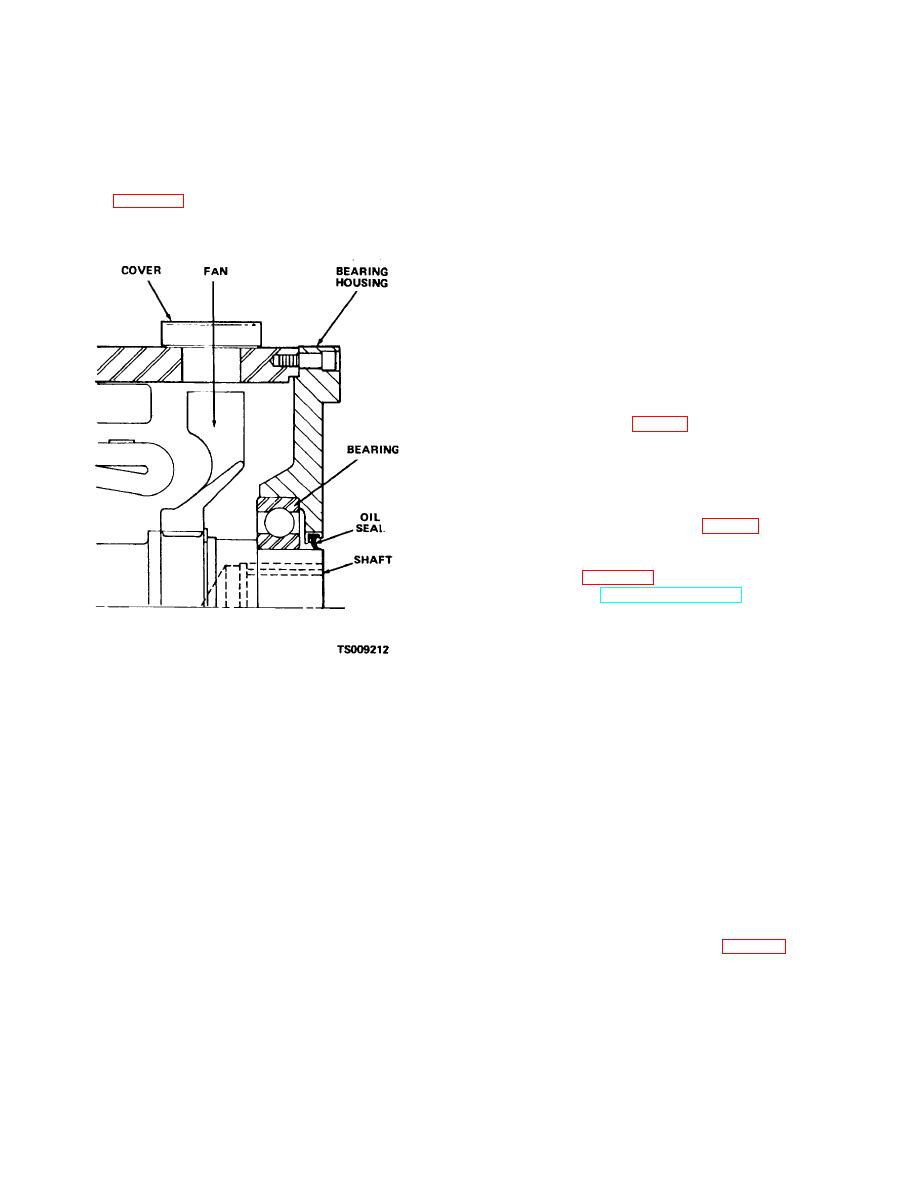

Install seal (5) and bearing (6) in bearing housing (4).

windings.

Install bearing housing on housing (33) with seal as

(8) Install brush holders (22) and springs (23)

shown in figure 8-9.

on rocker arm (26). Connect leads (13,14 and 15) to

windings and rocker arm.

(9) fill bearing (27) half full of grease (GAA) and

install bearing in housing (28). Install assembled rocker

arm in housing and secure with screws (24) and lock

washers (25).

(10)Install bearing housing over commutator and

secure with screws (12).

(11)Refer to paragraph a. above and install

brushes.

(12)Install covers (1) and (2) on drive motor.

f. Installation.

(1) Place drive motor in position under truck.

Install new gasket (9, fig. 3-8) on carrier. Use a suitable

jack and lift drive motor into position in line with

differential carrier. Guide motor shaft to engage splines

of pinion gear in carrier and aline motor mounting holes

with holes in differential carrier.

(2) Secure motor to carrier with screws (5) and

lock washers (6). Install disk (5, fig. 4-1) on motor shaft

and secure with nut.

(3) Install parking brake bracket and calipers on

drive motor (para 4-1) and connect parking brake

linkage. Refer to TM10-3930-631-12 and adjust parking

brake linkage.

(4) Connect electric cables to drive motor.

Connect leads to thermal relay on motor.

(5) Install drip pan and floor and toe pates. Fill

axle and differential with proper grade of oil (LO10-3930-

631-12).

Figure 8-9. Installing bearing housing.

Section II. HYDRAULIC PUMP MOTOR

closes micro-switches allowing the current to flow to the

8-3. Description

pump motor.

a. The hydraulic pump and motor are mounted

8-4. Repair of Hydraulic Pump Motor

horizontal to the frame to the rear of the drive motor. As

a. Brush Replacement.

the motor drives the pump, hydraulic oil is delivered

(1) Disconnect battery receptacle and discharge

under pressure to the control valve. From the control

capacitors.

valve the oil is sent to actuate lifting, tilting and shifting

(2) Raise front end of truck and securely block

cylinders.

b. The pump motor is a ventilated, sealed ball

truck. Remove drip pan to gain access to hydraulic

pump and motor.

bearing type motor. The motor is supported at each end

(3) Remove rear cover (13, fig. 8-10) to gain

on brackets attached to the truck frame. Current is

access to brushes.

supplied to the motor when the key switch is on and

either lift, tilt or side shift control valve levers are

actuated. Movement of the levers

8-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |