|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

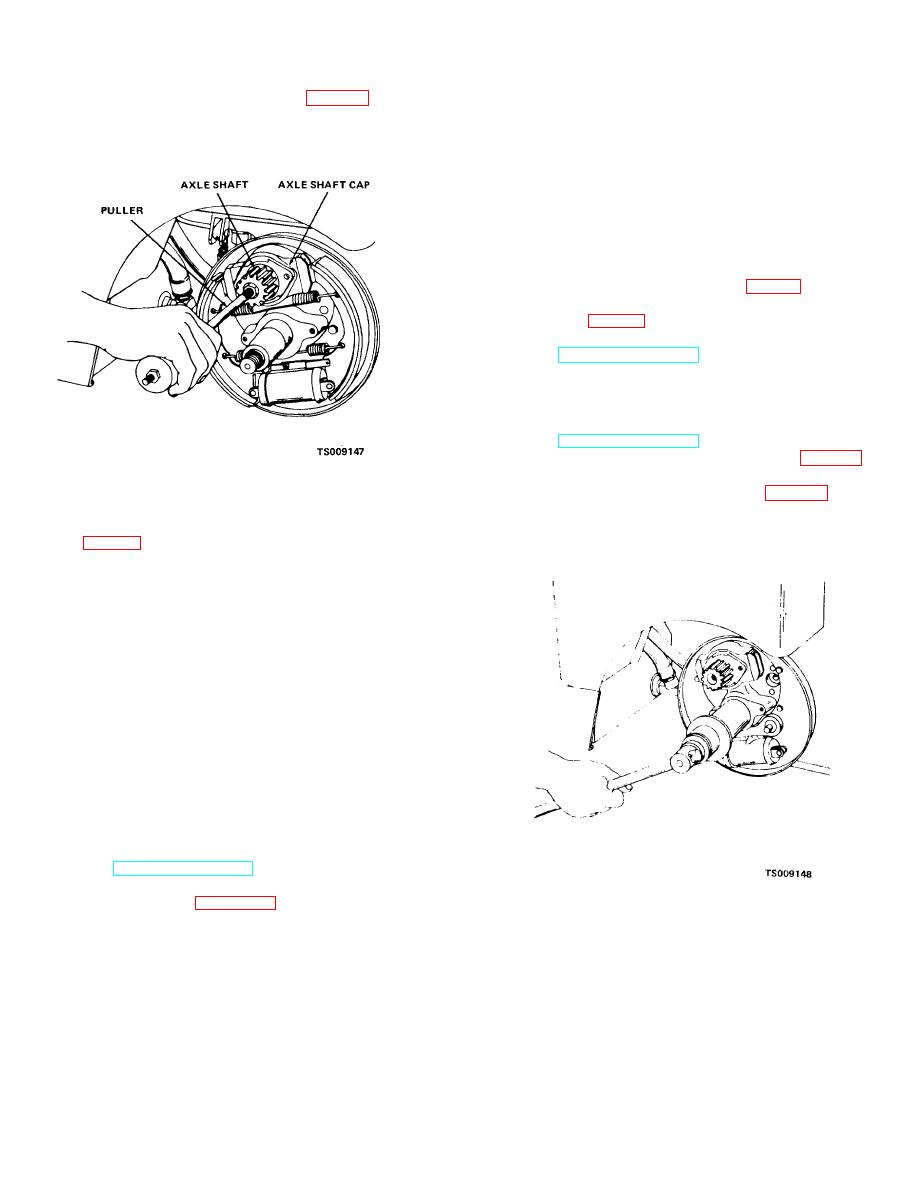

(3) Install threaded puller (fig. 3-6) into

(4) Install greased bearing assembly (22) on

threaded end of axle shaft and carefully remove

shaft. Aline keyed washers (20 and 21) with groove

shaft with axle cap and bearing attached.

in shaft and slide into position on shaft.

(5) Install nut (19) and tighten on shaft.

Tighten enough to produce a slight pre-load on the

bearings. Secure nut with tabs on washer (20).

(6) Position assembled axle shaft in

housing. Use care when installing axle shaft to

prevent damage to oil seal in housing. Aline splines

on shaft with splines in differential gears. Using a

soft mallet drive axle splines into differential.

(7) Aline holes in axle cap (fig. 3-6) with

holes in axle housing and secure cap to axle with

screws (16, fig. 3-5) and lock washers (17).

(8) Install dust shield, grease seal and drive

wheel (TM10-3930-631-12).

3-9. Spindle

a. Removal.

(1) Remove drive wheel, grease seal and

dust

shield (TM10-3930-631-12).

(2) Remove self-locking nut (13, fig. 3-5)

from spindle (14).

Figure 3-6. Removing axle shaft.

(3) Install suitable puller (fig. 3-7) and

remove spindle from housing. Use pipe spacer and

(4) Straighten locking prongs on tab washer

large washer over spindle. Tighten nut (13) against

(20, fig. 3-5) and remove nut (19) and washers (20

washer to free spindle from housing.

and 21) from shaft.

(5) Using a suitable press, press bearing

assembly (22) from shaft. Remove oil seal (23) and

axle cap (24) from shaft. Discard oil seal.

CAUTION

When removing bearing, exert pressure on

inner race of bearing and not on rollers. Use

care to prevent damage to axle cap.

(6) Remove oil seal (26) from axle housing.

Discard seal.

b. Cleaning, Inspection and Repair.

(1) Clean all parts in cleaning compound,

solvent (Fed. Spec. P-D-680).

(2) Inspect spindle and nut for wear and

damage.

(3) Replace oil seals. Replace worn or

damaged parts.

(4) Grease bearings and shaft pinion as

noted on LO 10-3930-631-12.

c. Assembly and Installation.

(1) Refer to figure 3-5 and assemble and

Figure 3-7. Removing spindle.

install axle shaft as follows:

(2) Use a seal driver and install new oil seal

b. Cleaning, Inspection and Repair.

(26) in axle housing.

(1) Clean all parts in cleaning compound,

(3) Install axle cap (24) and new oil seal

solvent (Fed. Spec. P-D-680).

(23) on axle shaft (25).

(2) Inspect spindle and nut for wear and

damage.

(3 )Replace worn or damaged parts.

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |