|

|||

|

|

|||

|

Page Title:

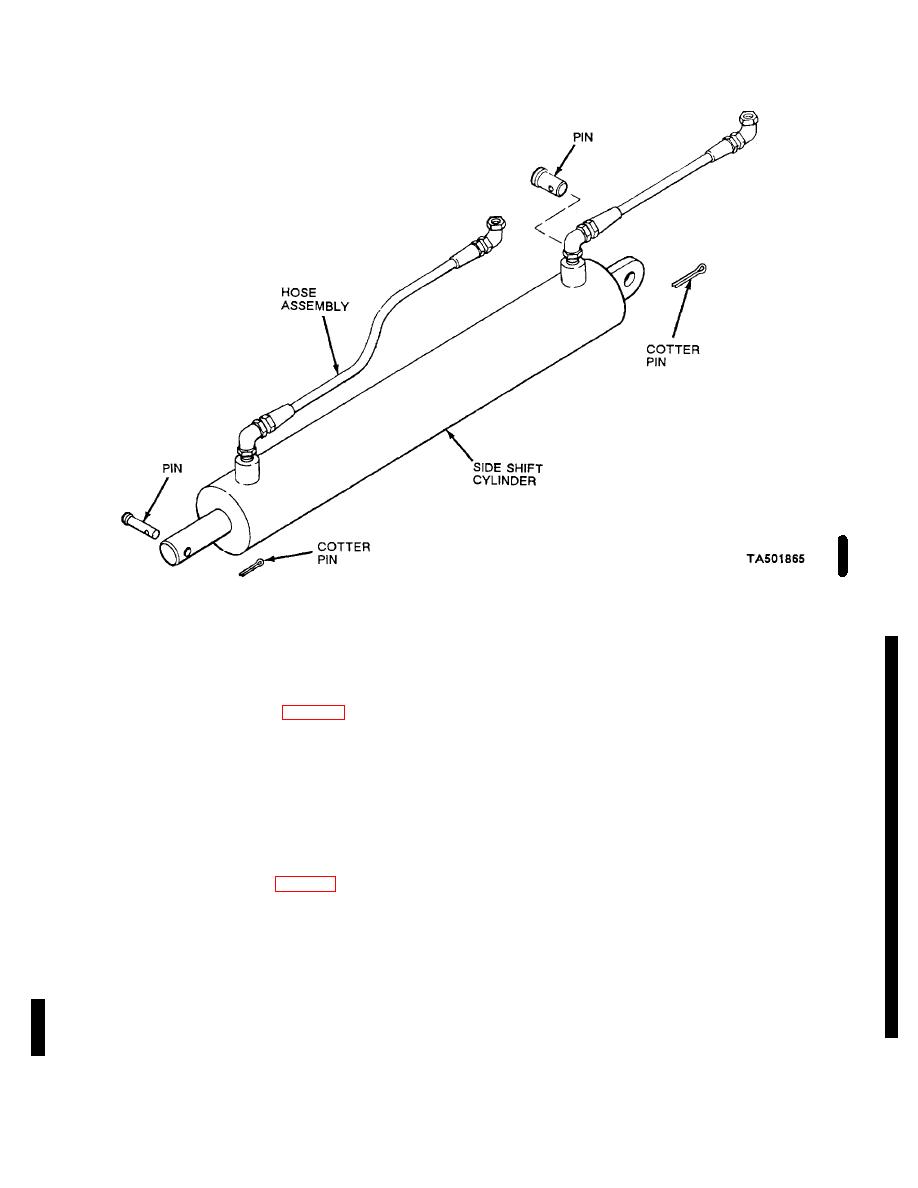

Figure 4-44. Side shift cylinder, exploded view. |

|

||

| ||||||||||

|

|

TM 10-3930-631-12

Figure 4-44. Side shift cylinder, exploded view.

(3) Remove cotter pins and cylinder pins

(2)

Work through cutout in drum and

from both ends of cylinder and remove cylinder from

remove setscrew (11) and pin (12) and disengage shaft

carriage.

from shaft extension. Remove retaining ring (13) and

b. Installation.

washer (14). Remove shaft from swivel.

(3) Remove pin (15) from shaft. Remove

(1) Install cylinder (fig. 4-44) on carriage

backup rings (16) and packings (17) from shaft (27).

with ends of cylinder in line with mounting brackets.

Discard backup rings and packing.

(2) Secure cylinder to carriage with cylinder

(4) Remove nuts (18) and separate swivel

pins and cotter pins.

(19) and drum (20). Remove cover (21) from spring and

(3) Remove plugs or caps from cylinder and

cup (26).

hoses and connect hoses to cylinder.

(5) Remove pin (22) and disengage shaft

(4)

Operate side shift mechanism and

extension (23) from hub (24). Remove hub and spring

check hoses and cylinder for leaks.

(25) from cup (26).

4-58. Side Shift Hose Reel

c. Cleaning, Inspection and Repair.

a. Removal.

WARNING

(1) Unreel hoses (1, fig. 4-45) from reel (2)

Cleaning compound, solvent (Fed.

Disconnect hoses from fittings at end of reel and from

Spec. P-D-680), used for cleaning, is

junction block (3) inside reel. Cap or plug hoses to

potentially dangerous to personnel and

prevent entrance of foreign matter.

property. Do not use near open flame.

(2) Remove two long screws (4) and lock

Flash point of solvent is 1000F to 1380F

washers (5) securing hose reel to mounting block (6) on

(380C to 590C).

inner mast.

b. Disassembly.

(1)

Clean all metal parts in cleaning

compound, solvent (Fed. Spec. P-D-680) and dry

(1)

Remove two screws (7) and lock

thoroughly.

washers (8) and remove swivel block (9) from reel.

Remove packings (10).

Change 2 4-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |