|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-12

c. Cleaning and Inspection.

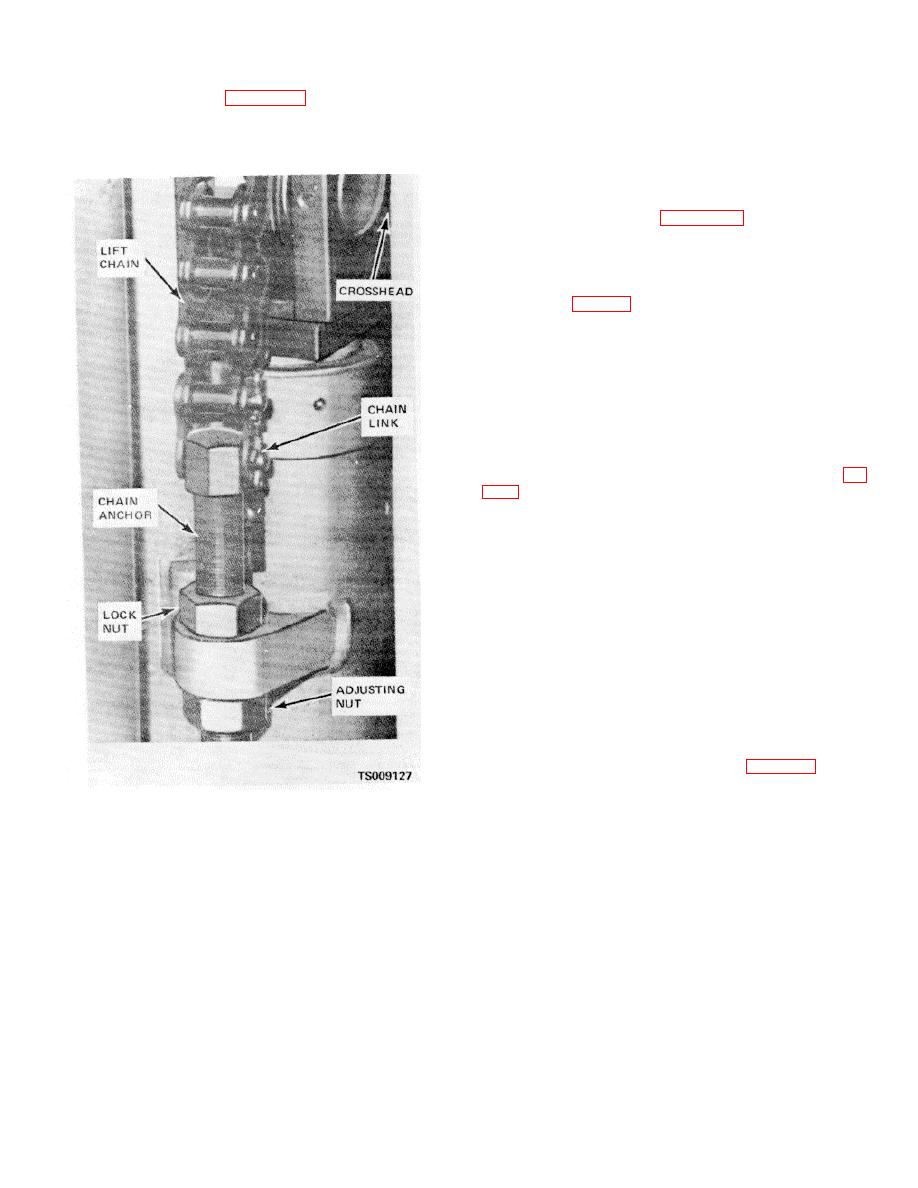

(4) Refer to figure 4-43 and remove cotter

pins and chain links from chain anchors attached to the

(1) Clean chains with cleaning compound,

cluster cylinder. Lift chains over chain bearings and off

solvent (Fed. Spec. P-D-680) and dry thoroughly.

of cross head and remove chains From mast.

(2) Inspect chains for bent, cracked, or

damaged links. Replace defective links.

(3) Lubricate chains with oil IOE).

d. Installation.

(1) Refer to figure 4-43 and place chains

through cross heads and around chain bearings.

(2) Connect chains to chain anchors with

chain links and cotter pins.

(3) Lower other ends of chains to anchors

on carriage (fig. 4-42) and attach chains to anchors with

chain links and cotter pins.

(4)

Operate lift mechanism and check

chains for bending or uneven operation. If cylinder

cluster is fully retracted, carriage should be level and

forks should not touch floor. Refer to e below to adjust

chains.

e. Chain Adjustment.

(1) Check to see that mast is in a vertical

position and that cylinder cluster is fully retracted.

(2) Loosen locknuts and adjusting nuts (fig.

(3) Turn the adjusting nuts to vary chain

length. Tighten or loosen the chains until the chains are

a snug fit and forks barely clear the floor.

(4) Tension must be equal on both chains

and carriage must be level.

(5) Tighten locknuts. Check adjustment to

see it has not been disturbed.

(6) Operate lift mechanism and check chain

operation.

(7) Lower carriage and fully retract cylinder

cluster. Check for carriage level and forks clearing floor.

4-57. Side Shift Cylinder

a. Removal.

(1) Lower carriage and forks to ground.

Shift carriage to center position. Shut off truck.

(2) Disconnect hoses (fig. 4-44) from

fittings in cylinder. Cap or plug hoses and fittings to

prevent entrance of foreign matter.

Figure 4-43. Lift chains and chain anchors,

installed view.

4-50

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |