|

|||

|

|

|||

|

Page Title:

Piston and Connecting Rod, Reassembly and Installation |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

(3) Install connecting rod bearing shells (10,

(4) Install a piece of feeler stock (fig. 11-24)

0.0005 inch (0.012 mm) thick across connecting rod

bearing shell.

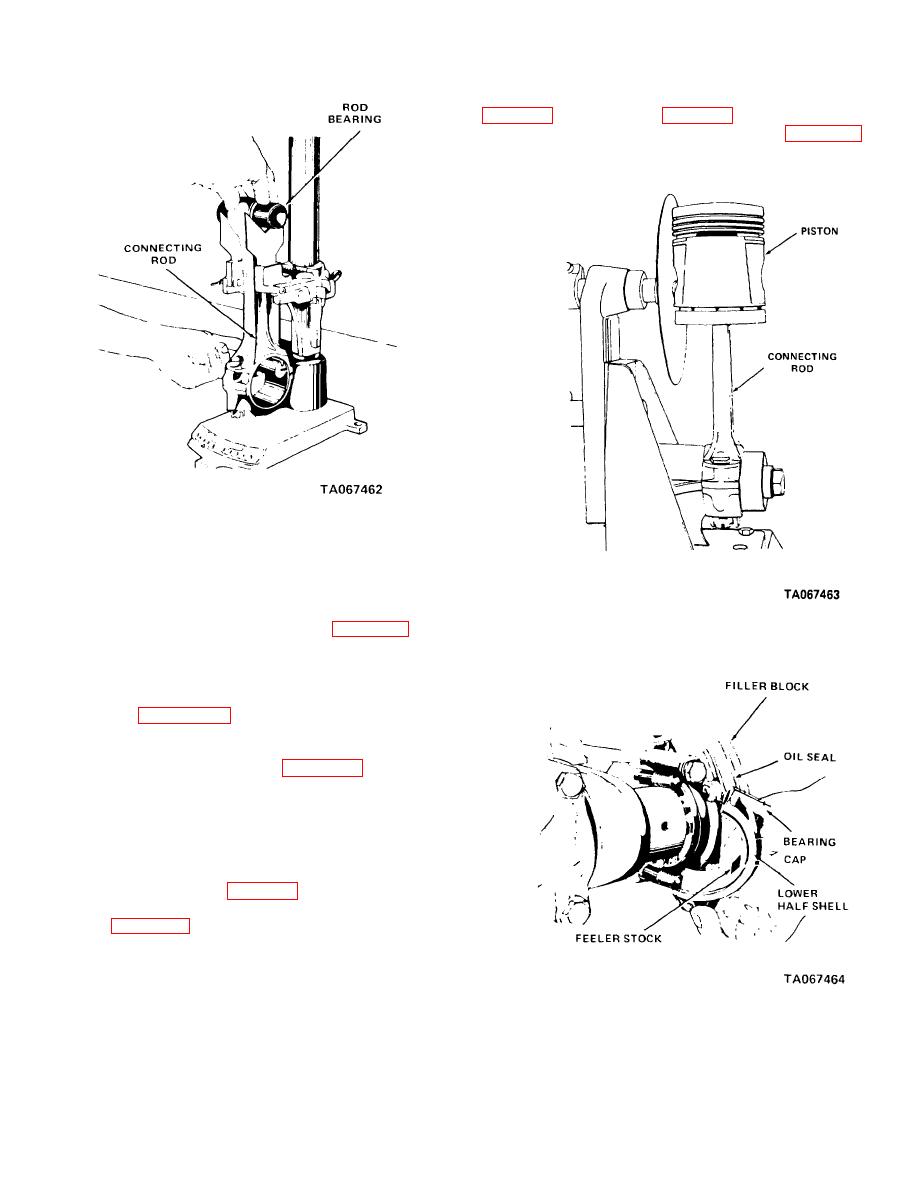

Figure 11-22. Checking connecting rod alignment.

(6) Straighten rod if possible.

Replace

excessively bent or twisted rods.

(7) Remove piston pin front connecting rod.

Heat piston in oven to a minimum temperature of 160 F

Figure 11-23. Checking connecting rod and piston.

(71 C). Install one retaining ring (2, fig. 11-18) in

piston. Install piston (4) on connecting rod (6) and slide

piston pin (3) through piston and rod.

Secure pin with two remaining retaining rings (8).

(8) Place assembled piston and rod in fixture

as shown in figure 11-23. Check alignment. Piston and

rod must not be more than 0.002 inch (0.05 mm) out of

square checked over a spread of four inches.

(9) Remove cap nuts (7, fig. 11-18), cap bolts

(8), bearing caps (9) and bearing shells (10) from

connecting rod.

11-19. Piston and Connecting Rod, Reassembly

and Installation

(1) Use a piston ring installer and install piston

rings (1, fig. 11-18) in correct grooves on piston.

(2) Check to see that piston is securely

attached to connecting rod and that both retaining rings

(2) are installed.

b. Installation.

Figure 11-24. Checking connecting rod bearing

(1) Coat piston and rings with oil (OE/HDO).

clearance with feeler gage stock.

(2) Use a piston ring compressor and install

assembled piston and rod into proper cylinder through

top of cylinder bore.

11-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |