|

|||

|

|

|||

|

Page Title:

Section III. PISTONS AND CONNECTING RODS |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

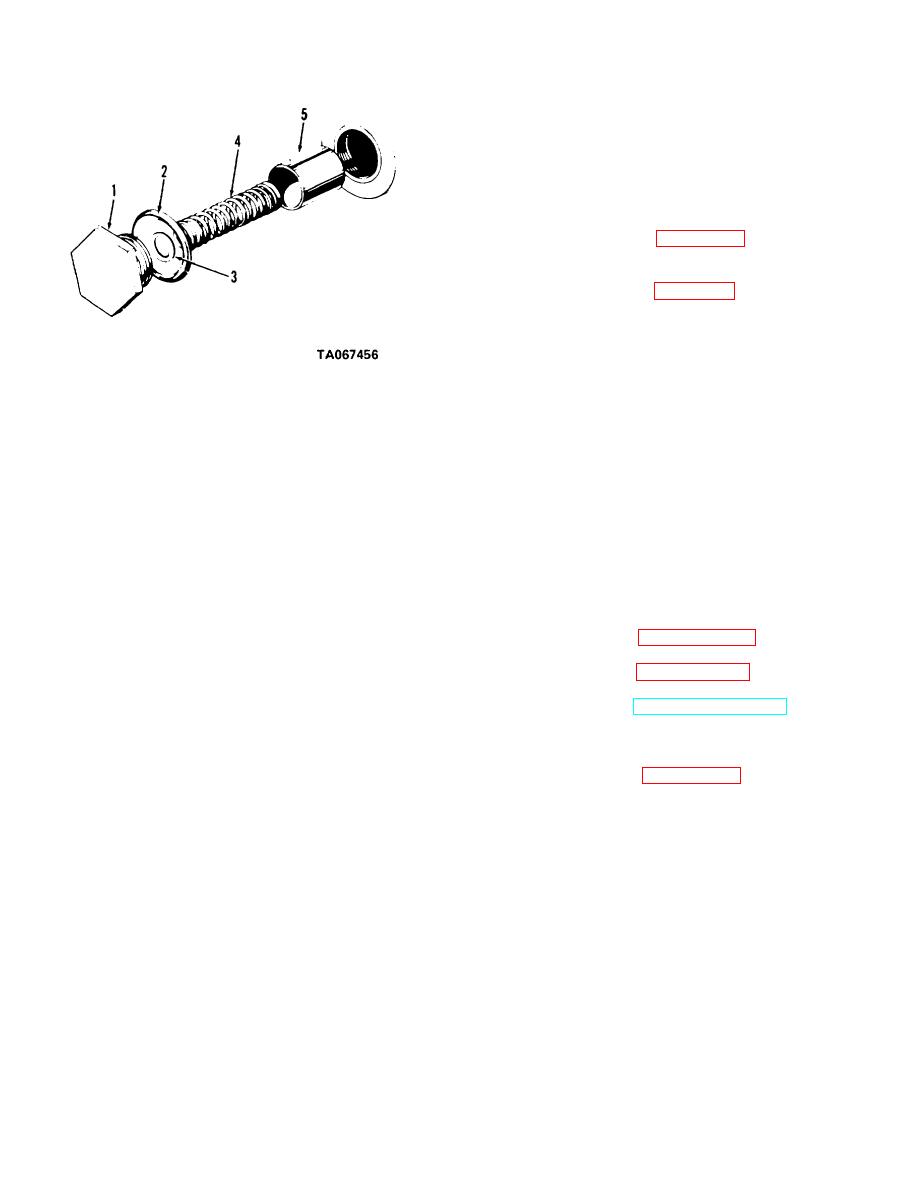

c. Inspect spring for cracks, damage and signs of

weakness.

d. Replace unserviceable parts.

11-15. Oil Pressure Relief Valve, Reassembly and

Installation

a. Reassembly and Installation. Reassemble and

install the oil pressure relief valve in reverse numerical

sequence as illustrated in figure 11-16.

b. Adjustment. Adjustment of the oil pressure

relief valve is accomplished by the removal and

installation of washers (3, fig. 11-16) behind spring (4).

(1) With engine at operating temperature, the

recommended pressure at idle speed is 5 to 10 psi (0.35

to 0.70 kg/cm2).

(2) With engine at operating temperature the

recommended pressure at full throttle is 30 to 40 psi (2.1

1 Plug

3 Washer

to 2.8 kg/cm2).

2 Gasket

4 Spring

(3) To increase pressure, add washers (3).

5 Valve

Add washers, one at a time, and check pressure. If after

Figure 11-16. Oil pressure relief valve, disassembly and

installing four washers, pressure is still low, replace

reassembly.

spring (4).

(4) To decrease pressure, remove washers.

11-14. Oil Pressure Relief Valve, Cleaning,

Remove washers, one at a time, and check pressure. If

Inspection and Repair

all washers are removed and pressure is still high,

a. Clean all metal parts in cleaning compound,

replace spring.

solvent (Fed. Spec. P-D-680) and dry thoroughly.

b. Inspect valve for dents, wear and damage.

Section III. PISTONS AND CONNECTING RODS

(1) Refer to paragraph 2-22 and remove the

11-16. Description

engine from the truck.

a. The connecting rods are precision ground and

(2) Refer to paragraph 11-7 and remove the

rifle drilled. They receive the thin-wall precision type

oil pan.

bearing shells to mount to the crankshaft.

(3) Refer to TM 10-3930-630-12 and remove

b. The aluminum pistons have four rings, two

the cylinder head.

compression rings, one scraper ring and one three piece

(4) Use a ridge cutting tool and remove ridge

oil control ring.

at top of piston bores.

(5) Refer to figure 11-17 and remove rod

11-17. Piston and Connecting Rods, Removal and

bearing cap nuts and connecting rod bearing caps and

Disassembly

bearing shells.

a. Removal.

(6) Slide piston and connecting rod up out

the top of the engine crank case.

11-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |