|

|||

|

|

|||

|

Page Title:

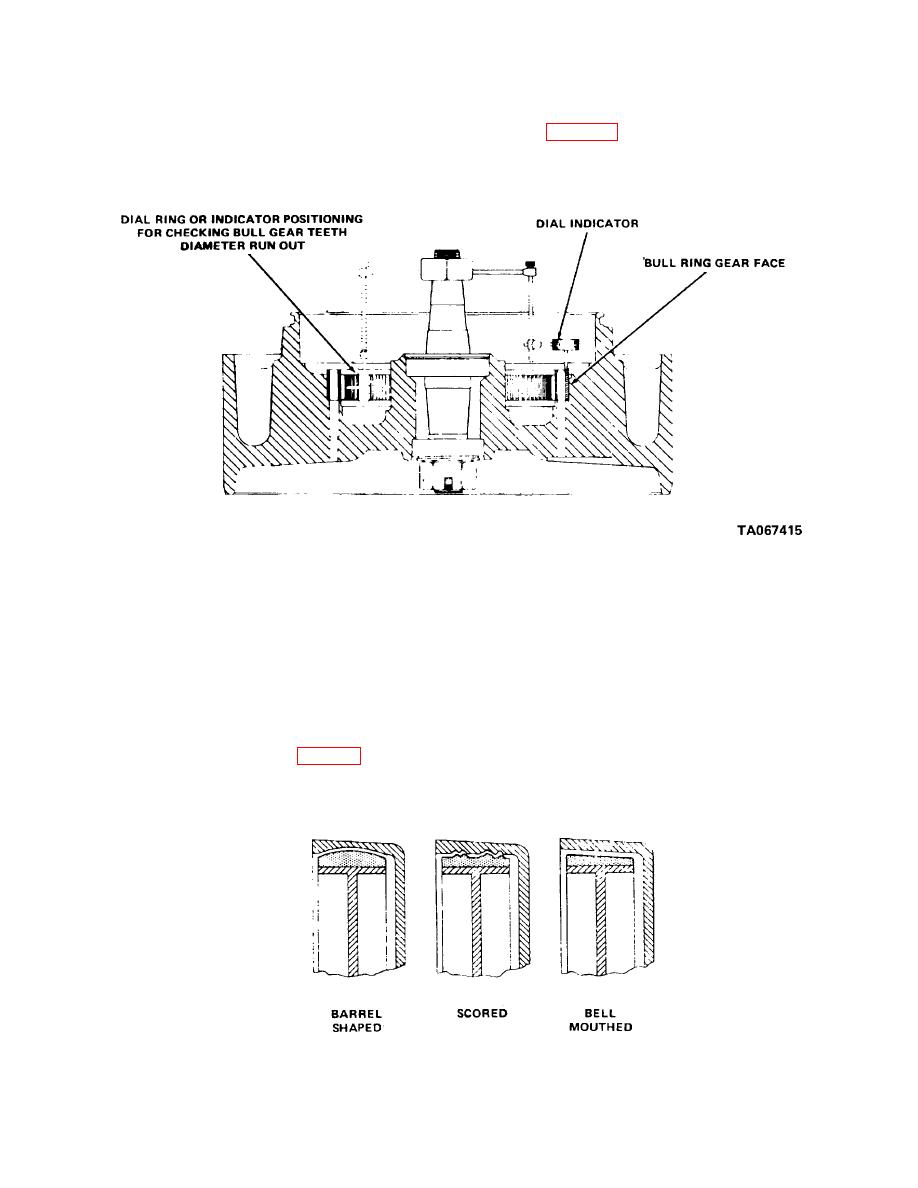

Figure 7-2. Checking bull gear face and teeth runout. |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

and damage.

damage is observed.

c. Check drive or bull gear for cracks, chips or other

(1) Check runout of bull gear teeth diameter as

shown in figure 7-2.

damage.

d. Check teeth of bull gear for wear, broken teeth

Figure 7-2. Checking bull gear face and teeth runout.

(0.254 mm) deep. Resurface drums that are heat

(2) Runout of bull gear face must not exceed

checked.

0.010 inch (0.254 mm).

(3) If drums do require resurfacing, resurface both

(3) Runout of inside diameter of bull gear face

drums. Finish grind or hone drums to remove tool

must not exceed 0.005 inch (0.127 mm).

marks, to prevent excessive lining wear and to avoid

e. Check inside diameter of brake shoes surface in

runout when brakes are applied.

drive wheel.

(4) Do not remove more than 0.050 inch (1.27

(1) Check inside diameter at points 45 degrees

mm) from a drum. Replace drum requiring deeper

apart. Resurface drum if measurements differ more

resurfacing. Maximum inside diameter after resurfacing

than 0.010 inch (0.254 mm).

will not exceed 11.053 inches (280.74 mm).

(2) Inspect lining wear pattern (fig. 7-3). Resurface

or reface bell-mouthed or barrel shaped drums. Scored

drums must be resurfaced if scoring is over 0.010 inch

TA067416

Figure 7-3. Improper lining wear pattern.

7-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |