|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-34

TA067399

Figure 4-2. Checking rotor.

(3) If coil or slip rings are not open, check

ohmmeter reading. Resistance should be approximately

3 ohms. If reading is low, coil is shorted. Replace rotor

(15) and regulator (17).

(4) Connect ohmmeter leads to one slip ring

and to rotor shaft. If reading is low, rotor coil is

grounded. Replace rotor (15).

c. Drive End Frame Test.

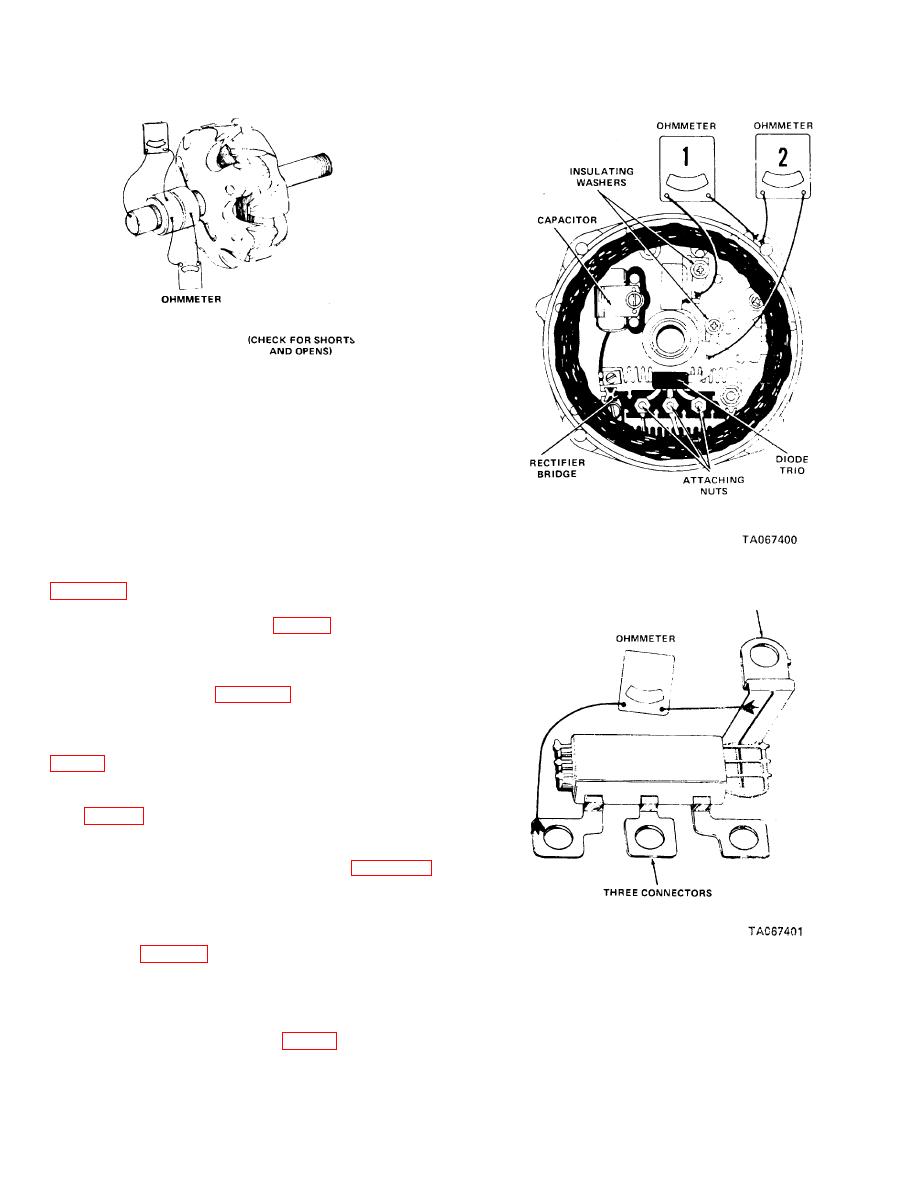

(1) Connect ohmmeter leads using

smallest range scale, as shown (ohmmeter No. 1) on

Figure 4-3. Checking drive end frame.

are the same, check for grounded brush lead clip to end

frame. Check insulating washers (fig. 4-3) and insulating

sleeve for damage. Replace insulating washers or

sleeve on the brush lead, if necessary.

(2) Connect ohmmeter leads as shown

for ohmmeter No. 2 on figure 4-3. Reverse connections.

If both readings are the same again check insulating

sleeve and replace if necessary. If insulation is correct

and both readings are the same, replace regulator (17,

d. Diode Test.

(1) Disconnect diode and remove nuts

(20, fig. 4-1) and remove diode (23) from end frame

(11).

(2) Use the lowest range on the

ohmmeter and connect leads as shown in figure 4-4.

Observe the reading. Reverse connections and again

check reading. If both readings are the same, replace

the diode.

(3) Repeat the test between the single

connector (fig. 4-4) and each of the other two

Figure 4-4. Diode test.

connectors. If readings are the same, replace the diode.

(4) Connect the ohmmeter between each

pair of the three connectors. If any reading is zero,

replace the diode.

(5) Install diode (23, fig. 4-1) in frame and

secure with nuts (20). Collect diode to brushes.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |