|

|||

|

|

|||

|

Page Title:

Section IV. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS AND ASSEMBLIES |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

Section IV. REMOVAL AND INSTALLATION OF MAJOR

COMPONENTS AND ASSEMBIES

eyes. Securely block truck in a raised position.

2-11. General

b. Refer to TM 10-3930-630-12 and drain the

hydraulic reservoir. Plug all hoses and tubes to avoid

a. The major components of the fork lift truck

dirt from entering the hydraulic system.

consist of the control valve, hydraulic pump, steering

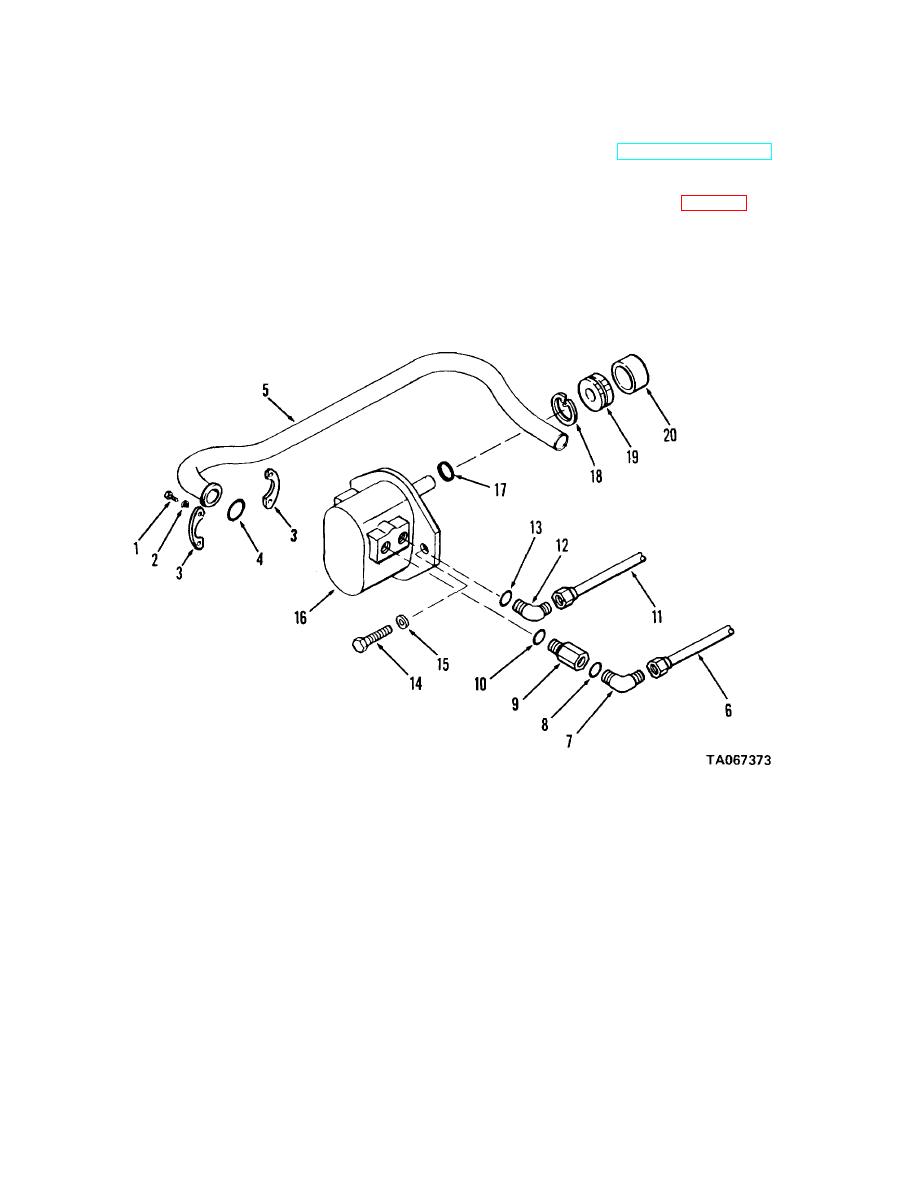

c. Remove screws (1, fig. 2-1) and lock washers

gear valve, engine assembly, service brakes, front drive

(2) and disconnect suction tube (5) from hydraulic pump.

axle,

rear steering axle and the transmission.

Remove split flanges (3) and packing (4). Plug

b.. The paragraphs in this section are for the

tube and pump to prevent entrance of foreign material.

removal and installation of the above components.

d. Disconnect steering hose (6) from elbow (7)

and remove elbow, check valve (9) and packings (8 and

2-12. Hydraulic Pump, Removal

10) from pump. Plug steering hose and pump opening.

a.

Raise up the rear of the truck with a hoist of at

least 6,000 pound capacity attached to the lifting

TA067373

1 Screw

6 Steering hose

11 Outlet hose

16 Hydraulic pump

2 Lock washer

7 Elbow

12 Elbow

17 Packing

3 Split flange

8 Packing

13 Packing

18 Retaining ring

4 Packing

9 Check valve

14 Screw

19 Hydraulic pump gear

5 Suction tube

10 Packing

15 Lock washer

20 Sleeve

Figure 2-1. Hydraulic pump, removal and installation.

e. Disconnect large outlet hose (11) from elbow

2-13. Hydraulic Pump, Cleaning and Inspection

(12) and remove elbow and packing (13) from pump.

Plug outlet hose and pump opening.

a. Clean hydraulic pump in cleaning solvent,

f. Remove screws (14) and lock washers (15)

(Fed. Spec. P-D-680). Dry thoroughly with compressed

and carefully remove hydraulic pump (16) from engine

air.

gear cover. Remove packing (17).

b. Inspect pump for cracks, breaks, or other

g. Remove retaining ring (18) and pump gear

damage.

(19) from sleeve.

2-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |