|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM10-3930-628-12

(3) Remove retaining rings and remove lever

4-52. Control Levers and Linkage

shaft from brackets and levers.

a. General. Two control levers, connected to the

(4) Remove levers and spacing washers.

control valve by linkages, actuate the lift and tilt cylinders.

(5) Install new levers, with shaft through

Movement of the levers opens ports in the valve to allow

brackets, levers and spacing washers. Secure shaft with

hydraulic pressure to flow to the cylinders. A switch,

retaining rings.

normally open, is mounted on a bracket behind the

(6) Connect yokes to levers with screws and

control rods. When a control lever is moved, the

self-locking nuts.

actuator contacts and closes the switch and starts the

hydraulic pump motor. Remove sheet metal cover to

gain access to linkage.

b. Lever Adjustment. Refer to figure 4-32 and

adjust linkage as follows:

(1) Remove screws and nuts attaching yokes

to control levers or to control valve.

(2) Loosen yoke lock nuts and adjust yokes on

rods to shorten or lengthen linkage.

(3) Linkage-should be adjusted to allow the

least amount of free play. When adjustment is complete,

control valve plungers must be in the neutral position

when levers are released.

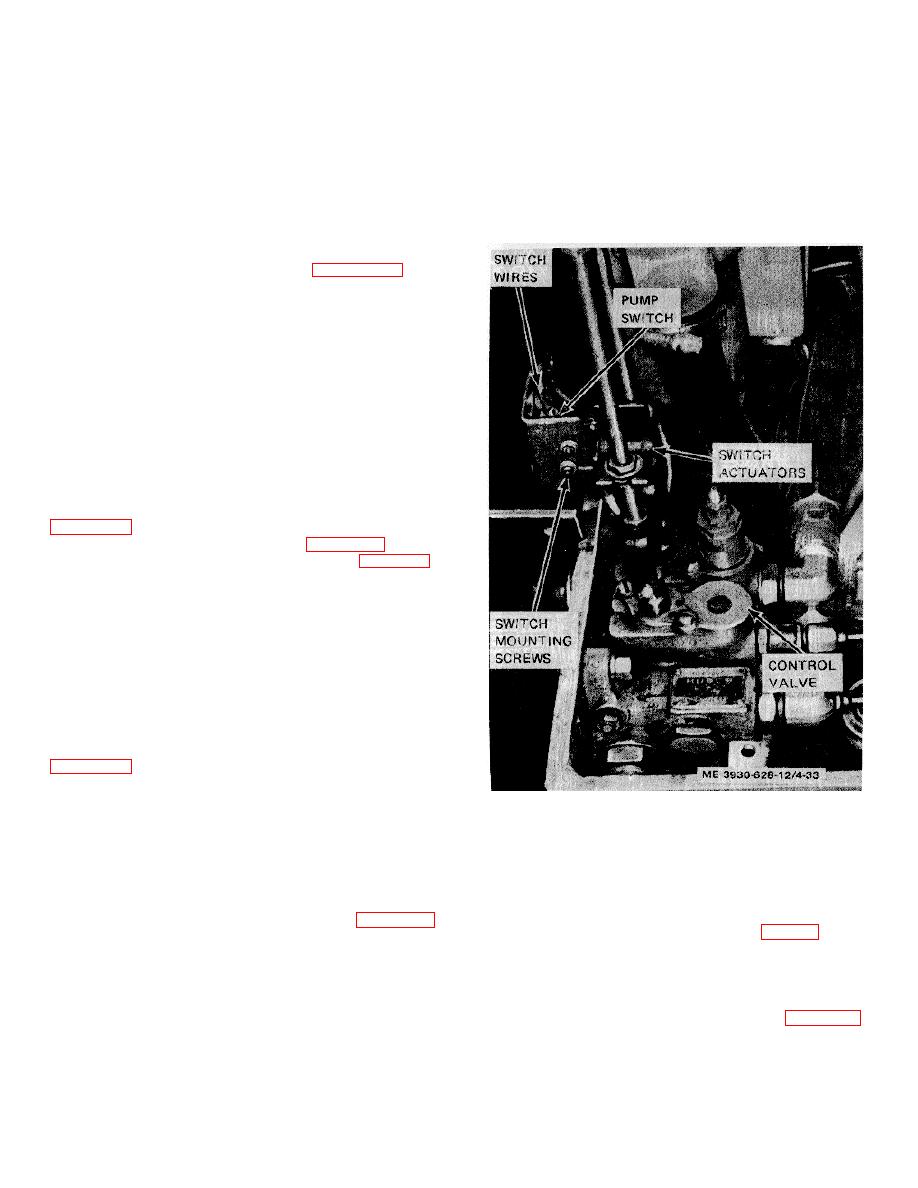

c. Switch Adjustment. Switch actuators must be

adjusted to have switch open when plungers are in

neutral position. Adjustment must be such that the

actuators close the switch with little movement of the

control lever. Disconnect battery receptacle. Refer to

(1) Move control levers (fig.

4-32) as if

operating lift and tilt mechanisms. Switch (fig. 4-33)

should close with an audible click after little movement.

(3) Loosen switch mounting screws and move

switch in or out as required. Switch roller should just

touch groove in actuators. Tighten switch mounting

screws.

(4) Move control levers and check adjustment.

(5) Connect battery receptacle and check

operation.

Pump should operate before cylinders

extend.

d. Switch Replacement. If switch requires re-

placement, disconnect battery receptacle and refer to

(1) Disconnect wires from switch. (2) Remove

two mounting screws and remove switch.

Figure 4-33. Hydraulic pump switch, installed view.

(3) Install new switch and secure with

mounting screws.

4-53.

Tilt Cylinder

(4) Connect wires to switch.

(5) Check and adjust switch (c above) to

a. General. Two tilt cylinders, one on each side of

assure proper operation.

the frame, provide power to tilt the mast.

(6) Connect battery receptacle.

b. Removal. Remove the tilt cylinder as follows:

d. Control Lever Replacement. Refer to figure 4-32

(1) Operate the tilt control lever (fig. 2-2) to tilt

and replace control levers as follows:

the mast forward. Connect a chain hoist to the mast to

(1) To replace lever knobs, remove knob from

hold it in a forward position.

lever.

(2) Remove floor and toe plates. Remove drip

(2) To replace lever, remove screw and self-

pan from underside of truck.

locking nut to disconnect lever from yoke.

(3) Disconnect hose assemblies (fig. 4-34)

from elbows in underside of cylinder. Plug hose and

cylinder ports.

(4) Support cylinder with a block of wood.

4-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |