|

|||

|

|

|||

|

Page Title:

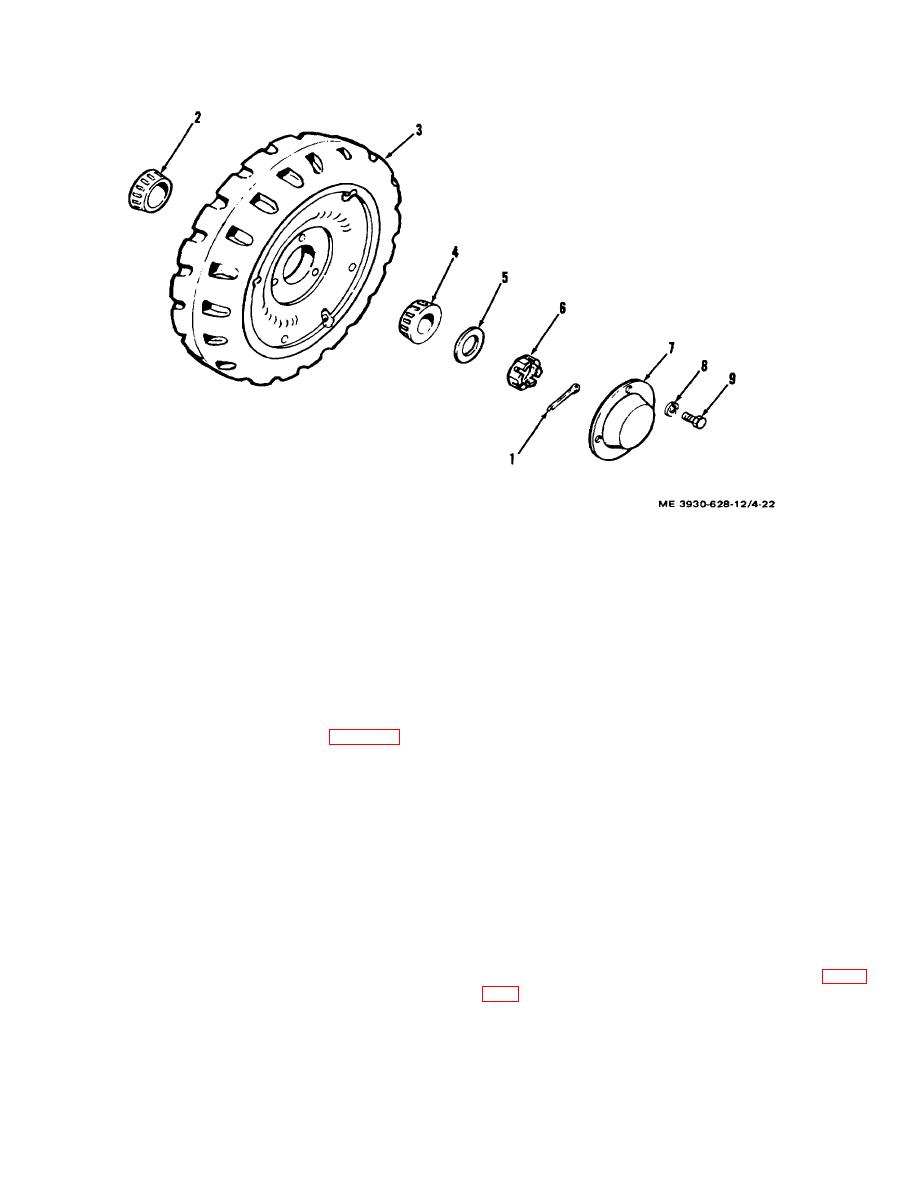

Figure 4-22. Drive wheel, exploded view. |

|

||

| ||||||||||

|

|

TM 10-3930-628-12

1. Cotter pin

2. Inner wheel bearing

3. Wheel and tire assembly

4. Outer wheel bearing

5. Washer

6. Wheel nut

7. Hub cap

8. Lock washer

9. Screw

Figure 4-22. Drive wheel, exploded view.

c. Inspection.

(4) Install wheel nut (6) and washer (5) on

(1) Inspect wheel and tire (3, fig. 4-22) for

spindle. Tighten nut and as nut is tightened rotate wheel

damage. Check teeth on ring or bull gear inside wheel

under power. Elevate truck. Block other wheel to

for damage.

prevent turning. Continue tightening nut until heavy drag

(2) Inspect brake drum for cracks, flat spots,

is felt while rotating wheel. Tighten nut to 50 foot-pounds.

excessive wear, and damage.

(5) Slowly loosen nut two flats and rotate

(3) Inspect bearings (2 and 4) and bearing

wheel. Loosen nut to a point where wheel rotates freely

cups in wheel for wear or damage.

and no bearing end play is evident.

(4) Clean bearings and bearing surfaces with

(6) Install cotter pin (1) to secure nut.

cleaning compound, solvent (Fed. Spec. P-D-680).

(7) Install hub cap (7) and secure with three

d. Front Wheel Installation. Refer to figure 4-

screws (9) and lock washers (8).

22 and install the wheel assembly as follows:

(8) Tilt mast backward to lower wheel to floor.

(1) Replace the inner and outer bearings (2

Remove block from under mast.

and 4) with grease (GAA).

e. Rear Wheel Removal. Use a suitable jack

(2) Install inner bearing (2) on axle spindle, with

and raise rear of truck until wheels clear the floor. Block

tapered side out.

front wheels to prevent truck from rolling. Refer to figure

(3) Install wheel assembly (3) on bearing and

spindle. Hold wheel assembly in place and install outer

(1) Remove three screws (9) and lock washers

wheel bearing (4) on spindle and inside rwheel, tapered

18) and remove hub cap (7).

side in.

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |