|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

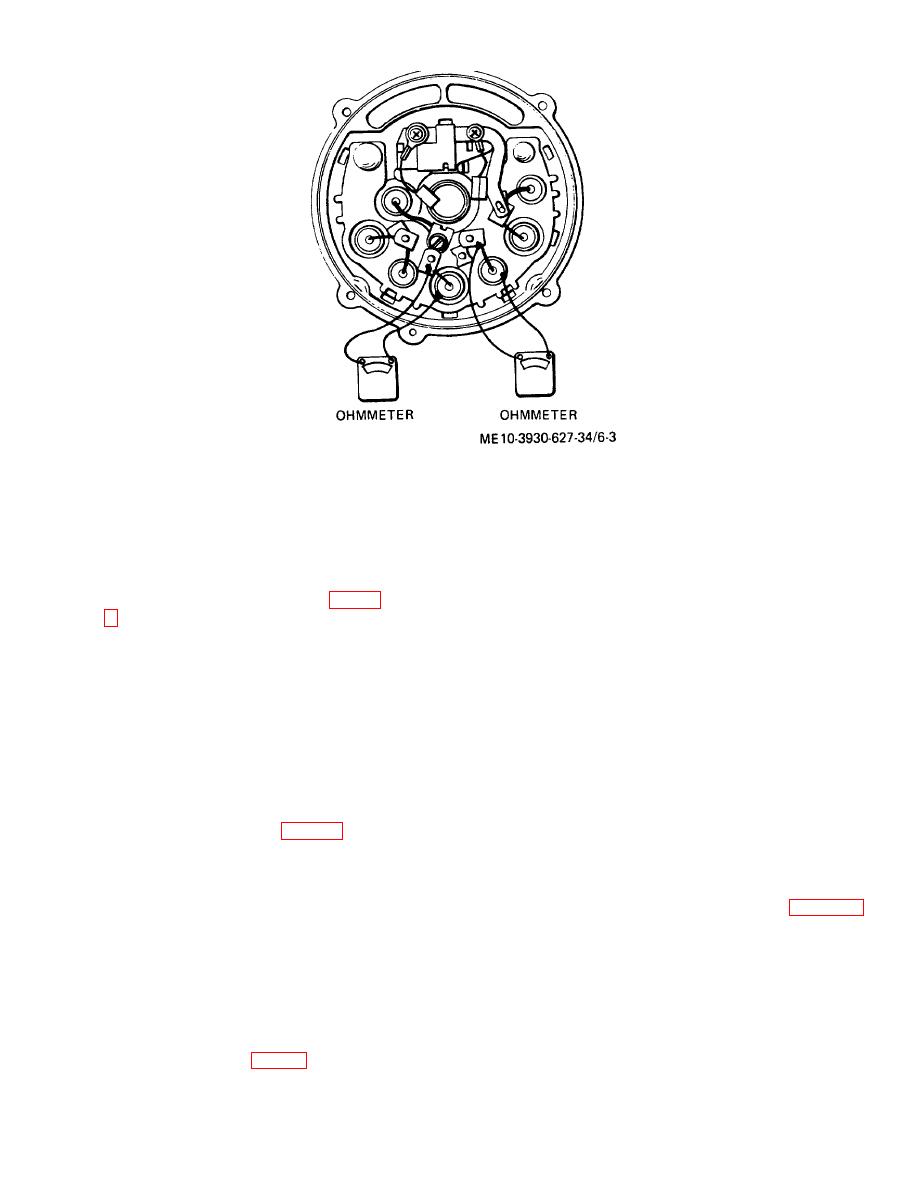

Figure 6-3. Diode Check.

and bearing retainer (25). Secure bearing retainer with

Caution: Do not attempt to polish

three screws (26).

slip rings without rotating rotor as

b. If bearing (4) has exhausted its lubricant, replace

they must be polished evenly.

bearing. Press it out of frame with tube or collar that

Cleaning by hand may result in flat

just fits inside frame bore. Press from outside of

spots which will cause brush noise.

housing toward inside. Place flat plate over new bearing

Inspect slip rings on rotor (7, fig. 6-

and press it in from outside of frame toward inside until

it is just flush with outside of frame. Support inside of

polishing cloth, 400 grain or finer.

frame with hollow cylinder to avoid breakage. Use

Spin rotor in lathe or equivalent, and

extreme care to avoid misalignment or placing undue

hold polishing cloth against slip

stress on bearing. Saturate felt seal of retainer (5) with

rings until they are clean.

OE 20 and assemble it in frame.

c. Check brushes to see if they have come in contact

o. Check slip rings for roughness or out-of-round. If

with lubricant. If so, wipe brushes with a soft, dry cloth.

they are rough or out-of-round, they should be trued on

Check brush springs (19) for damage or corrosion. If

a lathe to 0.002 inch tolerance. Remove only enough

there is any doubt as to condition of springs, replace

material to make rings smooth and round. Finish by

them. If new brushes are to be installed, remove brush

polishing with a cloth, 400 grain or finer. Blow all dust

holder assembly from frame by removing brush holder

from rotor and rings after polishing.

screws (18). Remove brushes and springs from brush

holders. Install new brush springs and brushes and

bearing retainer (25) to drive frame (10); remove inside

insert a straight wire or pin into hole at bottom of brush

collar (28) and gasket (27). Press bearing (20) from

holder to retain brushes. Position assembled brush

drive frame; remove grease slinger (30).

holder on frame and secure with two screws. Make sure

Caution: Do not fill bearing more

parts are in correct relationship as shown in figure 6-1.

than one-quarter full or it may

Allow straight wire or pin to protrude through hole in end

overheat.

Do not use any other

frame.

lubricant than lubricant specified. If

bearing is in satisfactory condition,

procedure. Make sure to remove tape from rotor shaft

fill it one-quarter full with lubricant.

and frame bearing. When holding rotor in a vise to

6-3. Alternator Assembly

install rotor in frame, tighten vise only tight enough to

a. Install grease slinger and press bearing in drive

permit torquing nut (32) to 50 to 60 foot-pounds.

frame, using a tube or collar that just fits over outer

Withdraw wire used when assembling

race. Install new gasket (27, fig. 6-1), inside collar (28),

6-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |