|

|||

|

|

|||

|

Page Title:

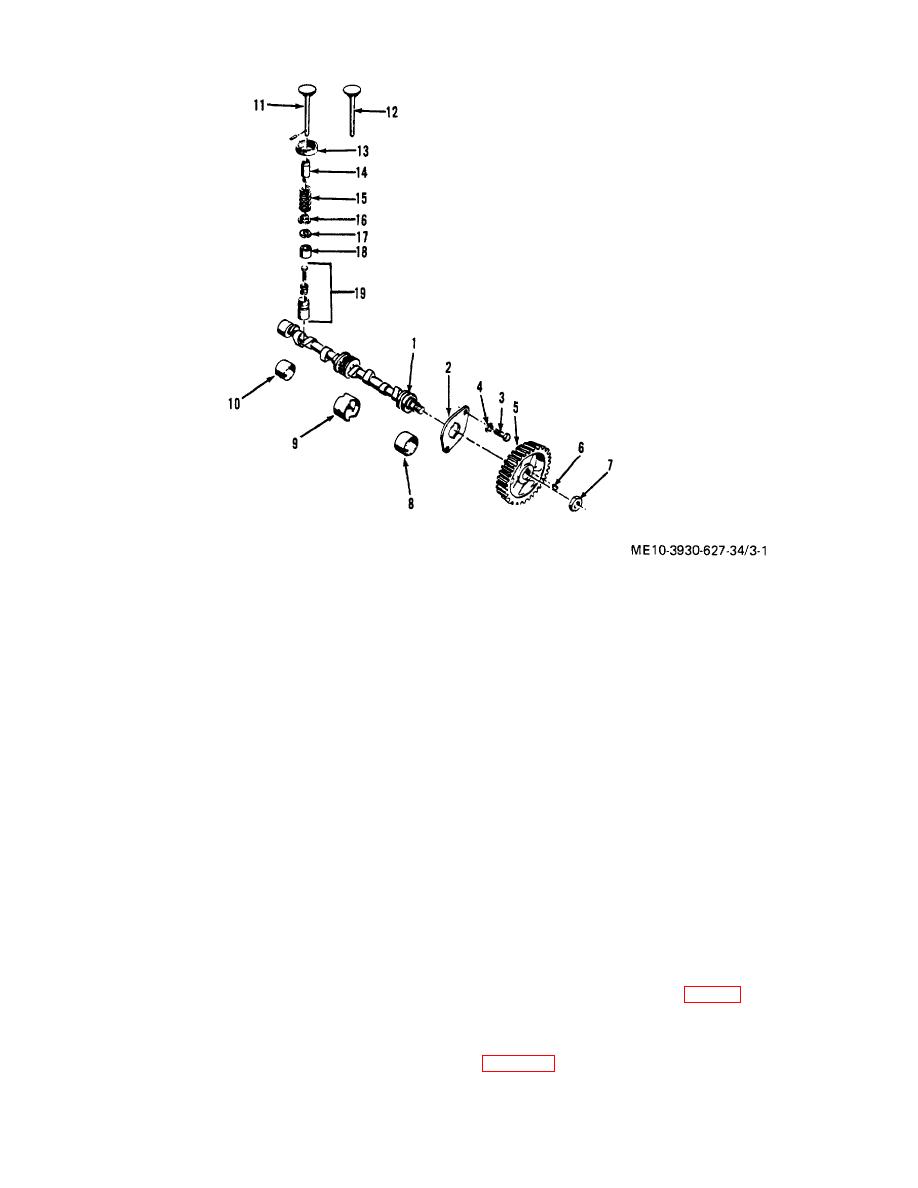

Figure 3-1. Values and camshaft, exploded view. |

|

||

| ||||||||||

|

|

1.

Camshaft

11. Intake valve

2.

Thrust plate

12. Exhaust valve

3.

Screw

13. Exhaust seat insert

4.

Washer

14. Guide

5.

Camshaft gear

15. Spring

6.

Woodruff key

16. Spring retainer

7.

Nut

17. Spring retainer lock

8.

Front camshaft bushing

18. Roto cap assembly

9.

Center Camshaft bushing

19. Tappet assembly

10.

Rear camshaft bushing

Figure 3-1. Values and camshaft, exploded view.

b. Cleaning and Inspection.

(5) Inspect exhaust valve seat inserts (13).

Replace inserts if loose or scored, or if they cannot be

(1) Clean carbon from valves with scraper or wire

properly faced (step d. below).

brush and wash in solvent. Clean valve guides (14) and

ports with wire brush.

(6) Inspect tappets for worn threads, scores,

(2) Replace valves if the faces are badly cracked,

cracks and wear or pitting of the face.

scored, warped or burned. Reface valves and seats if

(7) Examine adjusting screws for worn or

slight evidence of these conditions exists. Intake valve

damaged threads. Adjusting screws must be tight in

seat angle is 30and exhaust valve seat angle is 45

tappets when turned with a wrench. Replace them if

they are worn or damaged.

(3) Test valve springs for loss of strength. A

c. Valve Guide Replacement.

reusable valve spring will require at least 86 pounds

(1) Using a drift or piloted driver, drive old valve

force to compress it to 1 27/64 inch length. Inspect

guide from the cylinder block (fig. 3-2).

springs for cracks or breaks.

(2) Using a piloted driver, drive new guide into

(4) Inspect valve stems for good condition and

the cylinder block. Drive guide until its top is 1 15/32

proper clearance in valve guides. Replace valve if stem

inch from the top of the block, as measured according to

is bent over 0.002 inch. If inside diameter of any guide

is worn, to more than 0.0015 inch oversize, replace

valve guide (step c. below).

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |