|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-627-12

(3) If the thermostat opens before the

(7) Loosen outlet (lower) radiator hose

water temperature reaches 1600F. or does not open

clamp and separate hose from water pump (7) and from

until after the water temperature reaches 1800F., it

radiator. Disconnect remaining hoses from radiator.

should be replaced.

(8) Remove mounting capscrews and lock

c. Inspection. Inspect adapter for deterioration.

washers, remove adjusting strap cap screws, and

remove water pump (7) and gasket from engine block.

Inspect elbow .(housing) for cracks and thread for

(Bottom cap screw has copper washer.)

damage.

d. Installation. Reverse procedure in a above,

(9) Remove screws at sides of radiator and

remove radiator.

using a new gasket between the elbow and the cylinder

b. Inspection.

head. Make sure split in adapter aligns with bypass hole

(1) Inspect the pump for secure mounting.

in elbow.

(2) Inspect the water pump bearing for

4-30. Water Pump, Fan, Belt, and Radiator

noise.

a. Removal.

(3) Inspect the fan for secure mounting,

(1) Loosen alternator adjusting strap bolt at

bent or cracked blades.

water pump.

(4) Inspect the fan belt for wear, frays, and

(2)

Loosen alternator mounting bolts

proper adjustment of /2 inch finger-pressure deflection at

securing to mounting support and remove belt from

midpoint between the crankshaft pulley and the fan

alternator and crankshaft pulleys.

pulley.

(3) Work fan belt (6, fig. 4-11} over fan (1)

c. Installation. Reverse steps of a above, in-

and rotate fan until belt can be removed from the fan.

stalling a new water pump gasket. Refill cooling system.

(4) Remove screws (8) and lockwashers

d. Adjustment of Belt.

that secure fan to hub. Remove fan (1).

(1) Loosen the alternator adjusting strap

(5) Drain radiator.

bolt and the alternator mounting bolts.

(6) Disconnect recirculating tube (4) at

(2) Pivot alternator for desired belt tension

water pump and at thermostat elbow and remove from

(b (4) above) and tighten adjusting strap bolt and

engine.

alternator mounting bolts.

Section X. ELECTRICAL SYSTEM

specified output of 14 volts. Check amperage at 2000

4-31. Alternator

alternator rpm or 1000 engine rpm (cold); it should be 21

a. Removal.

amperes. Check amperage at 5000 alternator rpm or

(1) Disconnect wiring harness and ground

2500 engine rpm (cold); it should be 30 amperes.

lead at front of alternator.

Operate alternator until it is at operating temperature.

(2) Remove attaching screw at adjusting

Check output amperage; it should be 32 amperes

strap (fig. 4-11 ) and screws at mounting bracket, and lift

maximum.

off alternator.

b. Installation.

(1) Position alternator on mounting bracket

and install screws attaching alternator to mounting

bracket and adjusting strap.

(2) Install drive belt on alternator pulley,

and adjust drive belt tension so that drive belt can be

deflected one-half inch by finger pressure at midpoint

between drive and driven pulleys. To adjust tension,

loosen cap screw that holds adjusting strap to alternator

and loosen screws that hold alternator to mounting

bracket. To tighten, use bar to pry alternator away from

engine to achieve correct tension; then tighten adjusting

strap cap screw. Tighten mounting screws.

(3) Reconnect wiring harness and ground

lead to alternator.

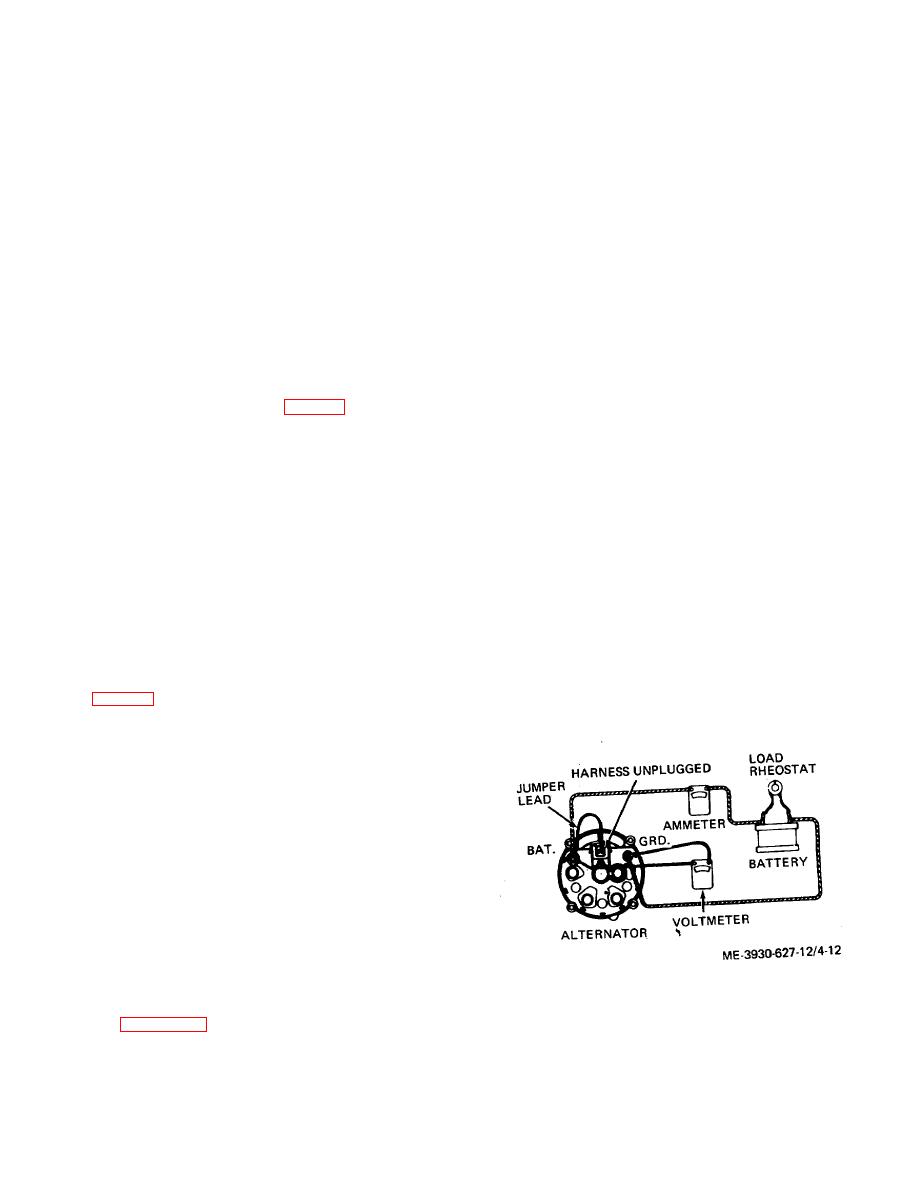

Figure 4-12. Alternator test setup.

c. Test.

(1)

Connect assembled alternator as

shown in figure 4-12. Make sure negative terminal is

connected to ground. Adjust load rheostat to obtain

4-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |