|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-627-12

b. Installation. Reverse procedure in a. above.

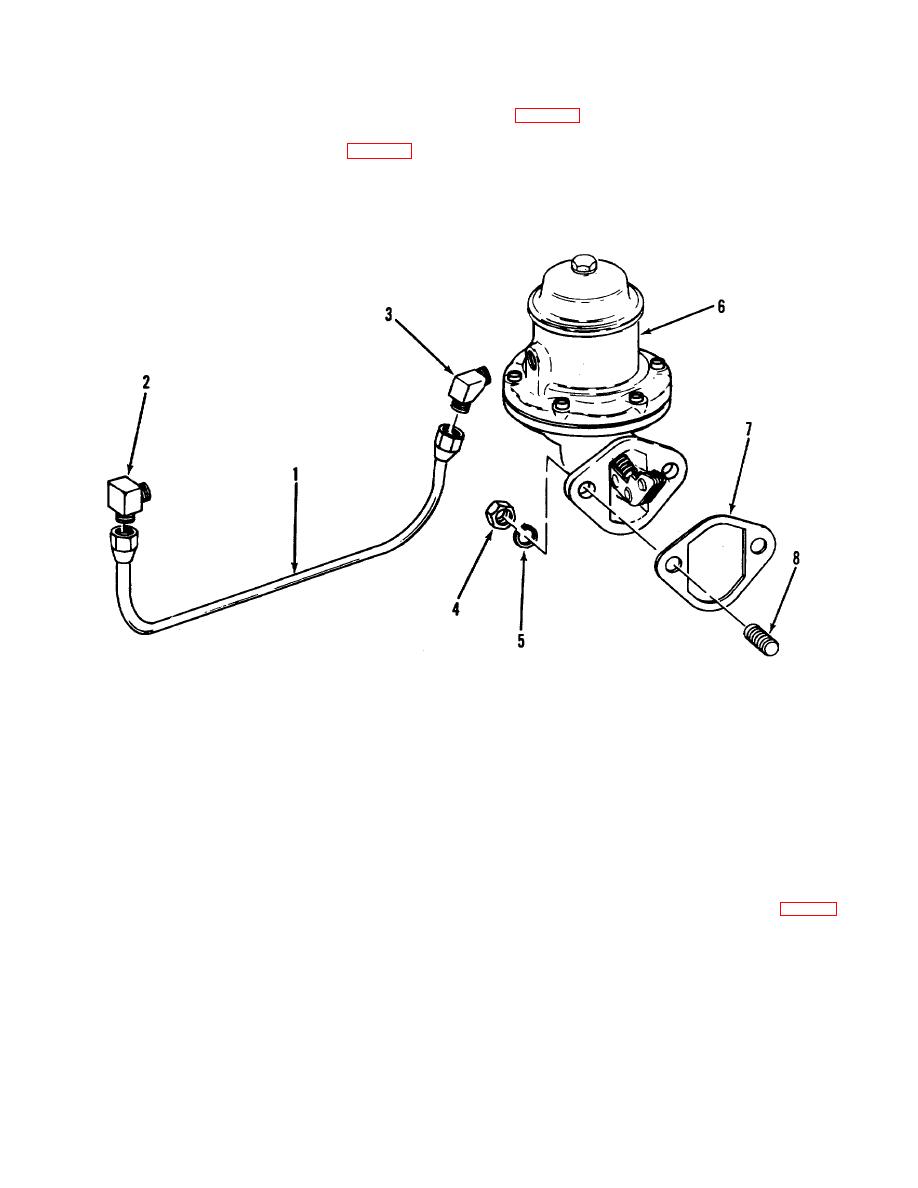

(3) Disconnect pump to carburetor fuel line

(12, fig. 4-11) at carburetor elbow (11) and fuel pump

4-26. Fuel Pump

elbow (13). Remove elbow (13).

a. Removal.

(4) Working from under truck, remove nuts

(1) Close fuel shut off cock (6, fig. 4-10) at

(10), washers (9), from studs (8) and remove fuel pump

fuel filter (5).

(6) and gasket (7) from engine block.

(2) Disconnect fuel pump inlet line (2) at

fuel pump.

1.

Fuel line

5.

Washer

2.

Elbow

6.

Fuel pump

3.

Elbow

7.

Gasket

4.

Nut

8.

Stud

Figure 4-8. Fuel pump.

c. Installation. Using new gasket, reverse

below the minimum number, replace the fuel pump with

a serviceable one.

removal procedure.

d. Pressure Test. To perform pressure test on

(7) Remove the gage, tachometer and tee

fitting.

the fuel pump, proceed as follows:

(1) Install a tee fitting in the line between

4-27. Fuel Filter Assembly

the fuel pump and the carburetor.

a. Inspection and Cleaning.

(2) Install a pressure gage in the tee fitting.

(1) Inspect fuel filter assembly (fig. 4-9) for

(3) Install a tachometer on the engine.

cracks, breaks, leaks, and secure mounting.

(4) Run the engine at 1, 800 rpm.

(2) Loosen the nut (7) that secures bowl to

(5) The pump pressure should register

filter, swing the bail (6) to one side, and remove the bowl

from 12 to 31/4 psi (pounds per square inch).

(5), gasket (4), element (3), and gasket (2).

(6) If the static pressure reading is above

(3) Clean the bowl and element thoroughly

the maximum number of pounds per square inch or

4-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |